Patents

Literature

33results about How to "Inhibition of harmful effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

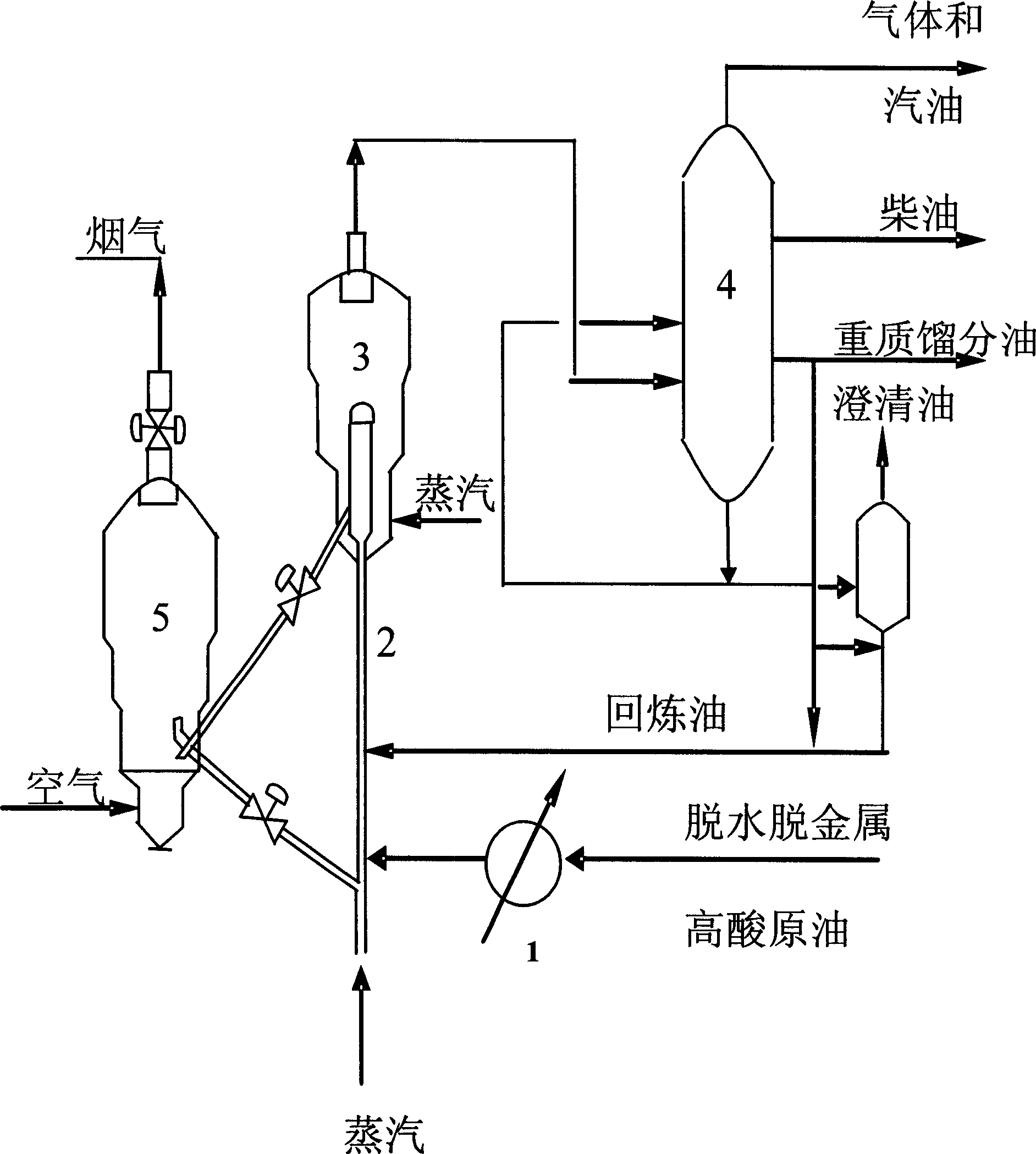

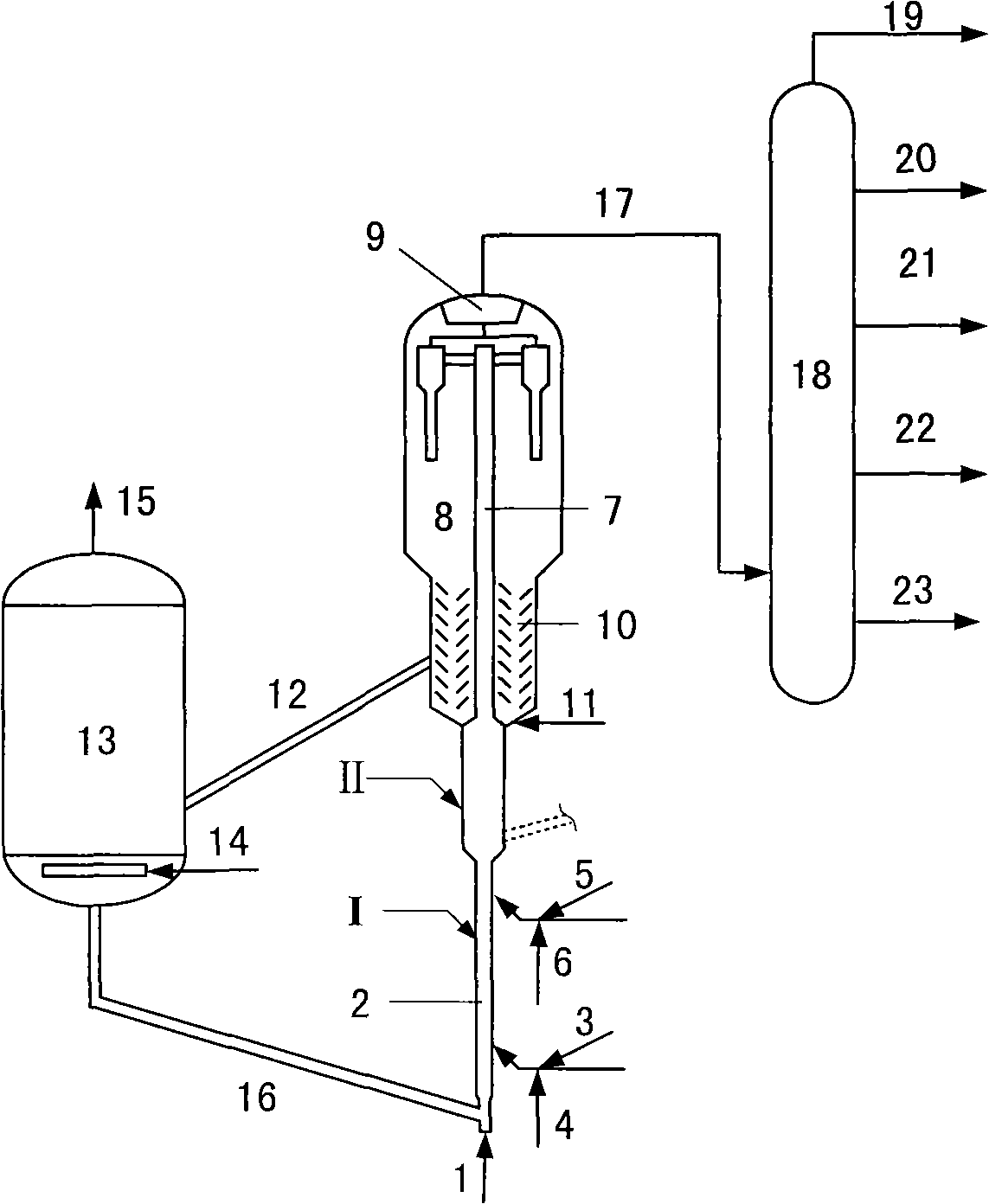

