Preparation technology of spherical chromium oxide composite agglomerated powder, and product prepared by preparation process

A preparation process and technology of chromium oxide, applied in the direction of chromium oxide/hydrate, coating, etc., can solve the problems affecting the comprehensive performance of chromium oxide coating, segregation of chromium oxide coating, uneven distribution of chemical components, etc. Guaranteed sphericity and compactness, inhibiting valence changes, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation process of spherical chromium oxide composite agglomerated powder comprises the following steps:

[0045] (1), Dissolve chromium nitrate in deionized water, then add SiO in the solution 2 Nano powder and TiO 2 Nano powder (wherein, the concentration of chromium nitrate solution is 2mol / L, SiO 2 、TiO 2 The mass ratio of chromium nitrate and chromium nitrate is 4.5:3:289.7), ultrasonic treatment, to obtain a mixed solution; add ammonia water drop by drop to the mixed solution, adjust the pH value of the solution to 9, and obtain SiO 2 Nano powder and TiO 2 Nano-powder is the coated precursor of the core, filtered and dried to obtain a solid product;

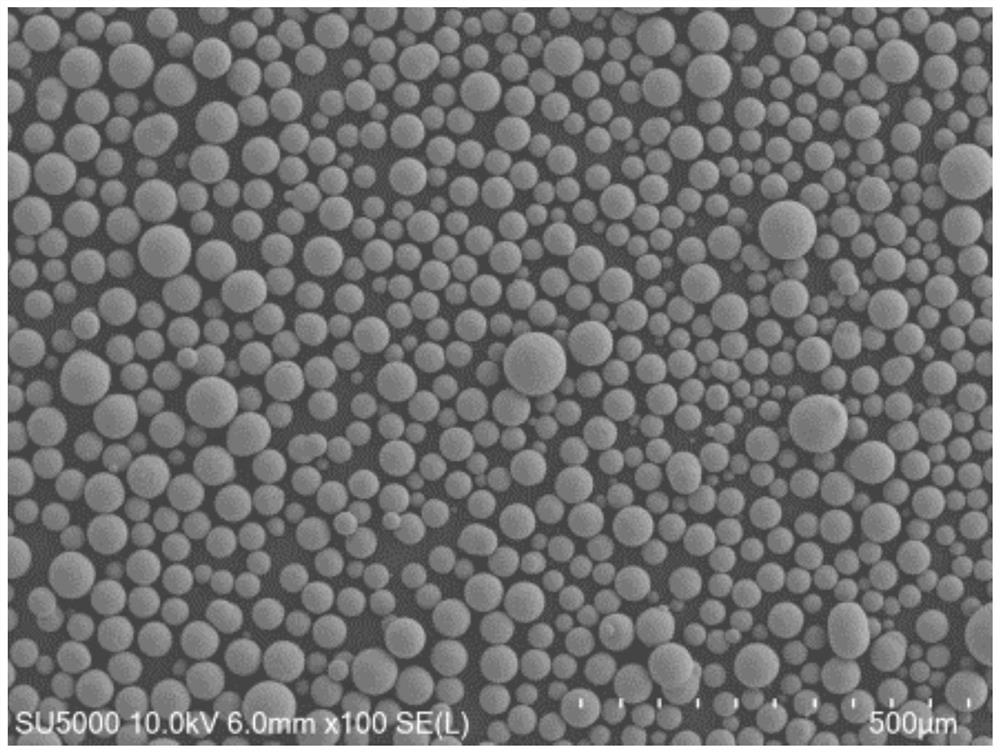

[0046] (2), the solid product prepared in step (1) and the polystyrene accounting for 15% of the solid product weight are formulated with deionized water into a slurry with a solid content of 55%, and the configured slurry is sprayed into granulation Tower, through spray granulation combined with atmospher...

