Ground calcium carbonate for rare earth separation and saponification and preparation method of ground calcium carbonate

A heavy calcium carbonate, saponification technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment and other directions, can solve the problems of ion influence, prone to third phase, increased organic phase loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

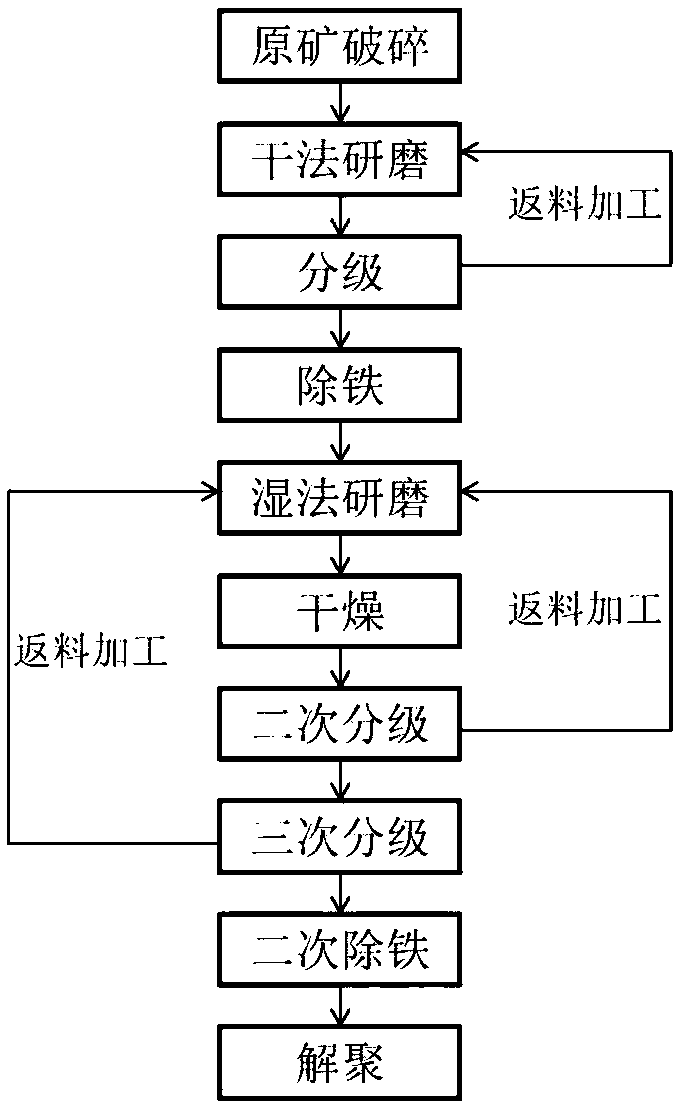

[0032] The specific implementation of this embodiment is shown in Figure 1, the raw ore is high-purity marble, and the specific steps include:

[0033] (1) Raw ore crushing: Put the bulk ore body in a jaw crusher for primary crushing to obtain small pieces of ore, wash and remove impurities from the small pieces of ore, dry them and place them in a crusher for secondary crushing, and obtain a particle size of 2~3cm particles.

[0034] (2) Dry grinding: the ore particles obtained in step (1) are ground in a vertical mill to obtain heavy calcium carbonate with a diameter in the range of 2 to 100 μm.

[0035] (3) Classification: Use a vibrating sieve to sieve and classify the above-mentioned heavy calcium carbonate. The powder with a diameter of 2-60 μm enters the next step, and the powder with a diameter greater than 60 μm returns to the previous step for regrinding.

[0036] (4) Iron removal: Iron removal treatment is performed on the heavy calcium carbonate with a diameter of...

Embodiment 2

[0048] The specific implementation of this embodiment is shown in Figure 1, the raw ore is high-purity calcite, and the specific steps include:

[0049] (1) Raw ore crushing: Put the bulk ore body in the jaw crusher for primary crushing to obtain small pieces of ore, wash the small pieces of ore to remove impurities, dry them and place them in the crusher for secondary crushing, and obtain a particle size of 2~3cm particles.

[0050] (2) Dry grinding: the ore particles obtained in step (1) are ground in a vertical mill to obtain heavy calcium carbonate with a diameter in the range of 2 to 100 μm.

[0051](3) Classification: Use a vibrating sieve to sieve and classify the above-mentioned heavy calcium carbonate. The powder with a diameter of 2-60 μm enters the next step, and the powder with a diameter greater than 60 μm returns to the previous step for regrinding.

[0052] (4) Iron removal: Iron removal treatment is performed on the heavy calcium carbonate with a diameter of 2...

Embodiment 3

[0064] The specific implementation of this embodiment is shown in Figure 1, the raw ore is high-purity marble, and the specific steps include:

[0065] (1) Raw ore crushing: Put the bulk ore body in the jaw crusher for primary crushing to obtain small pieces of ore, wash the small pieces of ore to remove impurities, dry them and place them in the crusher for secondary crushing, and obtain a particle size of 2~3cm particles.

[0066] (2) Dry grinding: the ore particles obtained in step (1) are ground in a vertical mill to obtain heavy calcium carbonate with a diameter in the range of 2 to 100 μm.

[0067] (3) Classification: Use a vibrating sieve to sieve and classify the above-mentioned heavy calcium carbonate. The powder with a diameter of 2-60 μm enters the next step, and the powder with a diameter greater than 60 μm returns to the previous step for regrinding.

[0068] (4) Iron removal: Iron removal treatment is performed on the heavy calcium carbonate with a diameter of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com