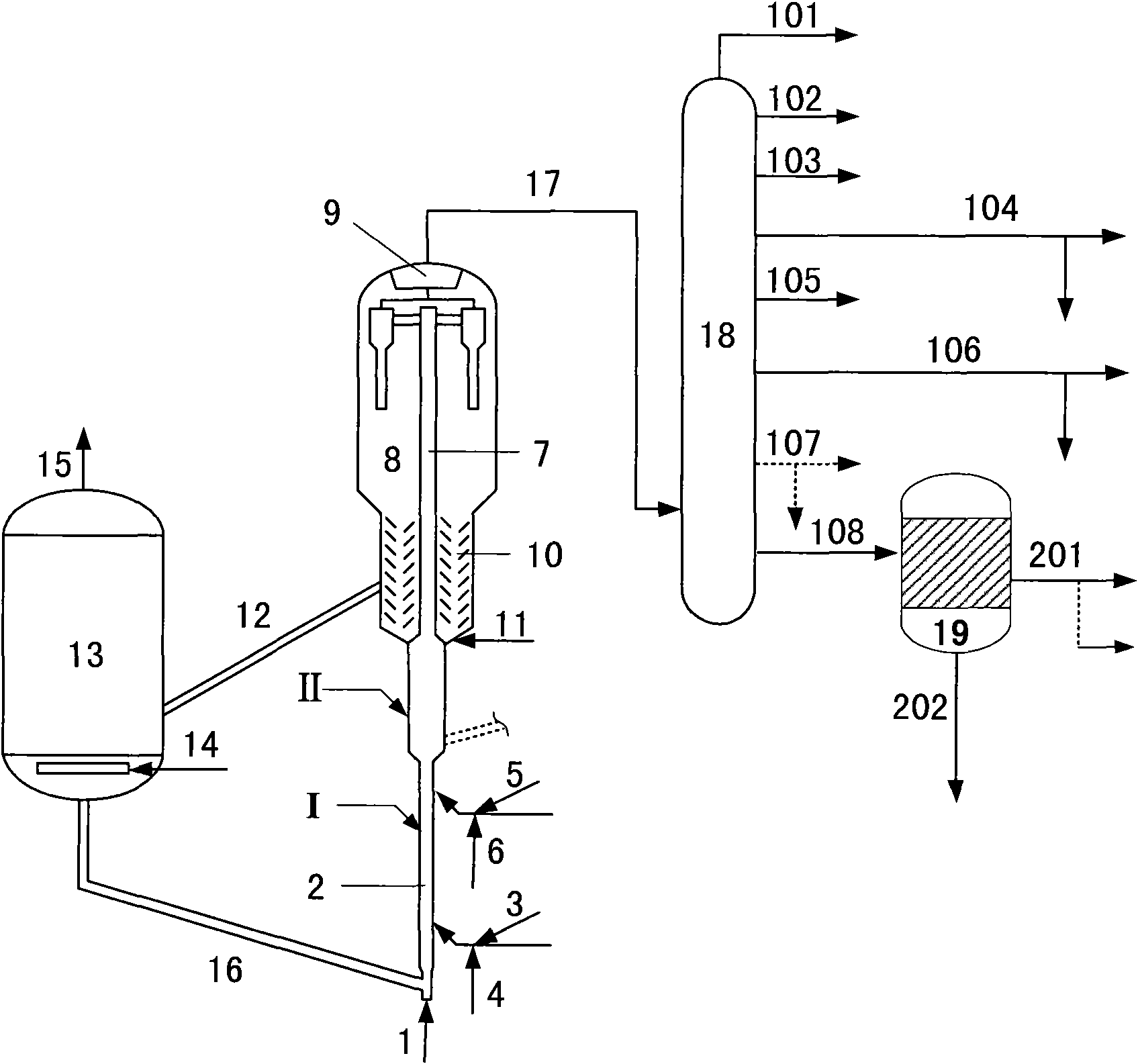

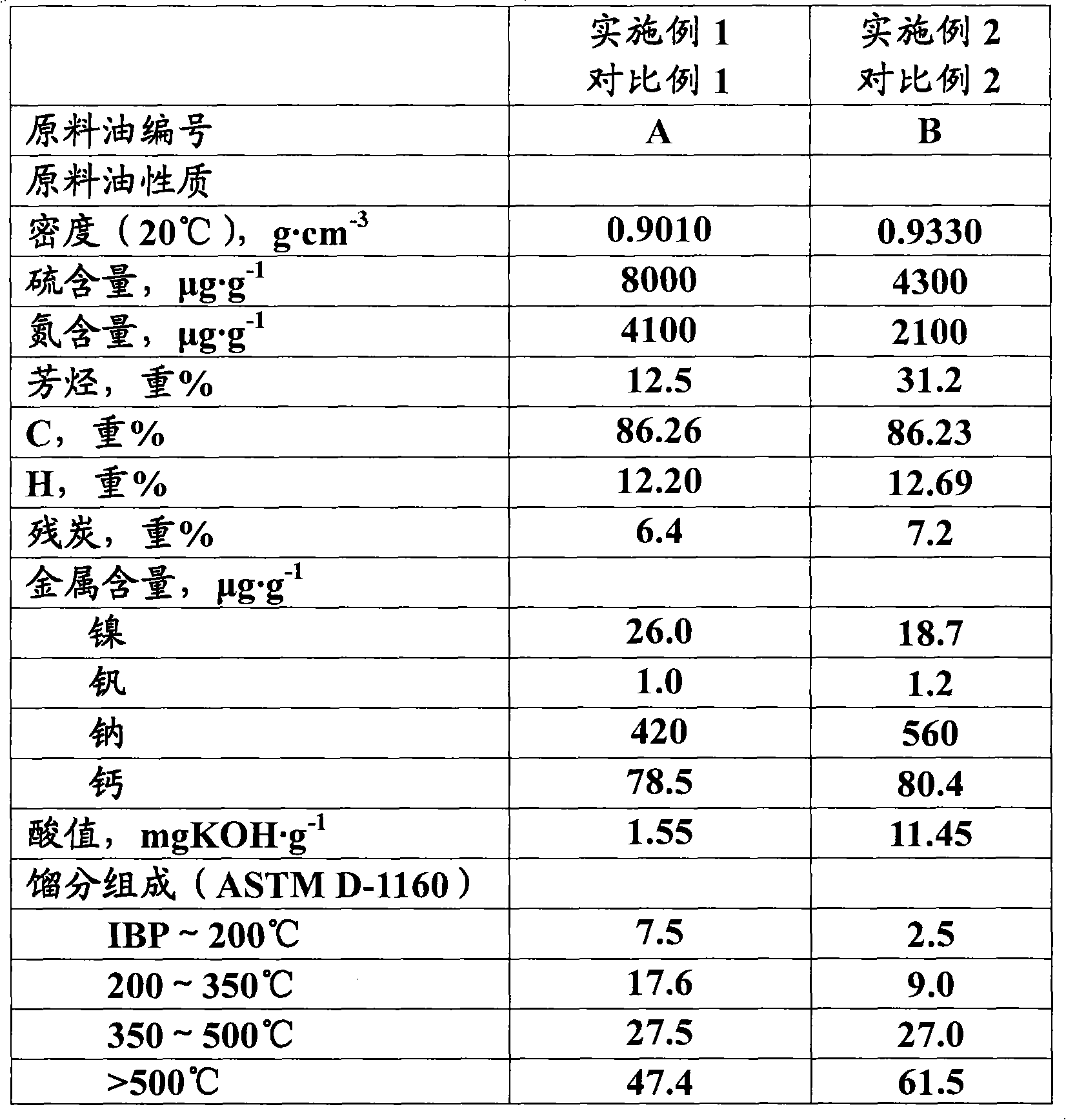

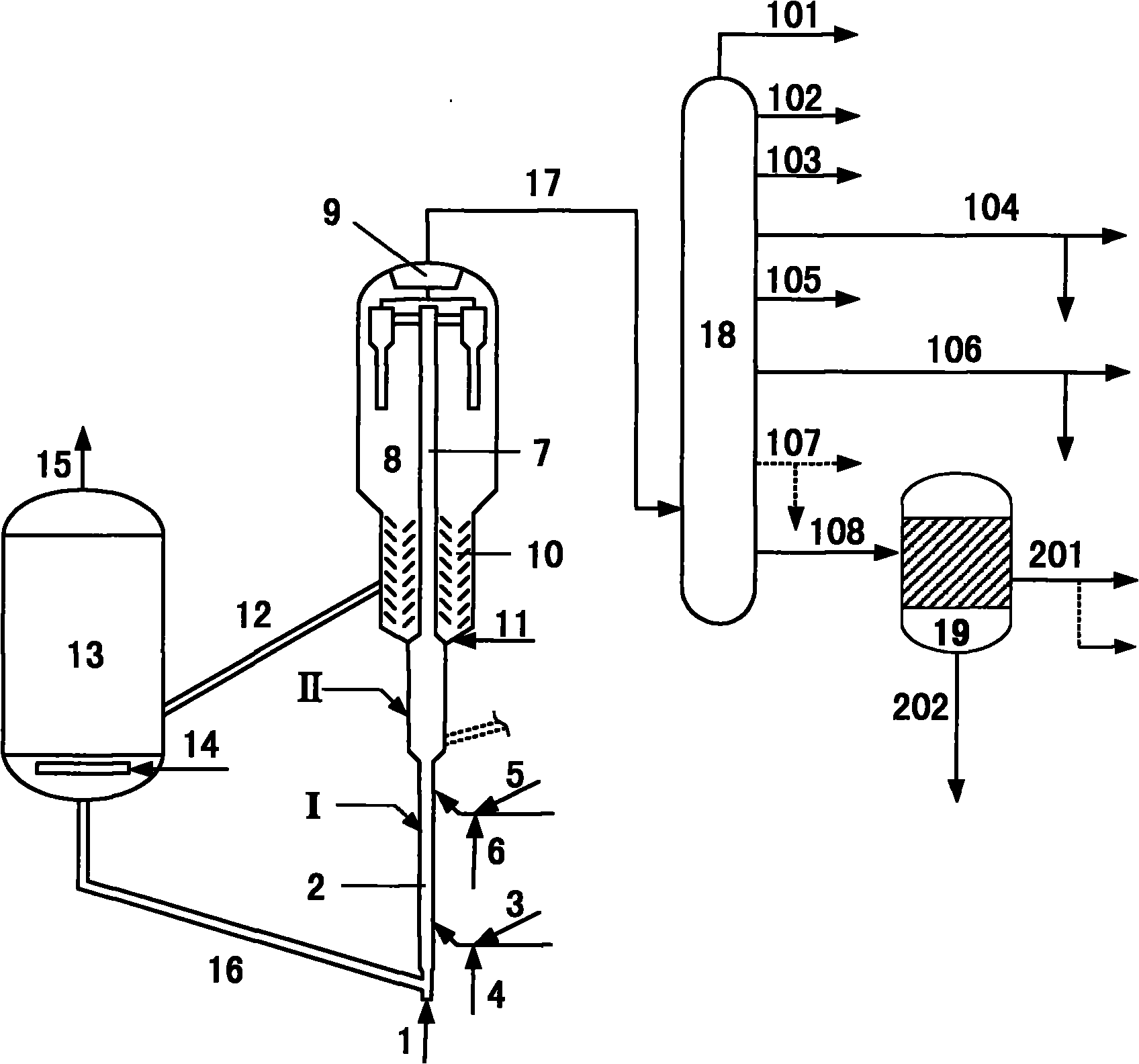

