Method for improving strength of catalytic cracking propylene assistant and application

A propylene additive and catalytic cracking technology, which is applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of incompatibility between wear index and particle size distribution, and achieve good industrial production, catalytic activity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

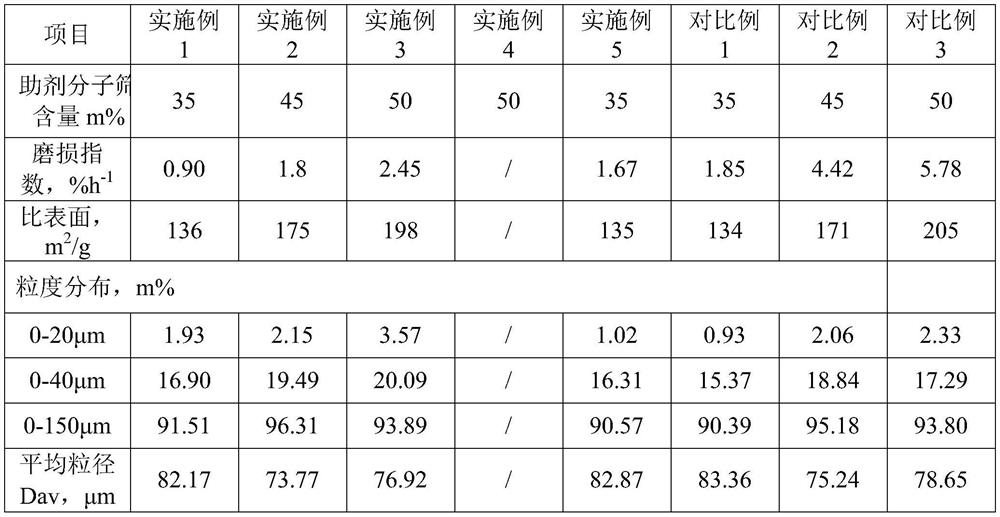

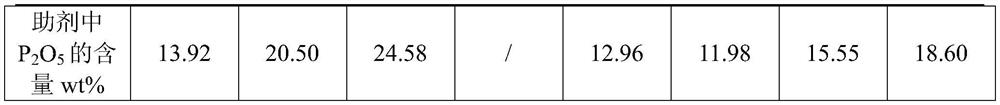

Embodiment 1

[0041] Take 100 g of the propylene additive prepared in Comparative Example 1, add 100 g of purified water, add 7.15 g of the prepared aluminum phosphate solution under stirring, stir for 30 min, and filter to obtain a filter cake with a solid content of 50%, P 2 o 5 The load is 2%, calcined at 600°C for 2 hours, washed with water 5 times as much as the additive, filtered the filter cake, and dried at 110°C to obtain the modified propylene additive.

Embodiment 2

[0043] Take 100 g of the propylene additive prepared in Comparative Example 2, add 100 g of purified water, add 20 g of the prepared aluminum phosphate solution under stirring, stir for 30 min, and filter to obtain a filter cake with a solid content of 50%, P 2 o 5 The load is 5%, calcined at 750°C for 1 hour, washed with water 5 times as much as the additive, filtered the filter cake, and dried at 120°C to obtain the modified propylene additive.

Embodiment 3

[0045] Take 100 g of the propylene additive prepared in Comparative Example 3, add 100 g of purified water, add 36.37 g of the aluminum phosphate solution prepared in Preparation Example 1 under stirring, stir for 30 min, and filter to obtain a filter cake with a solid content of 50%, P 2 o 5 The load is 8%, calcined at 550°C for 4 hours, washed with water 5 times as much as the additive, filtered the filter cake, and dried at 115°C to obtain the modified propylene additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com