Laser additive manufacturing method of in-situ synthesized nano Al2O3 reinforced aluminum-based composite material

A technology of laser additive and manufacturing methods, which is applied in the direction of additive processing, process efficiency improvement, and energy efficiency improvement. The refinement of the structure, the improvement of mechanical properties, and the effect of eliminating hole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The aluminum-based composite material of this embodiment is specifically prepared according to the following steps:

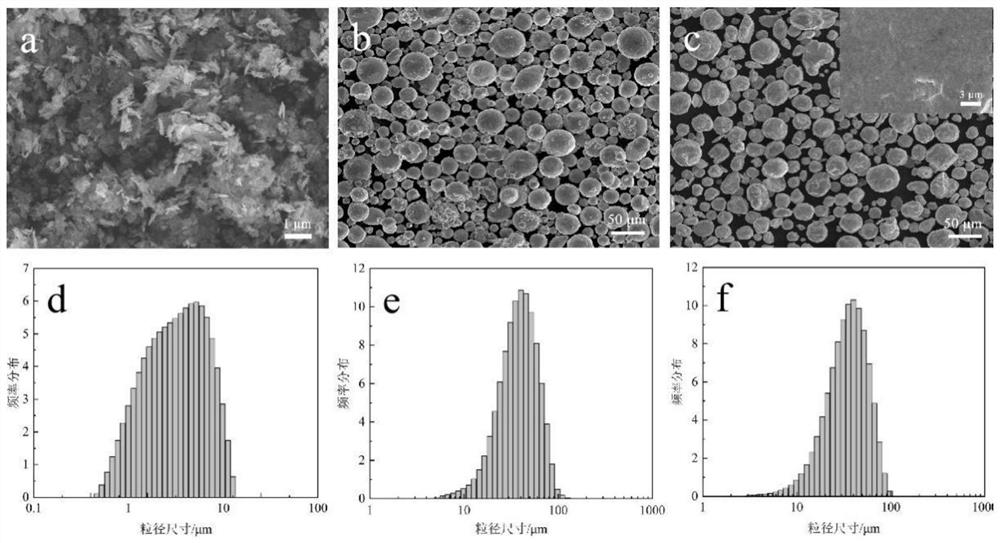

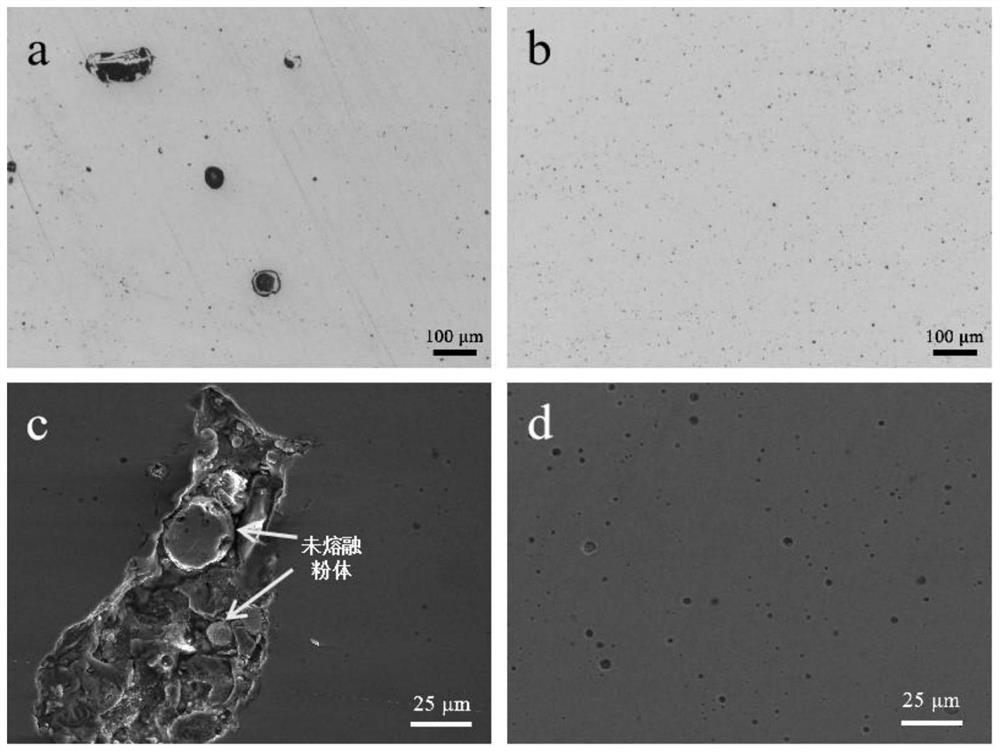

[0044] (1) 3g of ZnO ceramic powder and 97g of AlSi10Mg aluminum alloy powder were weighed and mixed to form a mixture. Among them, the ZnO powder has an irregular shape and a particle size of 0.5-12 μm. The SEM morphology and particle size distribution are shown in figure 1 a in and figure 1 In d; the AlSi10Mg aluminum alloy powder is spherical, with a particle size of 5-127 μm, and its SEM morphology and particle size distribution are shown in figure 1 b in and figure 1 e in

[0045] Then the mixture is placed in a ball mill for ball milling, and the ball milling medium used is Al 2 o 3 For ceramic balls, the mass ratio of ball milling medium to raw material is 15:1; the ball milling process is intermittent, with each ball milling for 20 minutes, and the air cooling is suspended for 15 minutes. The total time of ball milling is 10 hours, and the b...

Embodiment 2

[0051] The aluminum-based composite material of this embodiment is specifically prepared according to the following steps:

[0052] (1) 3g of ZnO ceramic powder and 97g of AlSi10Mg aluminum alloy powder were weighed and mixed to form a mixture.