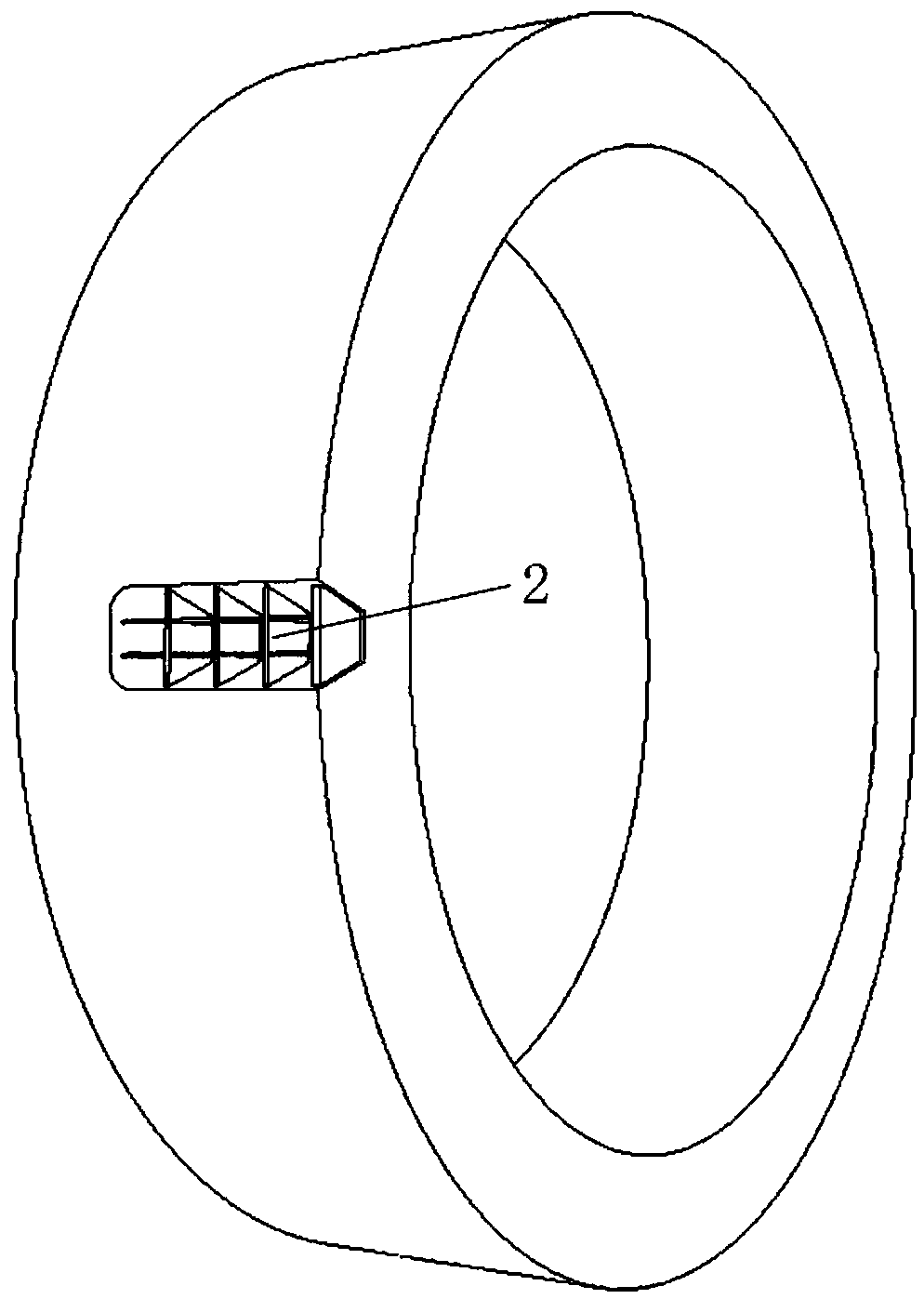

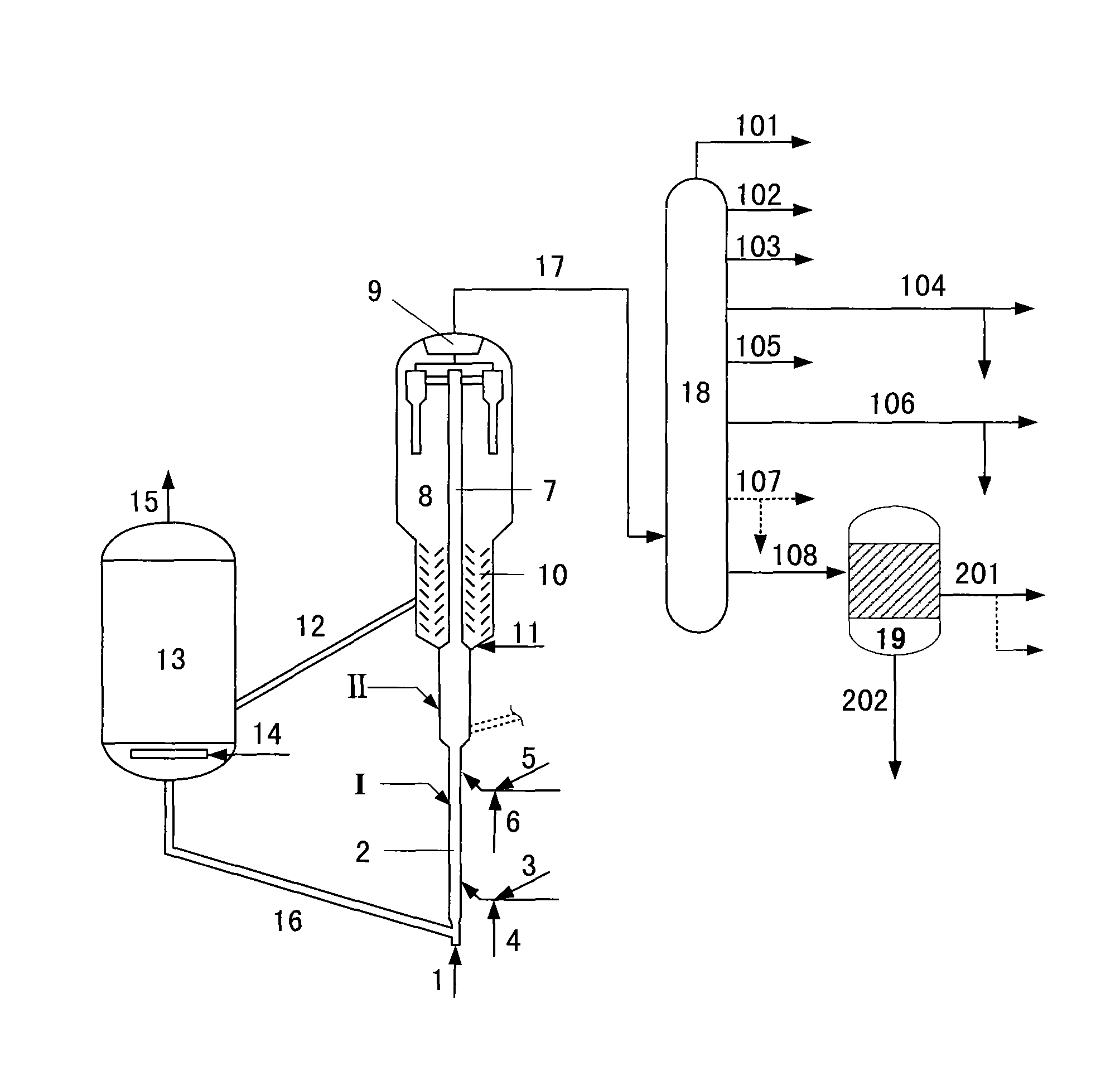

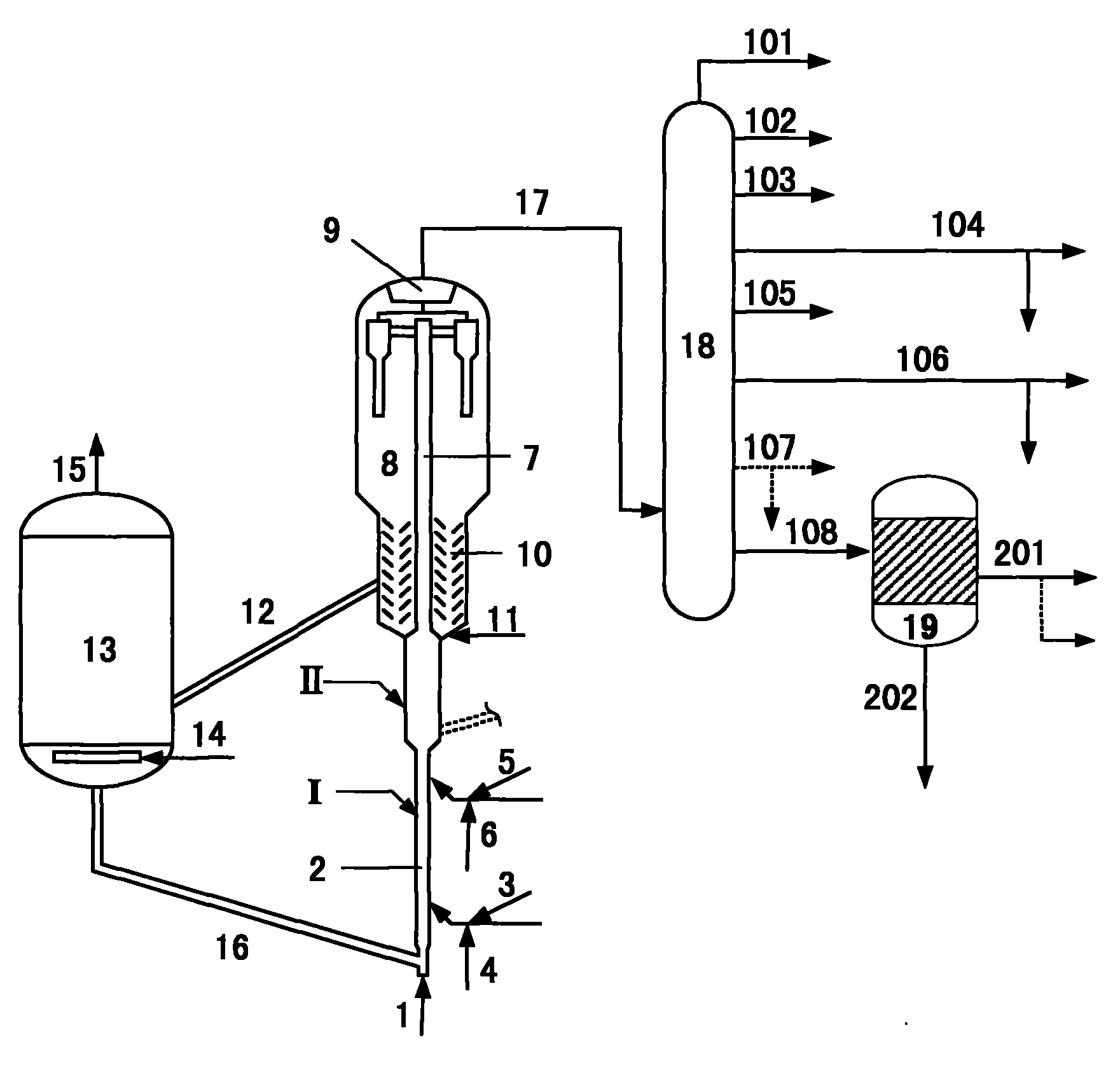

