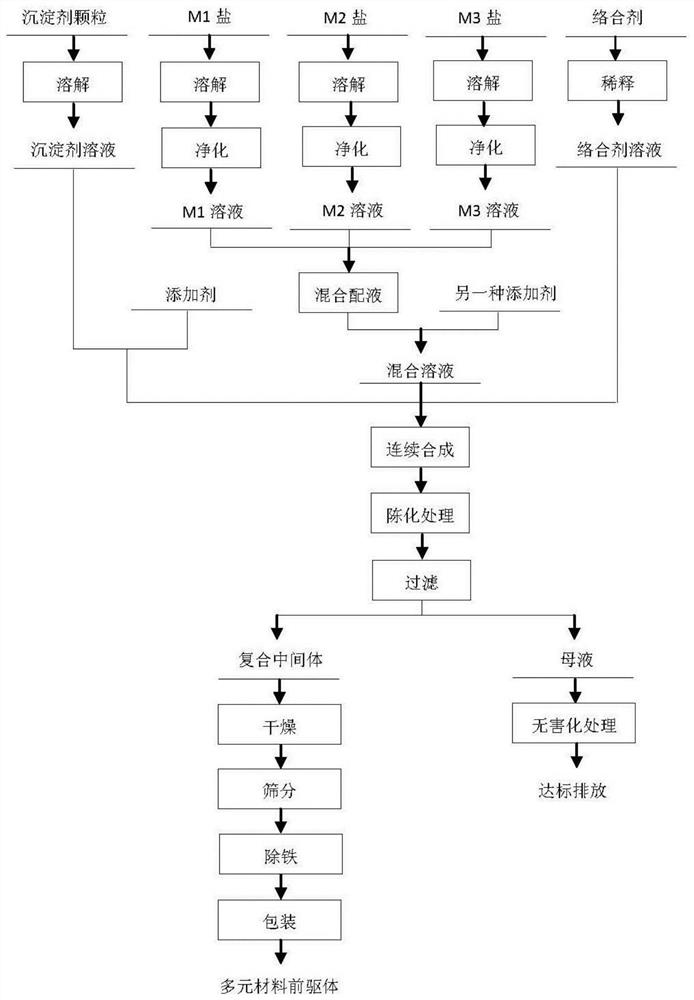

Synthesis of high-dispersion multi-element precursor

A high-dispersion, precursor technology, applied in electrical components, nickel compounds, inorganic chemistry, etc., can solve problems such as inability to meet product performance requirements, and achieve improved overall product quality, high consistency of particle morphology, and sphericity. The effect of accelerated crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

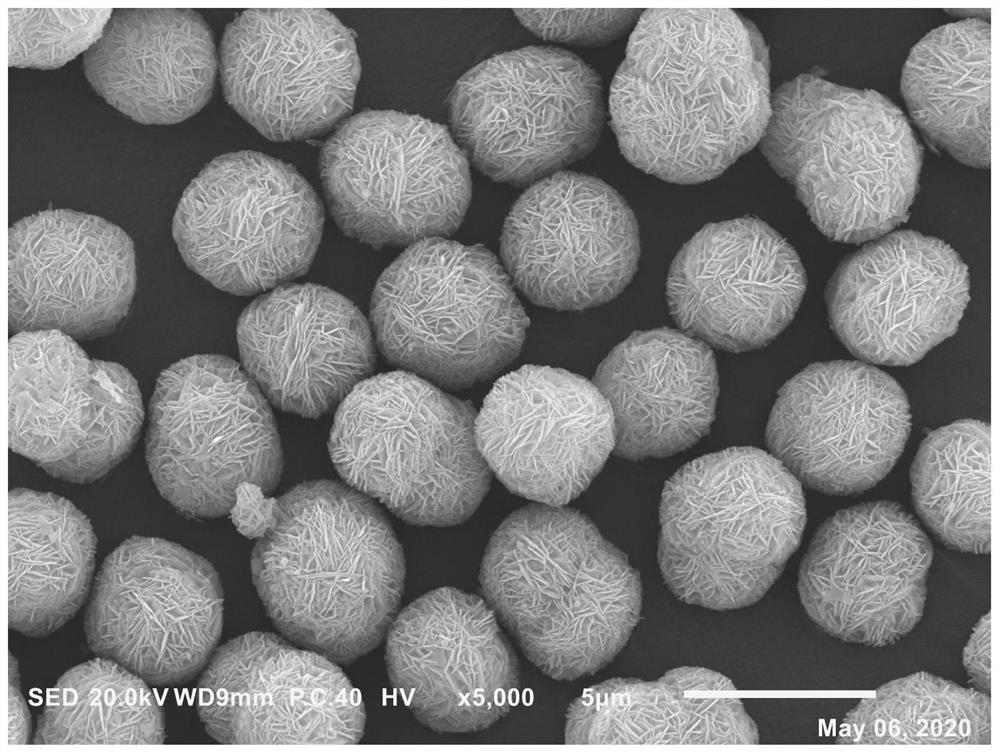

Embodiment 1

[0028] Synthesis of multiple precursors is carried out as follows:

[0029] (1) Nickel sulfate, cobalt sulfate, manganese sulfate are formulated into the metal mixed salt solution that metal ion concentration is 2M by the ratio of Ni:Co:Mn=55:05:40 with deionized water, then add SDS (dodecane Sodium base sulfate) makes the concentration of SDS in the solution be 0.02M;

[0030] (2) Sodium hydroxide is prepared into a solution with a concentration of 10M with deionized water, and CTAB (cetyltrimethylammonium bromide) is added so that the concentration of CTAB in the solution is 0.05M;

[0031] (3) Dilute the aqueous ammonia solution to a concentration of 10M;

[0032] (4) Open the reaction kettle, add 30L of bottom liquid, turn on the stirring, the stirring speed is 500rpm, turn on the mold temperature controller connected to the jacket of the reaction kettle, heat the solution in the reaction kettle to 60°C, and keep it constant. The nitrogen flow rate of 2L / min was passed i...

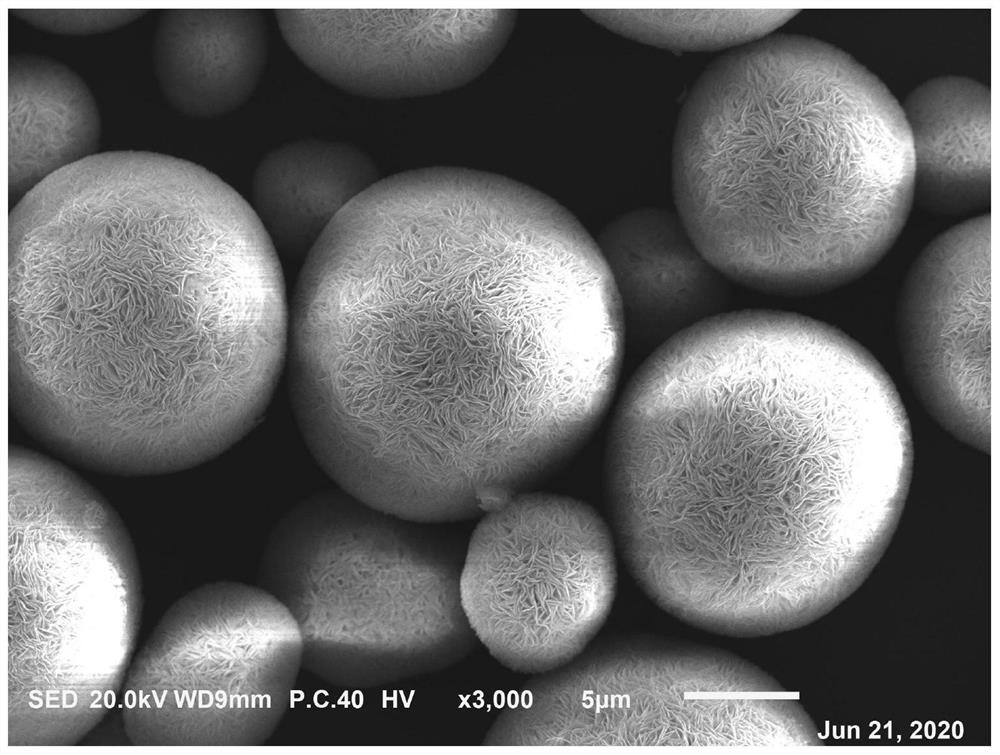

Embodiment 2

[0035] Synthesis of multiple precursors is carried out as follows:

[0036] (1) Nickel sulfate, cobalt sulfate, manganese sulfate are formulated into the metal mixed salt solution that metal ion concentration is 2M by Ni:Co:Mn=83:11:06 with deionized water, then add SDS (dodecylsulfuric acid Sodium) makes the concentration of SDS in the solution be 0.02M;

[0037] (2) Sodium hydroxide is prepared into a solution with a concentration of 10M with deionized water, and CTAB (cetyltrimethylammonium bromide) is added so that the concentration of CTAB in the solution is 0.05M;

[0038] (3) Dilute the aqueous ammonia solution to a concentration of 10M;

[0039](4) Connect the three reaction kettles in series in sequence, open the first reaction kettle, add 30L bottom liquid, turn on the stirring, the stirring speed is 500rpm, open the mold temperature controller connected to the jacket of the reaction kettle, heat the solution in the reaction kettle to 60°C, and keep it constant. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com