Preparation method for activated carbon material and application thereof

A technology of activated carbon and carbon materials, applied in the chemical industry, can solve the problems of uneven distribution of activator and difficult activation process, and achieve the effect of improving activation effect, broad application prospect and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

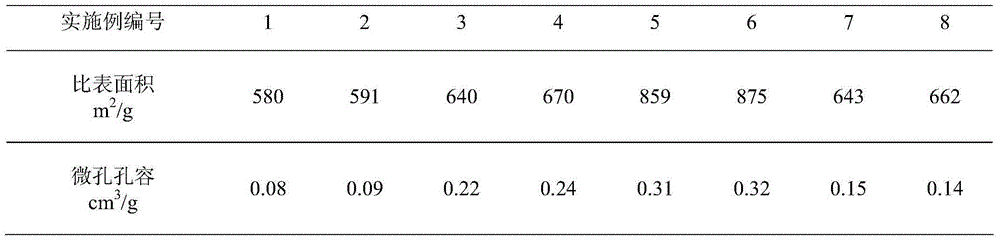

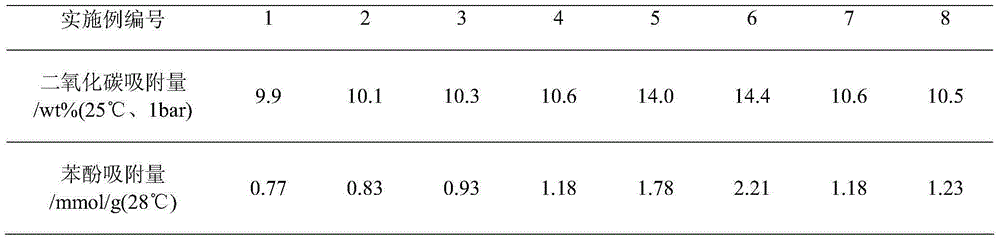

[0047] Measure 001×7 ion exchange resin and KOH aqueous solution with a concentration of 1mol / L at a volume ratio of 1:2, stir and mix at 30°C for 32 hours, and replace the KOH solution every 8 hours. Then it was washed with deionized water until neutral, filtered, and dried at 100°C to obtain K + doped resin. Take 10gK + Doped resin in N at a flow rate of 100mL / min 2 Carbonization was carried out at 500°C for 3 hours in the atmosphere, and the heating rate was 5°C / min. Then, the carbon material prepared above was washed with 0.1 mol / L HCl solution for 2 hours, then washed with deionized water until neutral, filtered and dried at 100°C to obtain activated carbon material sample 1#. The texture properties of activated carbon material sample 1# are shown in Table 1.

Embodiment 2

[0049] Measure 001×7 ion exchange resin and KOH aqueous solution with a concentration of 1mol / L at a volume ratio of 1:2, stir and mix at 30°C for 32 hours, and replace the KOH solution every 8 hours. Then it was washed with deionized water until neutral, filtered, and dried at 100°C to obtain K + doped resin. Take 10gK + The doped resin was pre-oxidized in air at a flow rate of 100 mL / min at 200 °C for 1 hour, and then in N at a flow rate of 100 mL / min. 2 Carbonization was carried out at 500°C for 3 hours in the atmosphere, and the heating rate was 5°C / min. Then, the carbon material prepared above was washed with 0.1 mol / L HCl solution for 2 hours, then washed with deionized water until neutral, filtered and dried at 100°C to obtain activated carbon material sample 2#. The texture properties of activated carbon material sample 2# are shown in Table 1.

Embodiment 3

[0051] Measure 001×7 ion exchange resin and KOH aqueous solution with a concentration of 1mol / L at a volume ratio of 1:2, stir and mix at 30°C for 32 hours, and replace the KOH solution every 8 hours. Then it was washed with deionized water until neutral, filtered, and dried at 100°C to obtain K + doped resin. Take 10gK + Doped resin in N at a flow rate of 100mL / min 2 Carbonization was carried out at 600°C for 3 hours in the atmosphere, and the heating rate was 5°C / min. Then, the carbon material prepared above was washed with 0.1 mol / L HCl solution for 2 hours, then washed with deionized water until neutral, filtered and dried at 100°C to obtain activated carbon material sample 3#. The texture properties of activated carbon material sample 3# are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com