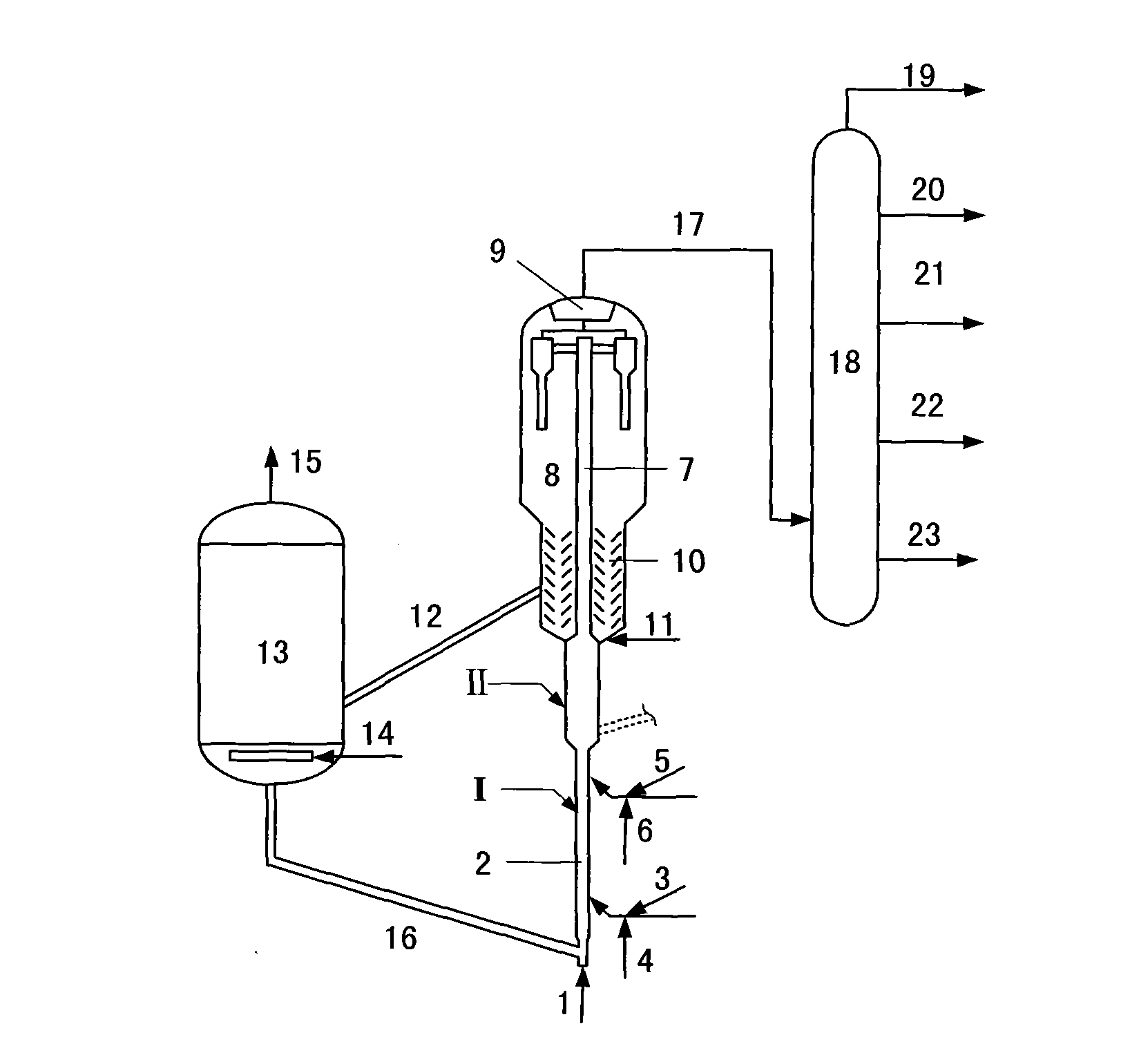

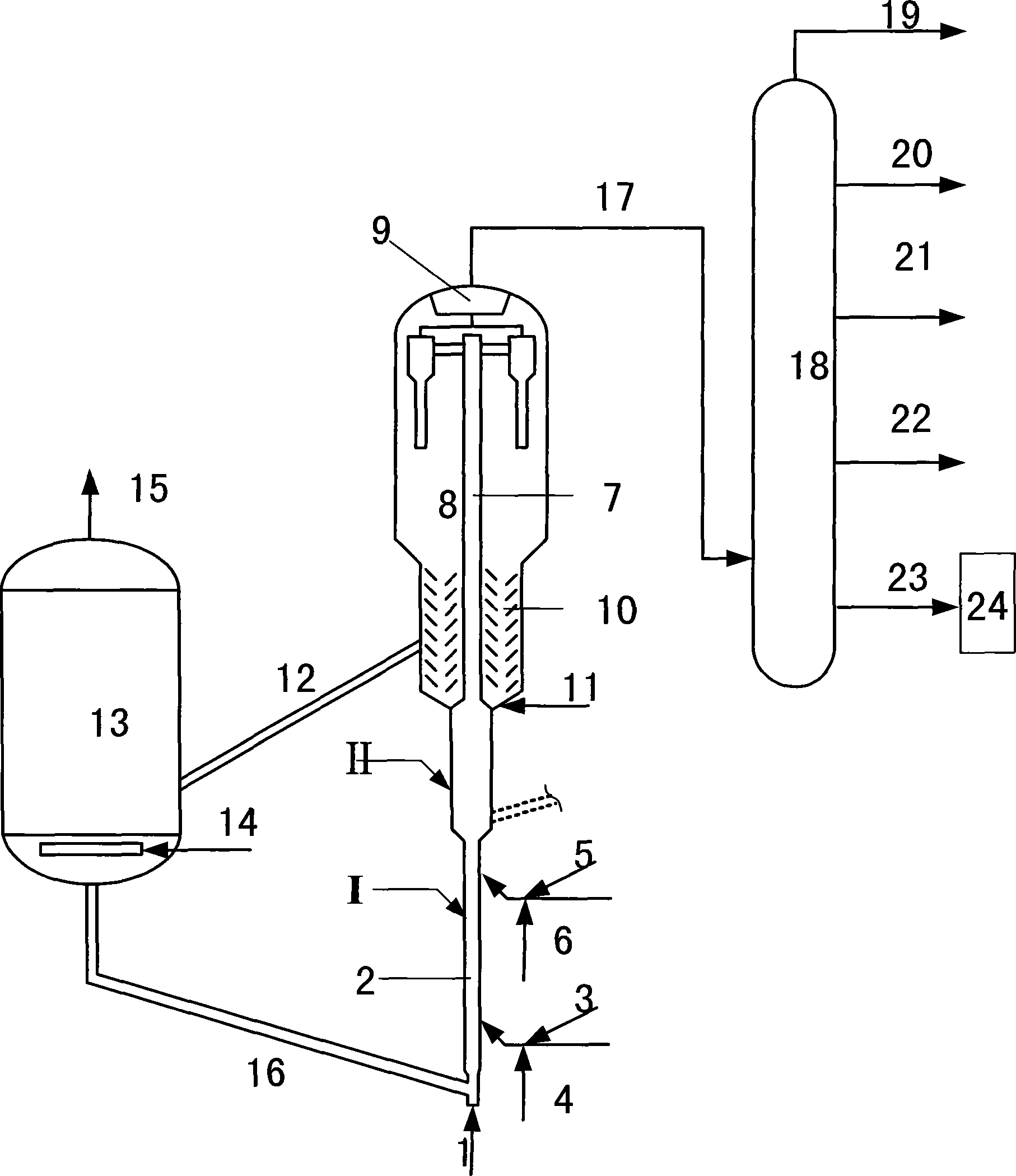

