Metal powder preparation method and device based on plasma atomization technology

A metal powder and preparation device technology, applied in the direction of additive processing, etc., can solve the problems of mass production and low production efficiency of metal powder, and achieve the effect of avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

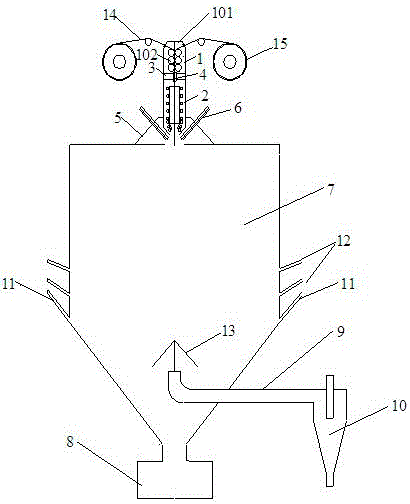

[0042] Such as Figure 1-4 As shown, the metal powder preparation device based on plasma atomization technology includes a feeding chamber 1, an induction heating melting chamber 2, a plasma torch chamber 5, an atomizing chamber 7 and a powder collection chamber 8,

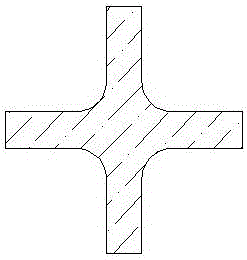

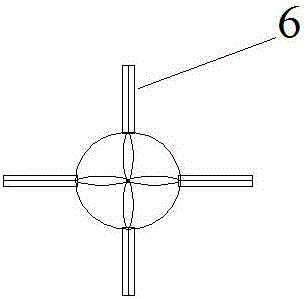

[0043] The upper end of the feeding chamber 1 is a dynamic sealing device 101. The interior of the feeding chamber 1 is equipped with a multi-channel wire continuous feeding mechanism and a straightening mechanism 102. The lower part of the feeding chamber 1 is an induction heating melting chamber 2. The feeding chamber 1 There is a partition 3 between the induction heating and melting chamber 2, a vertical wire guide pipe 4 runs through between the feeding chamber 1 and the induction heating and melting chamber 2, and the induction heating and melting chamber 2 is provided with an induction heating device And the magnetic confinement device, the induction heating device is an induction coil, the magnetic confinem...

Embodiment 2

[0049] Embodiment 2 Metal powder preparation method

[0050] The present embodiment selects 4 Ti-6Al-4V titanium alloy metal filaments 14 with a diameter of 10mm (such as figure 2 ), passing through the dynamic sealing device 101, the feeding mechanism and the straightening mechanism 102 respectively, the wire guide tube 4 transports the wire 14 to the induction heating melting chamber 2, and after the test is normal, turn off the power supply of the feeding system and close the feeding chamber . Then vacuumize the whole system, the vacuum degree reaches 1X10 -4 After Pa, high-purity argon is injected into the system to restore the gas pressure inside the equipment to normal pressure of 0.1Mpa. Turn on the induction heating device and the magnetic confinement device, and turn on the feeding device to make it work.

[0051] The metal wire 14 is vertically downward, preheated in the high-frequency electromagnetic field to close to the melting temperature, completely melted, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com