Embodiment 2

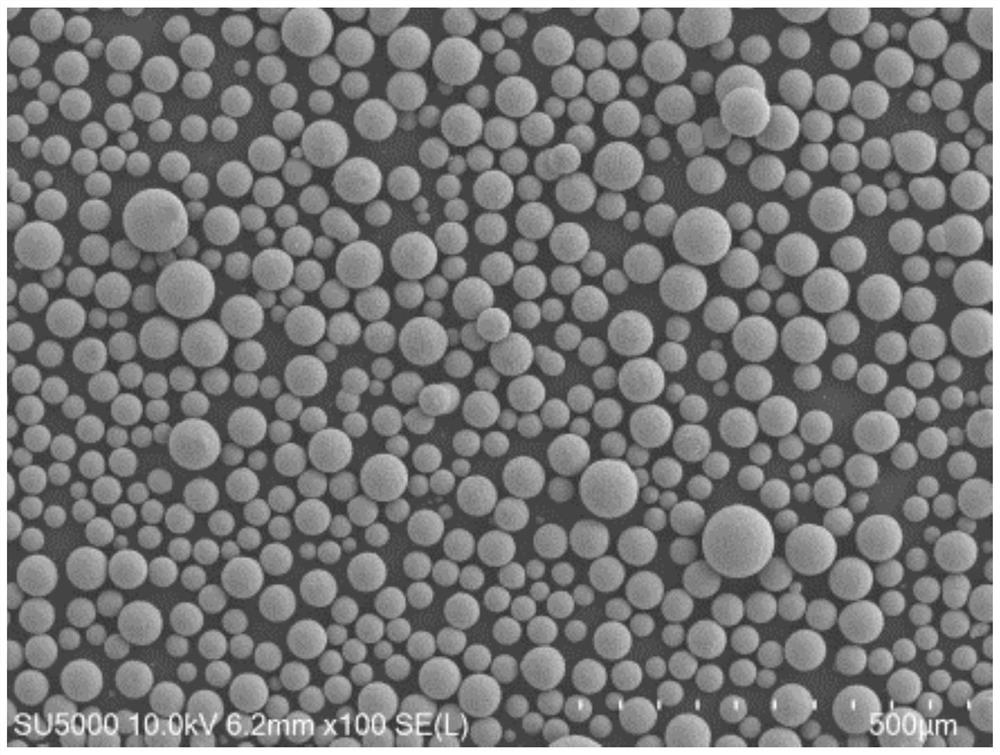

[0048] The difference between embodiment 2 and embodiment 1 is: in embodiment 2, the concentration of chromium nitrate solution is 1mol / L, SiO 2 、TiO 2 The mass ratio of chromium nitrate and chromium nitrate is 3:4:285, the pH value is adjusted to 8 after adding ammonia water dropwise, the solid content of the slurry is 50%, and the rest are consistent with Example 1.

Embodiment 3

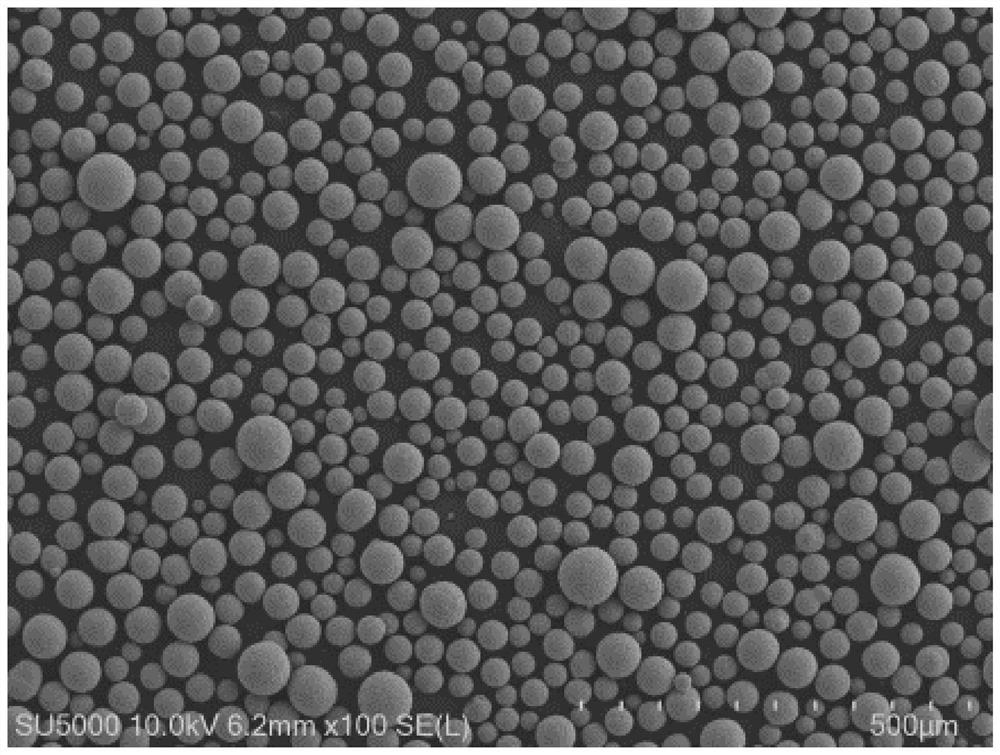

[0050] The difference between embodiment 3 and embodiment 1 is: in embodiment 3, the concentration of chromium nitrate solution is 3mol / L, SiO 2 、TiO 2 The mass ratio to chromium nitrate is 5:2:297.5, the pH value is adjusted to 11 after adding ammonia water dropwise, the solid content of the slurry is 60%, and the rest are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com