Titanium and aluminum based alloy powder material for additive manufacturing and preparation method thereof

A powder material and additive manufacturing technology, which is applied in the field of titanium-aluminum-based alloy powder materials for additive manufacturing and its preparation, can solve the problems of prolonging the supply cycle, raising the price of powder raw materials, and restricting the development of the additive manufacturing industry. Achieve improved oxidation resistance, high strength and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

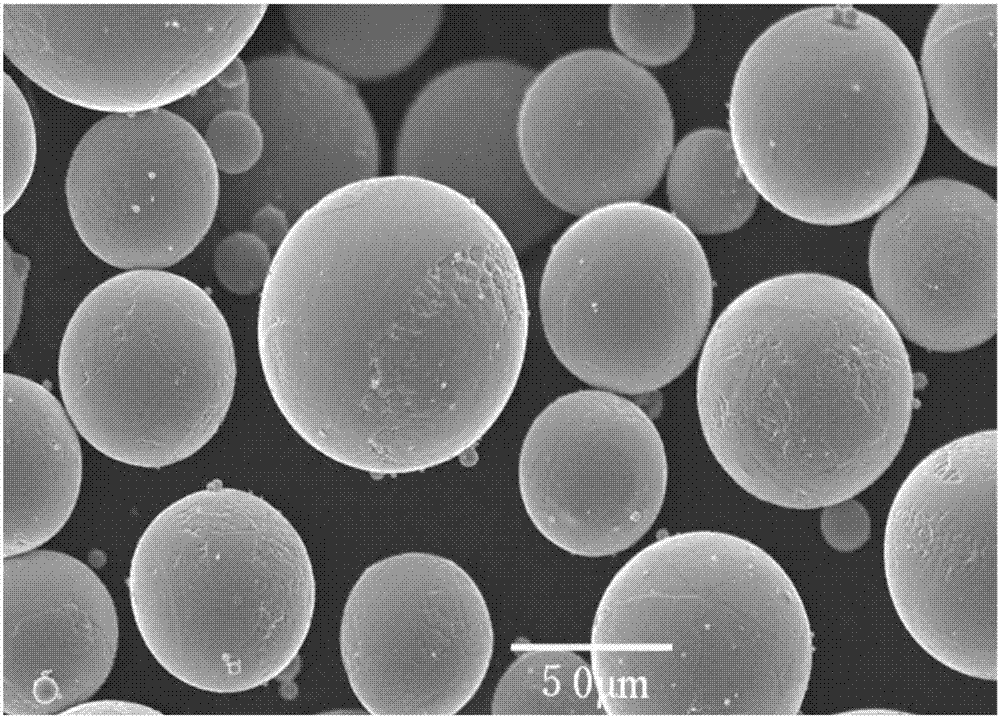

[0031] The titanium-aluminum-based alloy powder material for additive manufacturing in this embodiment is made of the following atomic percent raw materials: Al47%, Cr 2.3%, Mo 2.0%, TiB 2 1.0%, the balance is Ti and unavoidable impurities.

[0032] The method for preparing titanium-aluminum-based alloy powder material in this embodiment comprises the following steps:

[0033] Step 1. Protect the inner wall of the graphite flow guide tube in the vacuum induction melting gas atomization equipment by using the ceramic flow guide inner core. The ceramic powder is added into the mold and pressed into shape, and after sintering, a ceramic flow guide core compatible with the graphite flow guide tube is obtained, and then the ceramic flow guide core is nested inside the graphite flow guide tube; The first ceramic powder is ZrO 2 powder;

[0034] Step 2. Mix the second ceramic powder and absolute ethanol evenly to obtain an anti-high temperature carbonization coating, and apply th...