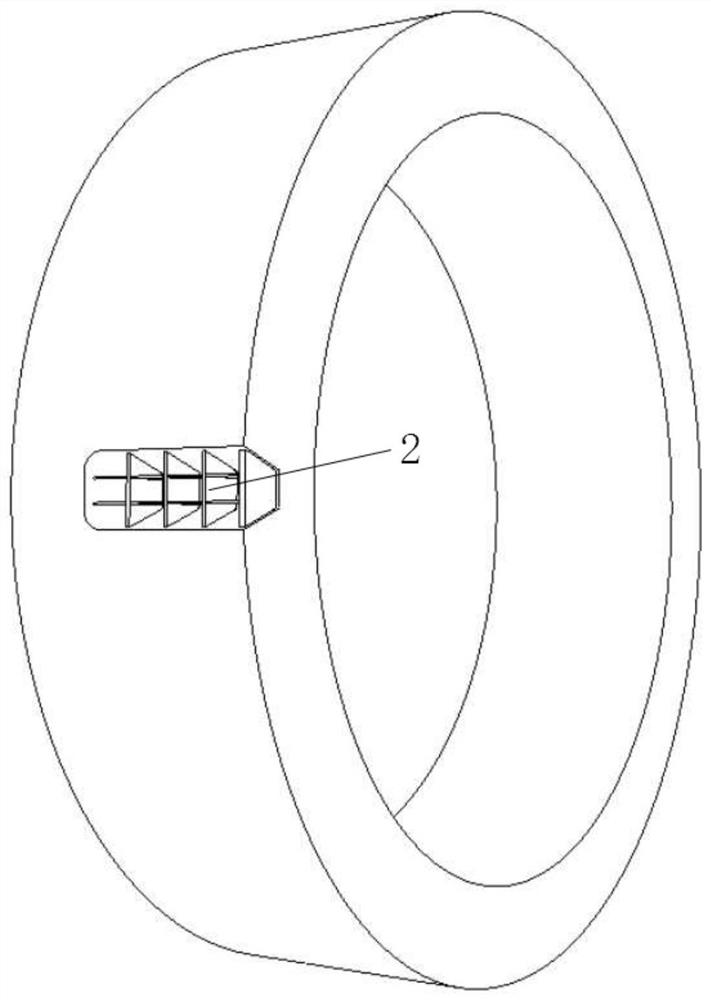

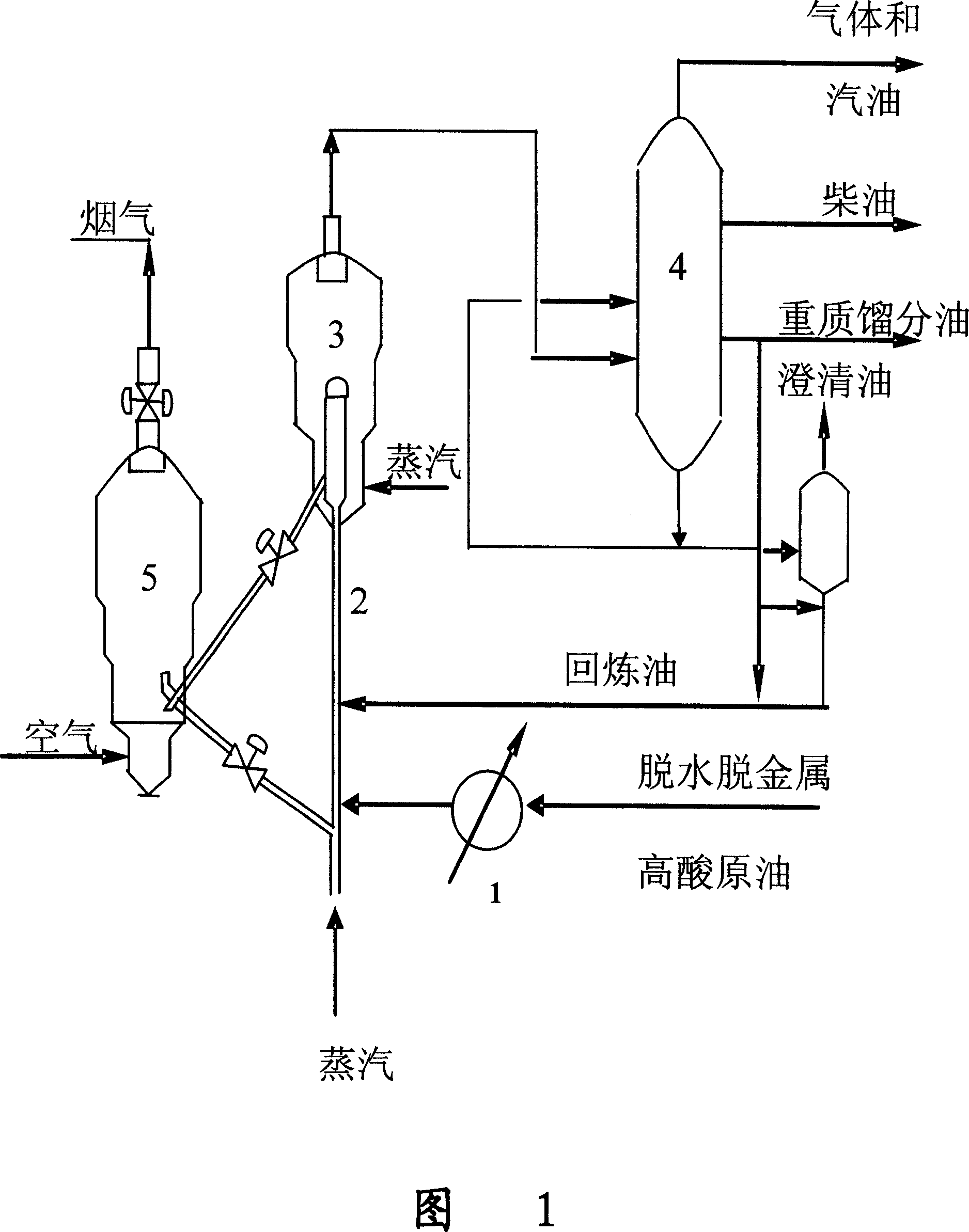

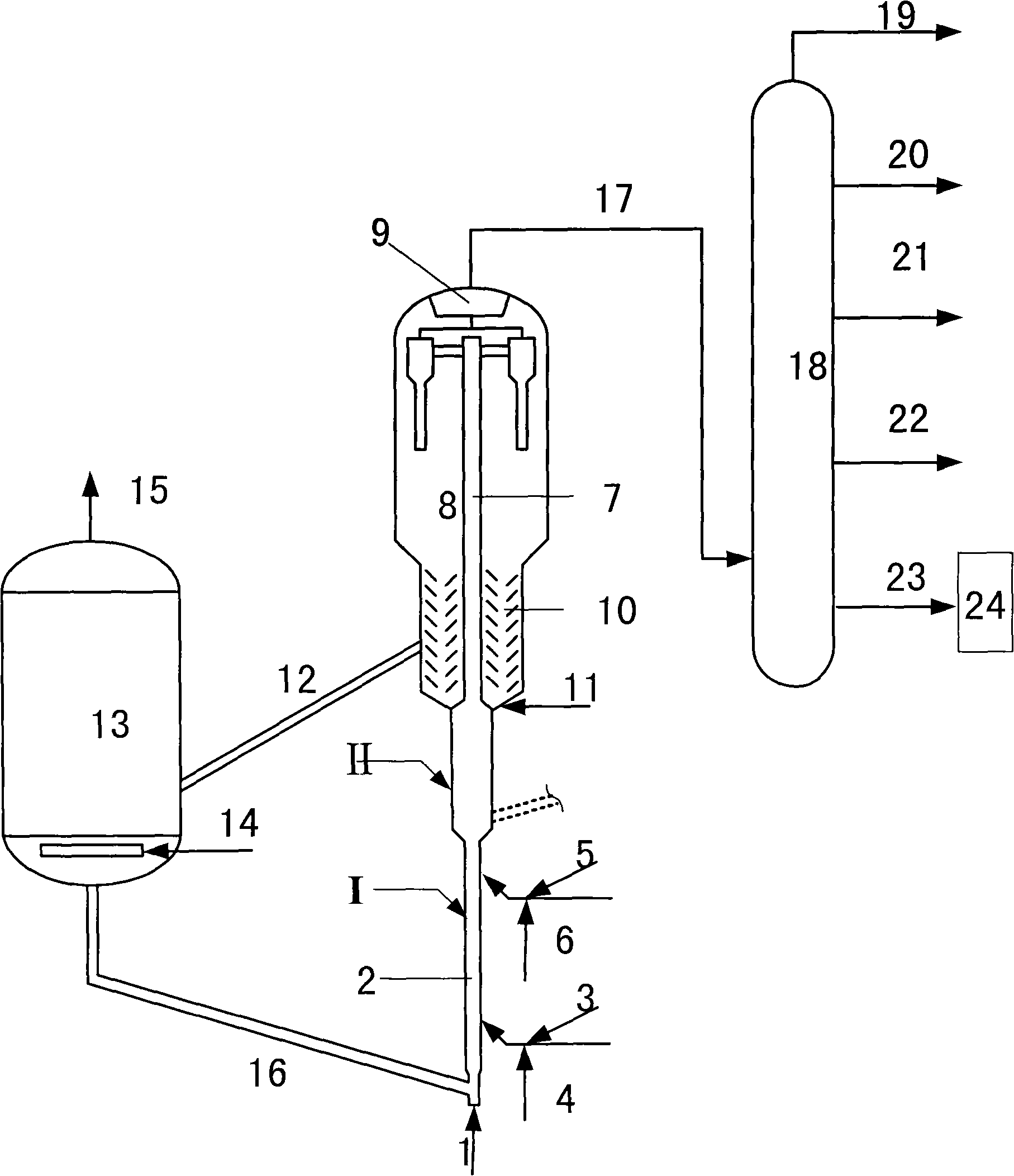