[0053] Then the mixture is placed in a ball mill for ball milling, and the ball milling medium used is Al 2 o 3 For ceramic balls, the mass ratio of ball milling medium to raw material is 15:1; the ball milling process is intermittent, with each ball milling for 20 minutes, and the air cooling is suspended for 15 minutes. The total time of ball milling is 10 hours, and the ball milling speed is 300r / min.

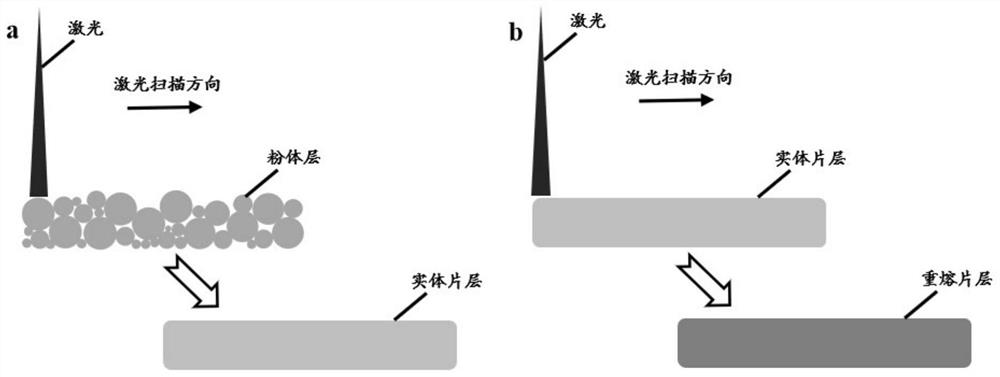

[0054] (2) Using the composite powder prepared in step (1) as raw material, the laser selective melting process is used for additive manufacturing and forming. First, the composite powder is evenly spread on the forming substrate through the powder spreading device, and then the powder is processed by laser The layers are scanned,...

Embodiment 3

[0059] The aluminum-based composite material of this embodiment is specifically prepared according to the following steps:

[0060] (1) 3g of ZnO ceramic powder and 97g of AlSi10Mg aluminum alloy powder were weighed and mixed to form a mixture.

[0061] Then the mixture is placed in a ball mill for ball milling, and the ball milling medium used is Al 2 o 3 For ceramic balls, the mass ratio of ball milling medium to raw material is 15:1; the ball milling process is intermittent, with each ball milling for 20 minutes, and the air cooling is suspended for 15 minutes. The total time of ball milling is 10 hours, and the ball milling speed is 300r / min.

[0062] (2) Using the composite powder prepared in step (1) as raw material, the laser selective melting process is used for additive manufacturing and forming. First, the composite powder is evenly spread on the forming substrate through the powder spreading device, and then the powder is processed by laser The layers are scanned,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com