Embodiment 2

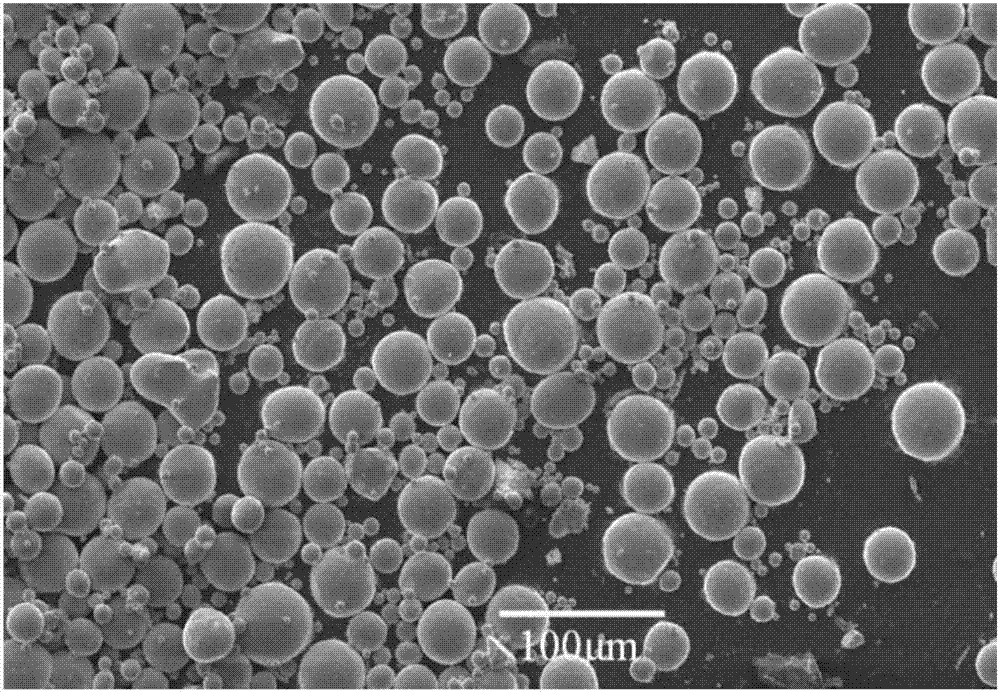

[0040] The titanium-aluminum-based alloy powder material for additive manufacturing in this embodiment is made of the following atomic percentages of raw materials: Al56%, Cr 1.6%, Mo 1.6%, TiB 2 1.2%, the balance is Ti and unavoidable impurities.

[0041] The method for preparing titanium-aluminum-based alloy powder material in this embodiment comprises the following steps:

[0042] Step 1. Protect the inner wall of the graphite flow guide tube in the vacuum induction melting gas atomization equipment by using the ceramic flow guide inner core. The ceramic powder is added into the mold and pressed into shape, and after sintering, a ceramic flow guide core compatible with the graphite flow guide tube is obtained, and then the ceramic flow guide core is nested inside the graphite flow guide tube; The first ceramic powder is Y 2 o 3 powder;

[0043] Step 2. Mix the second ceramic powder and absolute ethanol evenly to obtain an anti-high temperature carbonization coating, an...

Embodiment 3

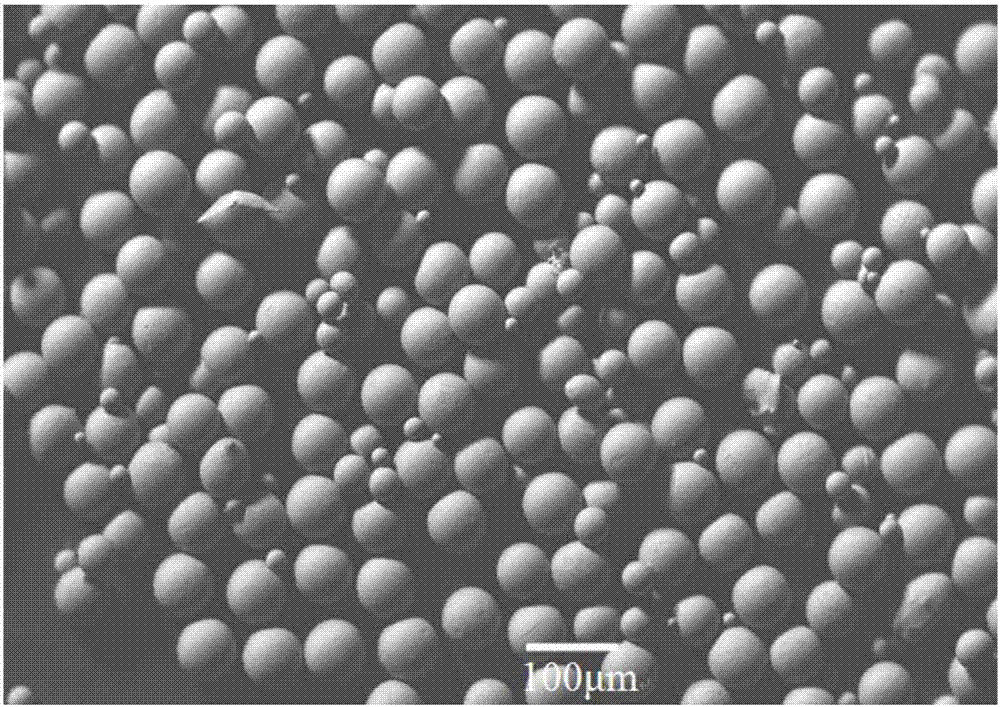

[0049]The titanium-aluminum-based alloy powder material for additive manufacturing in this embodiment is made of the following atomic percentages: Al50%, Cr 2.0%, Mo 2.0%, TiB 2 0.8%, the balance is Ti and unavoidable impurities.

[0050] The method for preparing titanium-aluminum-based alloy powder material in this embodiment comprises the following steps:

[0051] Step 1. Protect the inner wall of the graphite flow guide tube in the vacuum induction melting gas atomization equipment by using the ceramic flow guide inner core. The ceramic powder is added into the mold and pressed into shape, and after sintering, a ceramic flow guide core compatible with the graphite flow guide tube is obtained, and then the ceramic flow guide core is nested inside the graphite flow guide tube; The first ceramic powder is Y 2 o 3 powder;

[0052] Step 2. Mix the second ceramic powder and absolute ethanol evenly to obtain an anti-high temperature carbonization coating, and apply the anti-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com