System for preparing gel bead

A gel ball and gel technology, which is applied in the preparation of microspheres, microcapsule preparations, and the reduction of greenhouse gases, can solve the problems of inconvenient container processing and on-site operation, limited space for storing gel balls, and increased infrastructure costs. Effects of reduced deformation, reduced stress, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

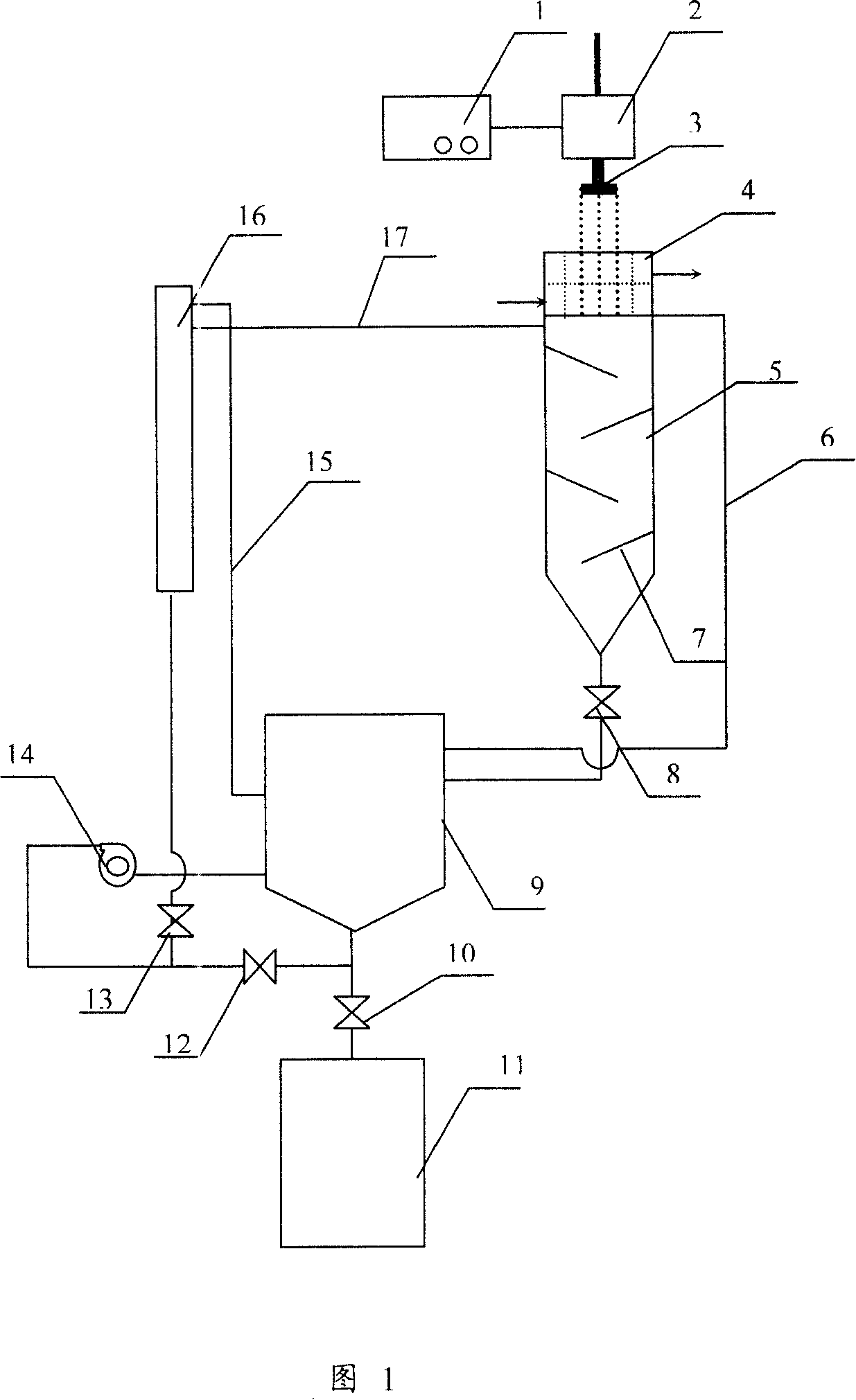

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] It can be seen from Figure 1 that the whole set of gel ball preparation equipment includes two parts: a vibration dispersion system and a gel system. The vibration dispersion system includes a signal controller 1 , a vibrator 2 and a nozzle 3 . The signal generated by the signal controller 1 is transmitted to the vibrator 2, and the nozzle 3 is driven to vibrate according to the input amplified signal.

[0025] The gel system includes an ammonia gas distribution ring 4, a gel column 5, a liquid tank 9, a buffer column 16, and a ball storage tank 11, wherein the ammonia gas distribution ring 4 is independent from the gel column 5, and the ammonia gas distribution ring 4 is located in the condensation Above the gel column 5, the lower end of the gel column 5 is connected to the upper side of the liquid tank 9 through a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com