A kind of denitrification catalyst and preparation method thereof

A technology of denitrification catalyst and palladium oxide, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy poisoning and low denitrification rate, prolong service life, reduce SO2 concentration, Aggregation-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

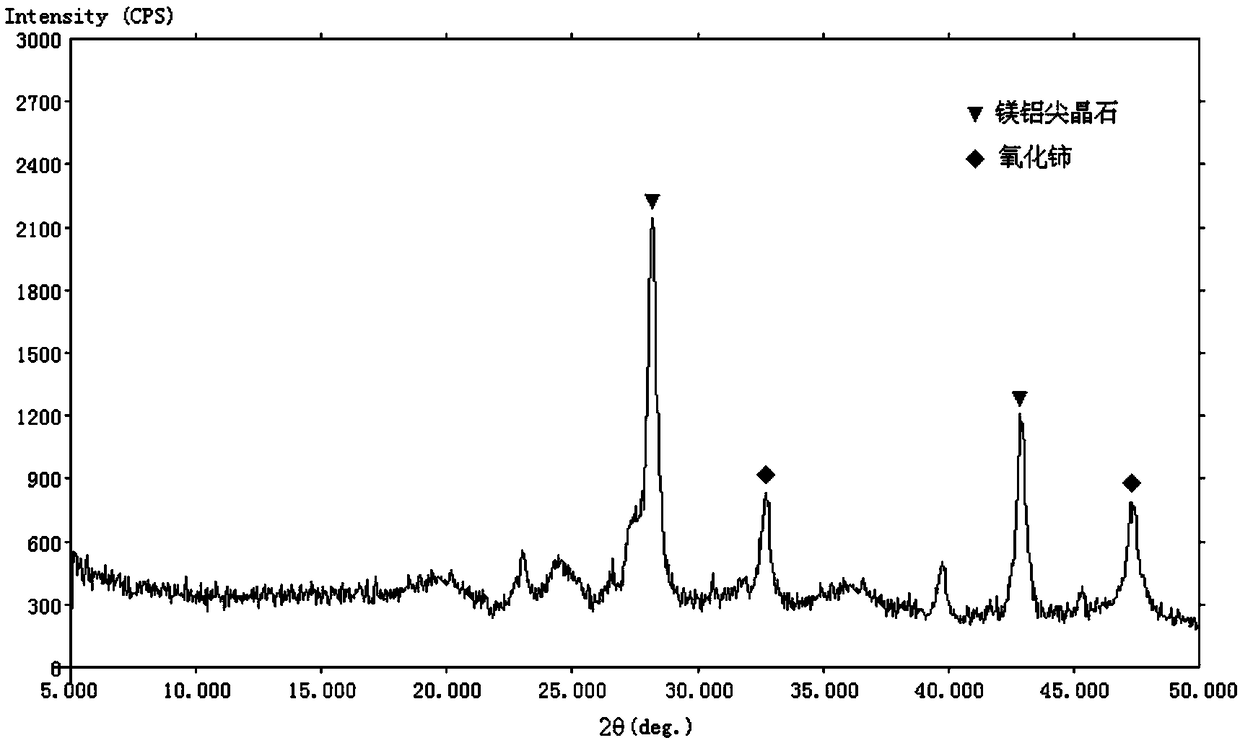

Image

Examples

Embodiment 1

[0038] The preparation method of the denitration catalyst described in this embodiment comprises the following steps:

[0039] (1) Add 200g of deionized water and 90g of activated alumina in a beaker equipped with a stirrer, stir, add 175g of aqueous solution containing 38wt% hydrochloric acid after mixing, and continue to stir until a uniform sol is formed;

[0040] Add 55g of heavy magnesium oxide and 80g of deionized water into another beaker equipped with a stirrer, stir evenly, transfer to the above-mentioned sol, and continue stirring for 2 hours to obtain the first slurry;

[0041] Mix 24g of cerium chloride with 50g of deionized water, stir until the solution is transparent, add ammonia water dropwise to adjust the pH value of the solution to 7, obtain a cerium-containing aqueous solution, and then transfer it to the above-mentioned first slurry to form a second slurry, Stir the second slurry at a constant temperature of 60°C, spray dry the second slurry after 5 hours,...

Embodiment 2

[0045] The preparation method of the denitration catalyst described in this embodiment comprises the following steps:

[0046] (1) Add 148g deionized water and 68g SB powder in a beaker equipped with a stirrer, stir, add 80g of aqueous solution containing 30wt% sulfuric acid after mixing, continue stirring until a uniform sol is formed;

[0047] Add 48g of activated magnesium oxide and 70g of deionized water to another beaker equipped with a stirrer, stir evenly, transfer to the above-mentioned sol, and continue stirring for 4 hours to obtain the first slurry;

[0048] Mix 6.5g of lanthanum nitrate with 10g of deionized water, stir until the solution is transparent, add ammonia water dropwise to adjust the pH value of the solution to 7, obtain an aqueous solution containing lanthanum, and then transfer it to the above-mentioned first slurry to form the second slurry, Stir the second slurry at a constant temperature of 70°C, spray dry the second slurry after 4 hours, and roast ...

Embodiment 3

[0053] The preparation method of the denitration catalyst described in this embodiment comprises the following steps:

[0054] (1) Add 170g deionized water and 74g pseudo-boehmite to a beaker equipped with a stirrer, stir, add 185g of an aqueous solution containing 25wt% nitric acid after mixing, and continue stirring until a uniform sol is formed;

[0055] Add 37g of light magnesium oxide and 50g of deionized water into another beaker equipped with a stirrer, stir evenly, transfer to the above-mentioned sol, and continue stirring for 3 hours to obtain the first slurry;

[0056] Mix 23g of cerium nitrate with 63g of deionized water, stir until the solution is transparent, then add ammonia water dropwise to adjust the pH value of the solution to 7 to obtain a cerium-containing aqueous solution, then transfer it to the above-mentioned first slurry to form the second slurry, and keep the temperature constant stirring the second slurry at 65°C, spray-drying the second slurry after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com