A kind of preparation method of titanium-doped lithium iron phosphate cathode material

A technology for lithium iron phosphate and positive electrode materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., and can solve the problems of low specific capacitance and tap density, low electrical conductivity, low tap density, and preparation process of lithium iron phosphate positive electrode materials. Complicated problems, to achieve the effect of good consistency, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

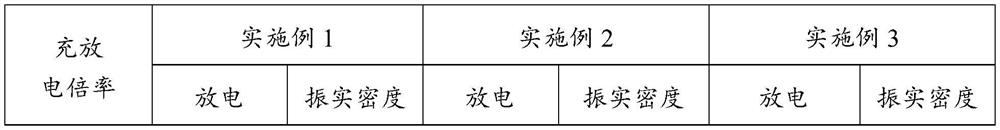

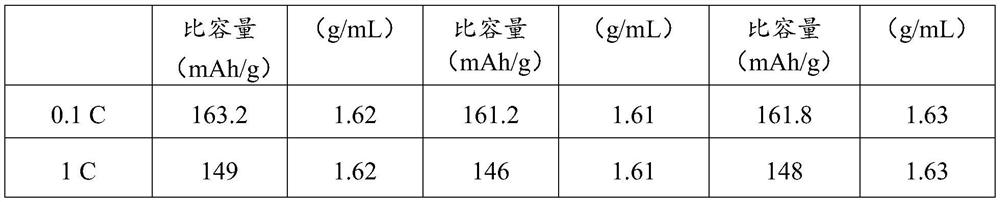

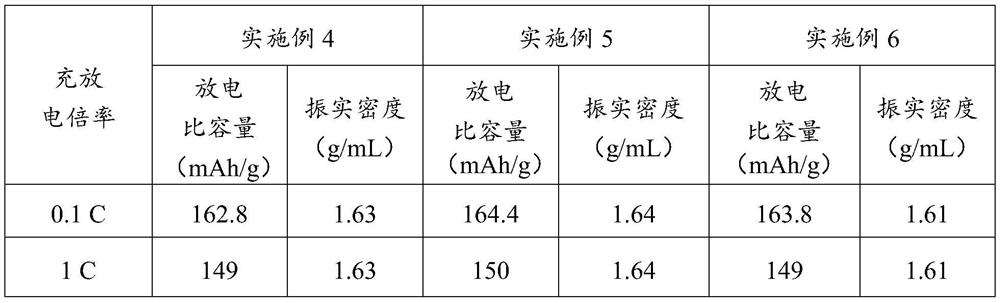

Embodiment 1

[0031] A method for preparing a titanium-doped lithium iron phosphate cathode material, characterized in that it comprises the following steps:

[0032] (1) Get raw materials: get lithium carbonate 24.8g, ferric oxide 44.39g, ammonium dihydrogen phosphate 73.93g, metal titanium powder 2.4g;

[0033] (2) heating and melting: the raw materials are mixed evenly, put into a crucible, put into a melting furnace, and heat and melt to a glass state at a certain temperature;

[0034] (3) Water quenching: adding the mixture melted to a glass state into purified water with a water temperature of 30° C., performing water quenching, and filtering the obtained semi-finished lithium iron phosphate positive electrode material;

[0035] (4) Grinding and dispersing: take 0.10 times the glucose of the semi-finished lithium iron phosphate positive electrode material on a dry basis, add it to the semi-finished lithium iron phosphate positive electrode material, and the quality of the added purifi...

Embodiment 2

[0041] A method for preparing a titanium-doped lithium iron phosphate cathode material, characterized in that it comprises the following steps:

[0042] (1) Get raw materials: get lithium carbonate 24.8g, ferric oxide 43.42g, ammonium dihydrogen phosphate 73.93g, metal titanium powder 3g;

[0043] (2) heating and melting: the raw materials are mixed evenly, put into a crucible, put into a melting furnace, and heat and melt to a glass state at a certain temperature;

[0044] (3) Water quenching: adding the mixture melted to a glass state into purified water with a water temperature of 30° C., performing water quenching, and filtering the obtained semi-finished lithium iron phosphate positive electrode material;

[0045] (4) Grinding and dispersion: take 0.11 times the glucose of the semi-finished lithium iron phosphate positive electrode material on a dry basis, add it to the semi-finished lithium iron phosphate positive electrode material, and the quality of the added purified...

Embodiment 3

[0051] A method for preparing a titanium-doped lithium iron phosphate cathode material, characterized in that it comprises the following steps:

[0052] (1) Get raw materials: lithium carbonate 24.8g, ferric oxide 41.39g, ammonium dihydrogen phosphate 73.93g, metal titanium powder 4.2g;

[0053] (2) heating and melting: the raw materials are mixed evenly, put into a crucible, put into a melting furnace, and heat and melt to a glass state at a certain temperature;

[0054] (3) Water quenching: adding the mixture melted to a glass state into purified water with a water temperature of 30° C., performing water quenching, and filtering the obtained semi-finished lithium iron phosphate positive electrode material;

[0055] (4) Grinding and dispersion: take 0.12 times the glucose of the semi-finished lithium iron phosphate positive electrode material on a dry basis, and add it to the semi-finished lithium iron phosphate positive electrode material, and the quality of the added purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com