Semi-synthesized olefins conversion catalyst containing modified nano aluminium oxide

A nano-scale, alumina technology, applied in physical/chemical process catalysts, molecular sieve catalysts, catalytic cracking, etc., can solve problems such as limiting the processing capacity of catalytic cracking units, gasoline selectivity decline, catalyst surface area and activity decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

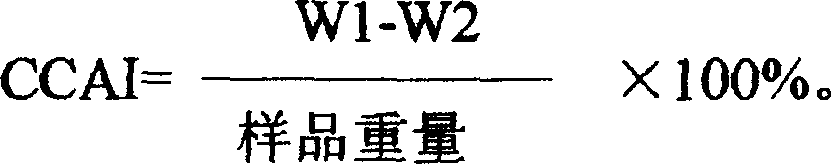

Method used

Image

Examples

example 1

[0023] Add 65L of mixed solution of cerium chloride, zirconium chloride and magnesium chloride to 23529g, n-m alumina. The content of cerium chloride in the solution is 21.5g / l, the concentration of zirconium chloride is 12g / l, and the concentration of magnesium chloride is 142g / l. Soak for 1.5 hours , and then filtered and dried to obtain modified nano-scale alumina A, which contains 4.0% Ce, 2.0% Zr, and 1% Mg.

example 2

[0025] To 23529g n-mAl 2 o 3 Add 65L of a solution containing 42.5g / L of cerium chloride, soak for 1.5 hours, filter, dry, and roast at 400°C for 2 hours, then add 65L of a solution containing 12.8g / l of magnesium sulfate, soak for 1.5 hours, filter, drying. The resulting modified n-mAl 2 o 3 The Ce content in B is 8.0%, and the Mg content is 3.5%.

example 3

[0027] To 23529g n-mAl 2 o 3 Add 80L of a solution containing 42.5g / L of zirconium sulfate solution, soak for 1.5 hours, filter and dry, and the obtained modified nano-alumina C has a Zr content of 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com