Recovery method of microspherical catalyst of fluid bed

A technology of catalyst and fluidized bed, which is applied in the recovery field of microsphere catalyst for fluidized bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] It is 30wt% to calculate by oxide dry base solid content in feed liquid, the silica sol (content 30wt%) of metering, aluminum sol (content 20%), calcium nitrate (content 23%), kaolin (content 85wt%) and SAPO The former powder of -34 molecular sieve was added into a certain amount of deionized water in sequence, and stirred for 30 minutes (the oxide dry basis mass content of each raw material was respectively 25%, 10%, 5%, 30%, and 30%) in sequence, and finally added Squash powder (soaked with a small amount of ethanol) equivalent to 0.5% of the dry weight of the total oxides, stirred for 30 minutes. The feed liquid is passed through a colloid mill for colloid milling, so that 70% of the particle diameters in the finally obtained slurry are less than 5 μm. After the slurry was left at room temperature for 2 hours, it was subjected to centrifugal spray drying, the atomizer rotated at 30 Hz, the inlet temperature was 400°C, and the outlet temperature was not lower than 120...

Embodiment 2

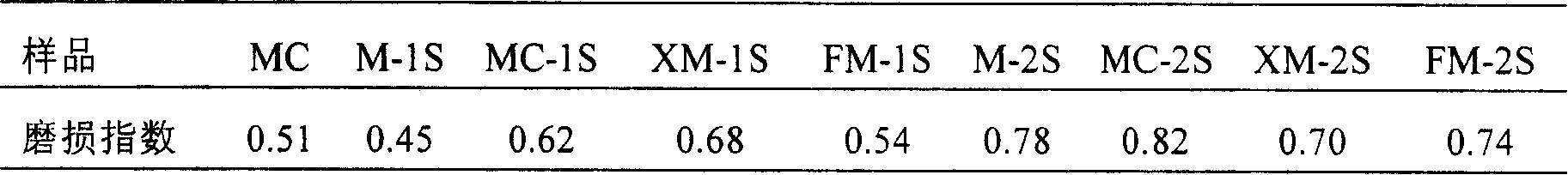

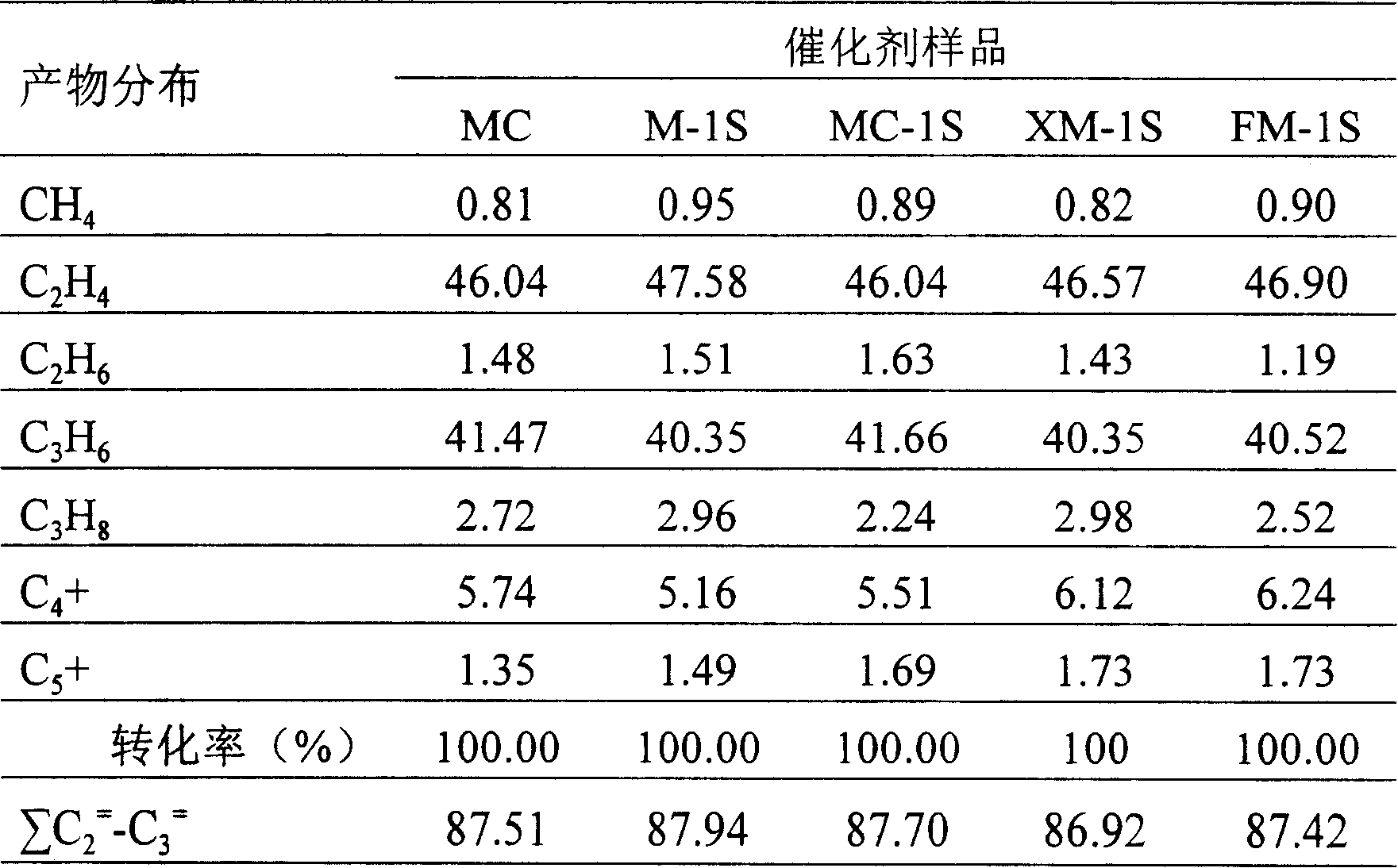

[0023] The MC sample obtained in Example 1 was used in a circulating fluidized bed (catalyst loading capacity of 4 tons, methanol processing capacity of 50 tons / day) in an industrial test to carry out methanol conversion to olefins reaction. After 30 days of stable operation of the device, the collected catalyst powder was taken out from the sampling port of the cyclone separator, and recorded as XM. A small amount of catalyst sample was taken from the sampling port of the reactor, denoted as FM.

Embodiment 3

[0025] Some samples of XM and FM were taken and calcined in air at 650°C to remove the moisture and reaction carbon residue contained therein, and the obtained samples were denoted as XMC and FMC respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com