Special binder for corundum slag pellets and its preparation and use method

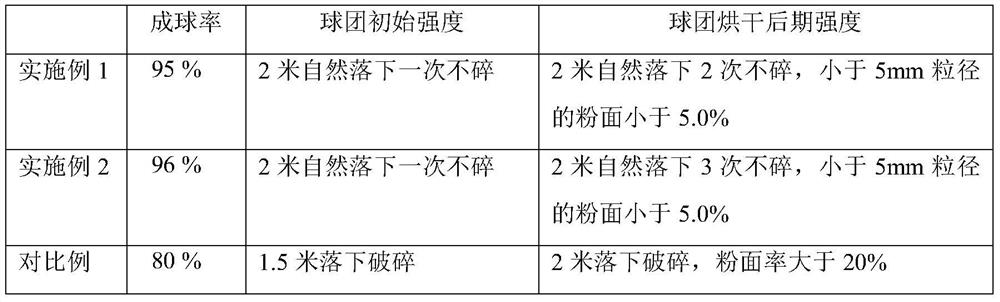

A technology of corundum slag pellets and binders, which is applied in the field of comprehensive utilization and processing of secondary resources, can solve the problem of low (initial strength 1.5m broken, later strength 2m falling broken, product quality can not meet the technical requirements of processing technology, unfavorable Step drying and other issues to achieve the effect of ensuring ball forming performance, reducing drying costs, and improving viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Special binder for corundum slag pellets in this embodiment: the raw materials are: 66% of plant starch, 5% of polymer polyanion cellulose, 16% of plant dextrin, and 13% of sodium fluorosilicate.

[0022] The preparation method of the special binder for corundum slag pellets in this embodiment: add the raw materials in a closed mixing and milling equipment in order of weight ratio from high to low, and grind them evenly.

[0023] The method of using the special binder for corundum slag pellets in this embodiment: add the corundum slag to the mixer and stir for 1 minute, add water with a weight ratio of 8% of the corundum slag and mix for 2 minutes, add 1.5% of the special adhesive for corundum slag pellets The mixture was stirred for 2 minutes, then water with a total weight of 4 was added and stirred for 2 minutes to obtain a mixture, which was extruded into balls.

Embodiment 2

[0025] Special binder for corundum slag pellets in this embodiment: the raw materials are calculated by weight percentage: 68% of plant starch, 4% of polymer polyanion cellulose, 17% of plant dextrin, and 11% of sodium carbonate.

[0026] The preparation method of the special binder for corundum slag pellets in this embodiment: add the raw materials in a closed mixing and milling equipment in order of weight ratio from high to low, and grind them evenly.

[0027] The method of using the special binder for corundum slag pellets in this example: add the corundum slag to the mixer and stir for 1 minute, add water with a weight ratio of 9% of the corundum slag and mix for 2 minutes, add 2.0% of the special adhesive for corundum slag pellets The mixture was stirred for 2 minutes, then water with a total weight of 4 was added and stirred for 2 minutes to obtain a mixture, which was extruded into balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com