A method for preparing activated carbon for supercapacitors by using acid residue pitch

A technology of acid residue pitch and super capacitor, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of high price and low specific surface area of graphene, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

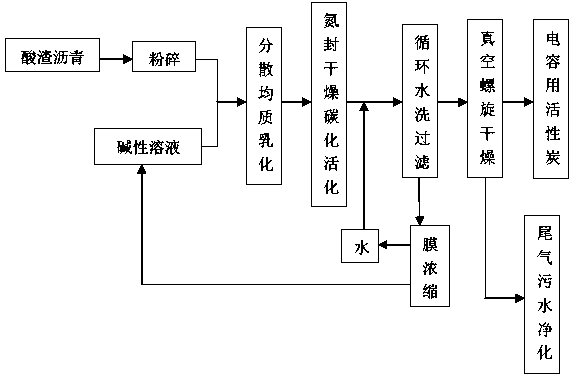

Image

Examples

Embodiment 1

[0031] This embodiment relates to a method for preparing activated carbon for supercapacitors using acid slag pitch, which specifically includes the following steps:

[0032] Step (1): crush the acid residue asphalt, and screen the acid residue asphalt powder with a particle size of 300-500 mesh;

[0033] Step (2): According to the ratio of acid residue asphalt powder: lye = 1:1, the acid residue asphalt powder is mixed in a 50% potassium hydroxide aqueous solution, and dispersed and homogeneously emulsified to obtain acid residue asphalt Emulsions with lye;

[0034] Step (3): Drying: Put the emulsion into the activation furnace, heat up to 120°C at a rate of 5°C / min, keep it warm for 40 minutes, dry and dehydrate; carbonization activation: under the protection of nitrogen, continue to heat up at 5°C / min Raise the temperature to 900°C at a certain rate, keep it warm for 6 hours, and cool down after completing carbonization and activation;

[0035] Step (4): Wash the activate...

Embodiment 2

[0038] This embodiment relates to a method for preparing activated carbon for supercapacitors using acid slag pitch, which specifically includes the following steps:

[0039] Step (1): crush the acid residue asphalt, and screen the acid residue asphalt powder with a particle size of 300-500 mesh;

[0040] Step (2): According to the ratio of acid residue asphalt powder: lye = 1:2, the acid residue asphalt powder is mixed in potassium hydroxide aqueous solution with a mass fraction of 50%, and dispersed, homogeneous and emulsified to obtain acid residue Emulsions of bitumen and lye;

[0041] Step (3): Drying: Put the emulsion into the activation furnace, heat up to 140°C at a rate of 20°C / min, keep it warm for 30 minutes, dry and dehydrate; carbonization activation: under the protection of nitrogen, continue to heat up at 20°C / min Raise the temperature to 600°C at a certain rate, keep the temperature for 6 hours, and cool down after carbonization and activation;

[0042] Step ...

Embodiment 3

[0045] This embodiment relates to a method for preparing activated carbon for supercapacitors using acid slag pitch, which specifically includes the following steps:

[0046] Step (1): crush the acid residue asphalt, and screen the acid residue asphalt powder with a particle size of 300-500 mesh;

[0047] Step (2): According to the ratio of acid residue pitch powder: lye = 1:1, mix the acid residue pitch powder in saturated potassium carbonate solution, disperse and homogeneously emulsify, and obtain the emulsion of acid residue pitch and lye turbid liquid;

[0048] Step (3): Drying: Put the emulsion into the activation furnace, heat up to 160°C at a rate of 10°C / min, keep it warm for 40 minutes, dry and dehydrate; carbonization activation: under the protection of nitrogen, continue to heat up at 10°C / min Raise the temperature to 700°C at a certain rate, keep the temperature for 7 hours, and cool down after carbonization and activation;

[0049]Step (4): Wash the activated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com