Ytterbium/gadolinium/yttrium ternary co-doped zirconium oxide nanostructure agglomerated sphere and production method thereof

A nanostructure and production method technology, applied in the field of ceramic materials, can solve problems affecting the stability and life of high-temperature service, and achieve the effects of easy control of process parameters, uniform particle size distribution, and high thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

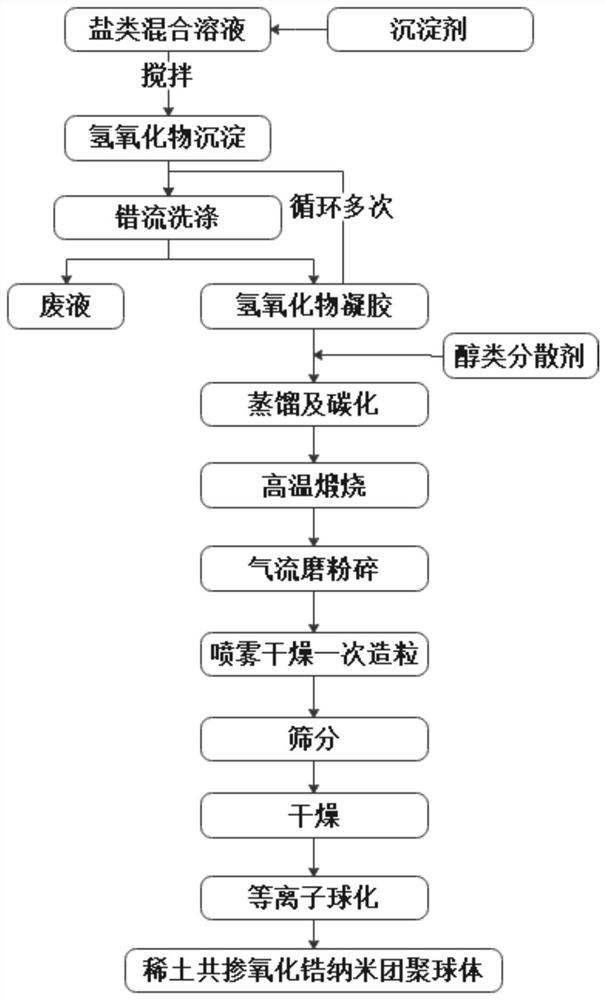

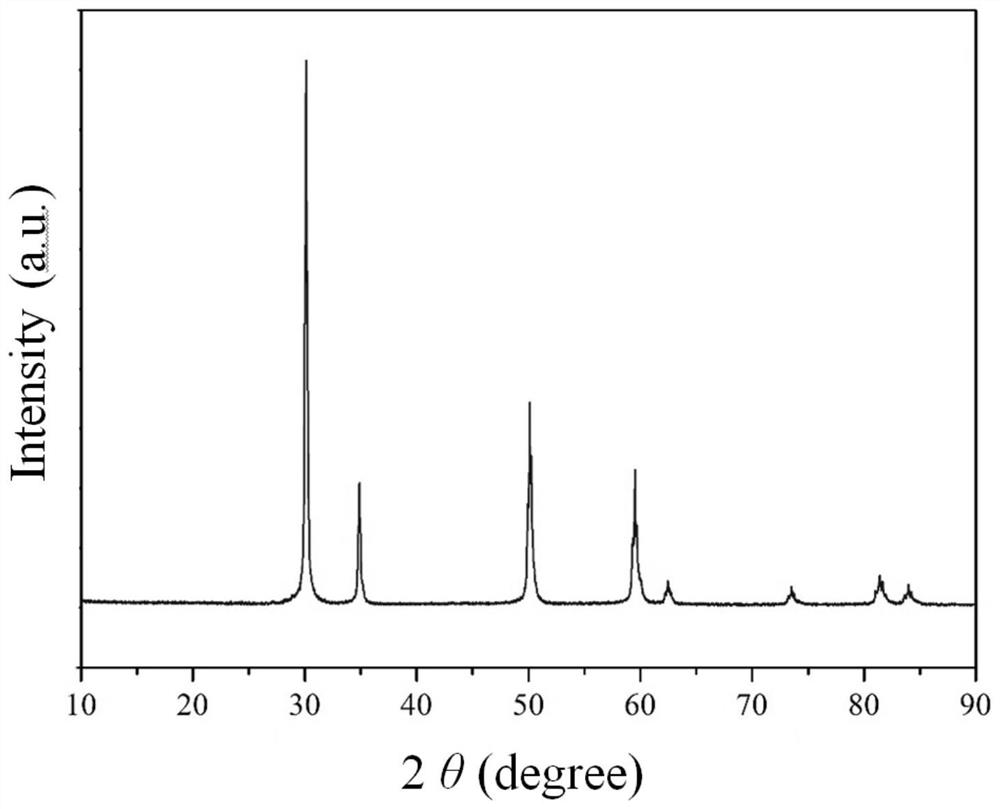

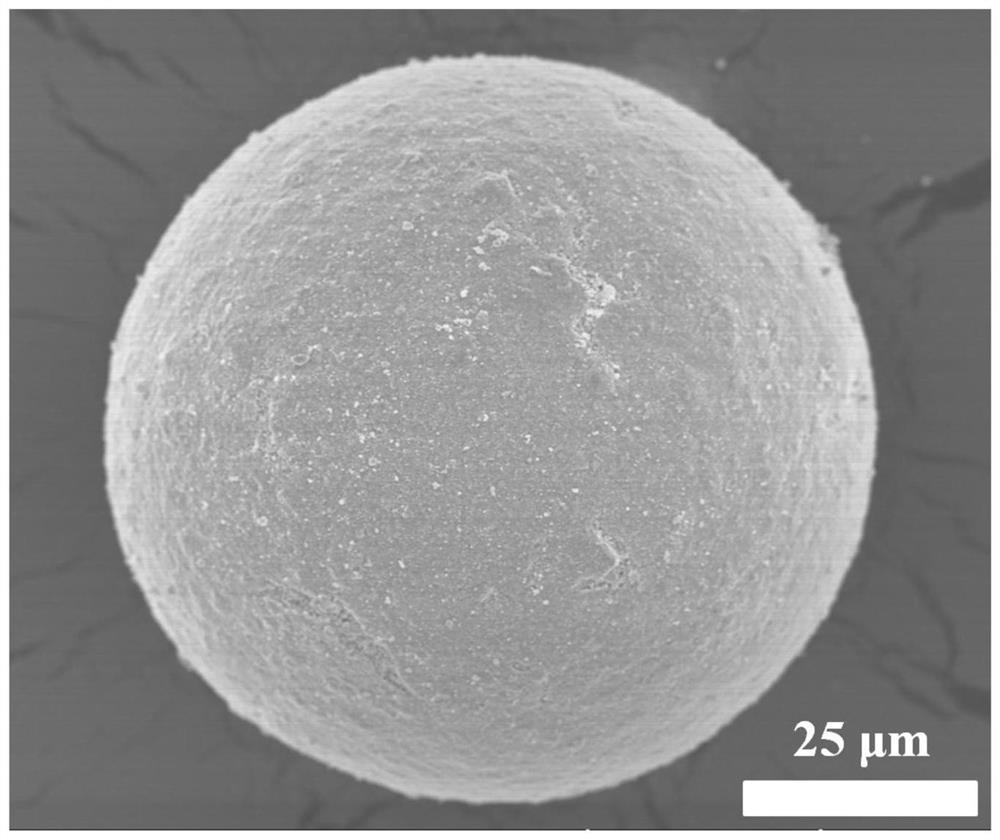

[0040] Such as figure 1As shown, yttrium nitrate, ytterbium nitrate and gadolinium nitrate were dissolved in deionized water to prepare a 0.2mol / L nitrate solution, and zirconium oxychloride was dissolved in deionized water to prepare a 0.5mol / L solution. The solutions were mixed in proportion to obtain a mixed solution with a molar ratio of yttrium ion:ytterbium ion:gadolinium ion:zirconium ion=20:10:10:60. The mixed solution was dropped dropwise into the ammonium oxalate solution to form a precipitate. Hydroxide precipitates were obtained after stirring and aging, wherein the stirring time was 2 hours, and the precipitation aging time was 12 hours. The precipitate is subjected to cross-flow washing treatment to remove impurity ions. Mix the washed hydroxide precipitate with n-butanol at a mass ratio of 1:3 and stir evenly, and place it in a dry distillation device at 150°C for azeotropic distillation, dehydration and drying. Then the powder was calcined in a high-temperat...

Embodiment 2

[0043] Mix 0.1mol / L yttrium nitrate, ytterbium nitrate and zirconium nitrate solution with 0.5mol / L zirconium oxychloride solution in proportion to obtain the molar ratio of yttrium ion:ytterbium ion:gadolinium ion:zirconium ion=2:2:1 : 95 mixed solution. The mixed solution was dropped dropwise into ammonia water with a volume concentration of 50% to form a precipitate. The pH value of the solution was kept at 9. After stirring for 2 hours, the solution was left to age for 24 hours. Subsequently, the obtained hydroxide colloid was subjected to repeated cross-flow washing until the pH value of the solution was 7 and there was no chloride ion in the solution (no precipitation after adding silver nitrate). Mix the washed hydroxide precipitate with isopropanol at a mass ratio of 1:2 and stir evenly, and place it in a dry distillation device at 200°C for azeotropic distillation dehydration and drying treatment. Then the powder was calcined in a high-temperature furnace at 1100° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com