Preparation method and application of catalyst

A technology for catalysts and hydrogenation catalysts, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as time-consuming, difficult to analyze results, cumbersome and complicated operation steps, etc., achieve fast speed and low wear index , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

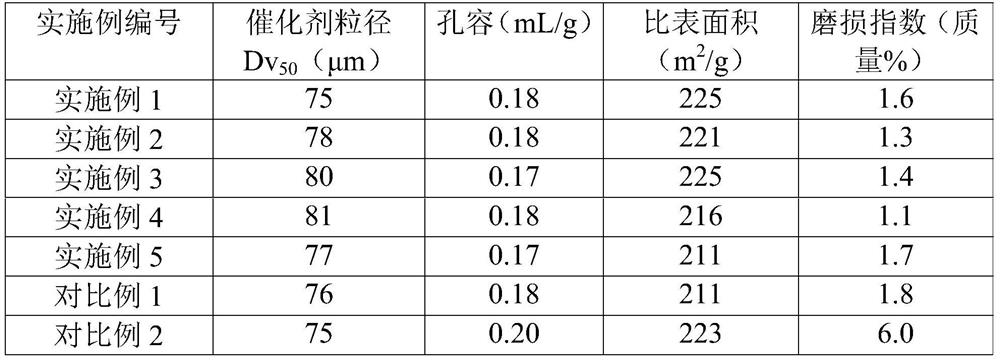

Examples

preparation example Construction

[0024] A first aspect of the present invention provides a method for preparing a catalyst, the method comprising the following steps:

[0025] 1) the step of preparing an alumina suspension with the pseudo-boehmite sample to be tested and water;

[0026] 2) the step of mixing the aluminum oxide suspension obtained in step 1) with an acid to obtain a glue solution;

[0027] 3) the step of measuring the particle size of the mixed solution obtained in step 2);

[0028] Wherein, when step 3) measures particle size Dv 90 When ≤15 μm, peptization of pseudo-boehmite is used to prepare the catalyst.

[0029] The inventors of the present invention have found through a large number of studies that there is a corresponding relationship between the peptization performance of pseudo-boehmite and the particle size, when Dv 90 When the diameter is less than or equal to 15 μm, the pseudo-boehmite has good peptization performance and is suitable for preparing catalysts. According to the pr...

Embodiment 1

[0045] (1) Take 16.21g of pseudo-boehmite and add 83.5g of deionized water, and mix to obtain alumina suspension.

[0046] (2) Add 3.00 g of 20% by mass hydrochloric acid to the alumina suspension to make the acidic H + The molar ratio to the aluminum oxide suspension in terms of Al element was 0.09:1, and the mixture was stirred at a stirring speed of 500 rpm for 15 minutes to obtain a glue solution.

[0047] (3) Get 5mL of glue solution from the glue solution that keeps stirring at 500rpm, add dropwise in the sample container of laser particle size analyzer (manufactured by Malvern, model is MS3000), record particle diameter Dv 90 = 9.23 μm.

[0048] (4) Catalyst preparation: pseudo-boehmite: kaolin: molecular sieve: aluminum sol is mixed in a mass ratio of 20:40:30:10, and then water is added so that the solid content in the mixed solution is 35% by mass, mixed evenly, and then hydrochloric acid is added (the mass ratio of hydrochloric acid and pseudo-boehmite is 0.08) ar...

Embodiment 2-5

[0050] Prepare the catalyst according to the method of Example 1, the difference is that the H in the acid is added + With the molar ratio of said alumina suspension in terms of Al element and the Dv of pseudo-boehmite colloidal solution 90 for the values shown in Table 1

[0051] Table 1

[0052] Example number h + Molar ratio with Al

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com