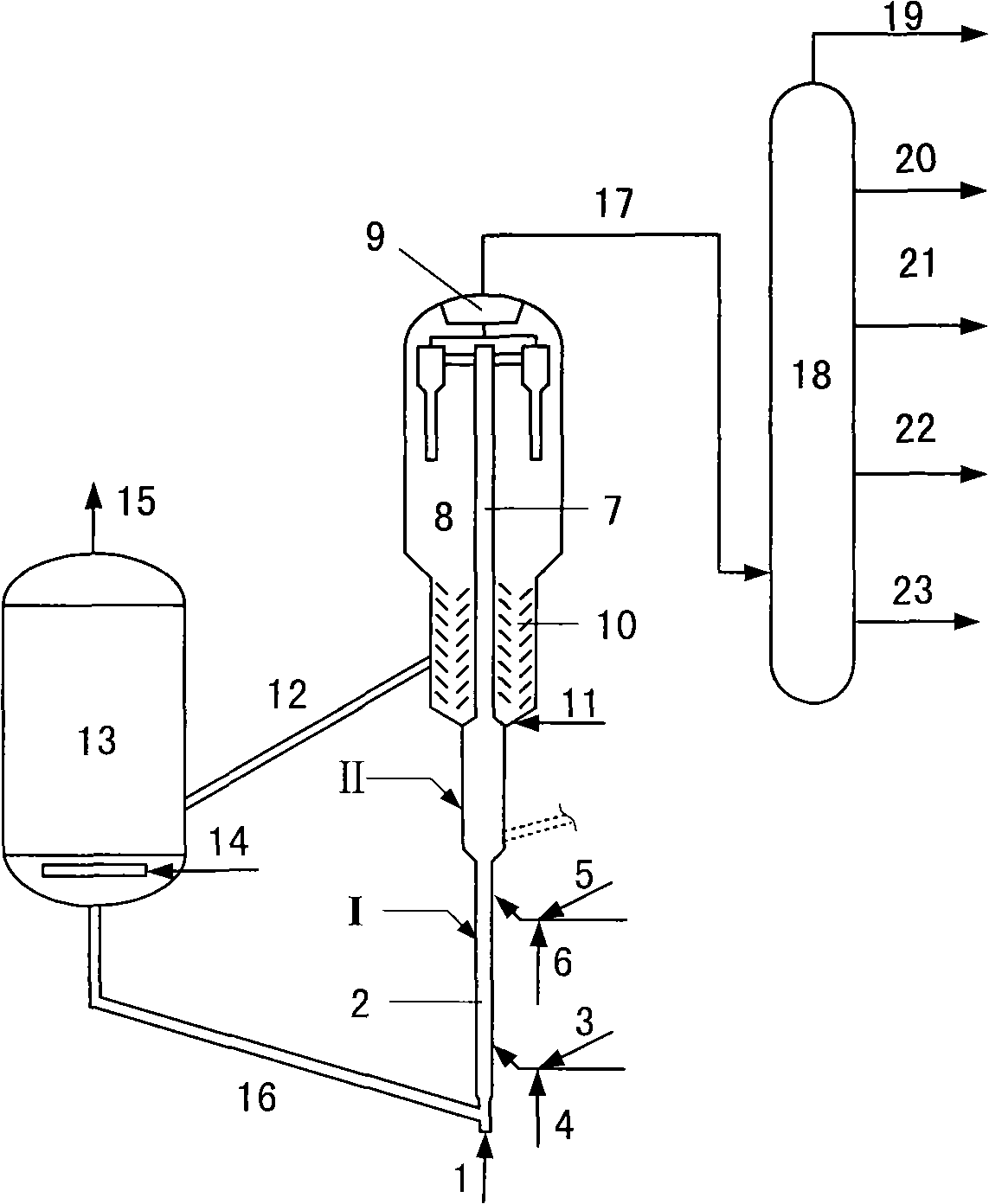

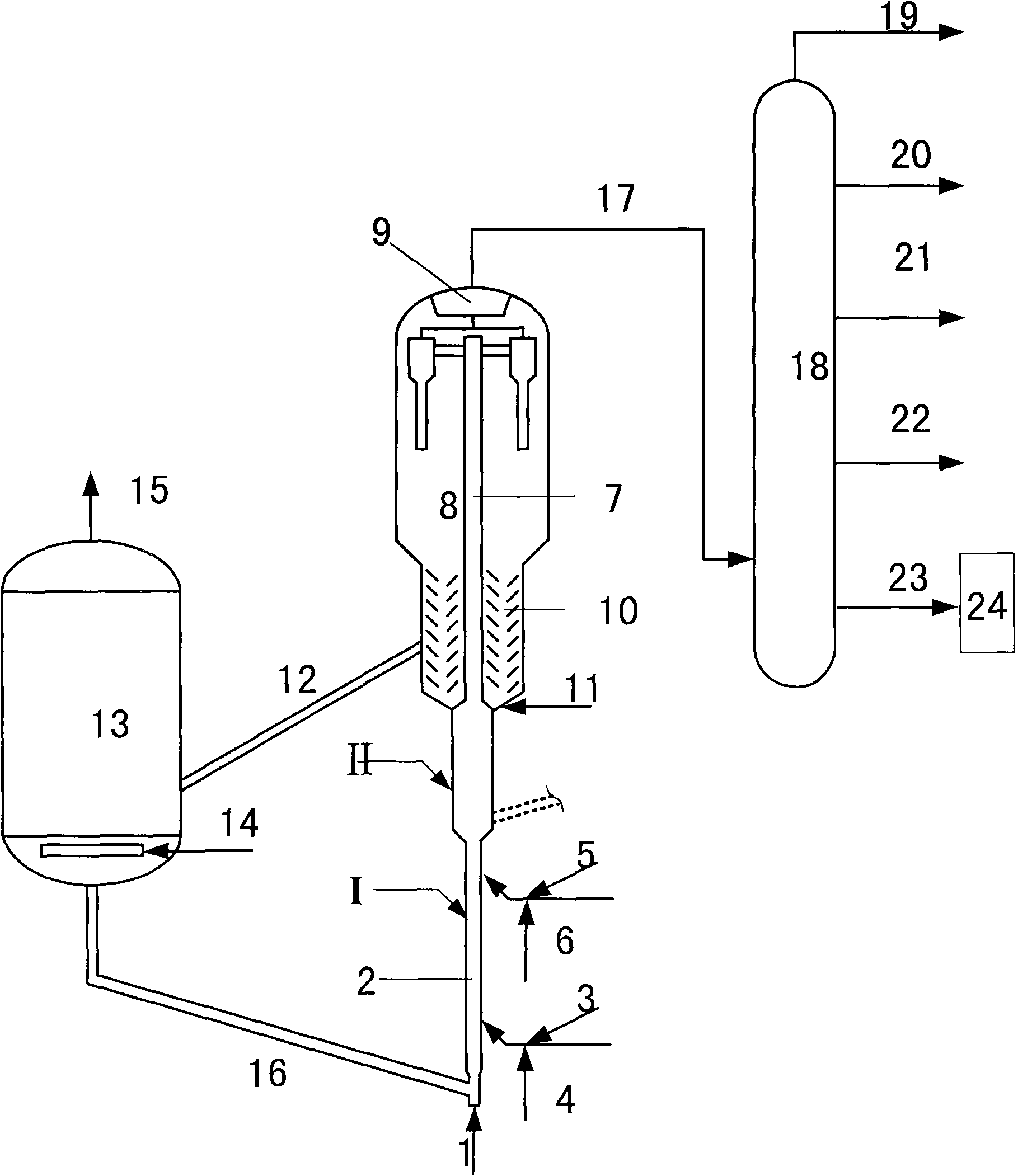

Method for processing crude oil with high acid value

ActiveCN1827744AEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

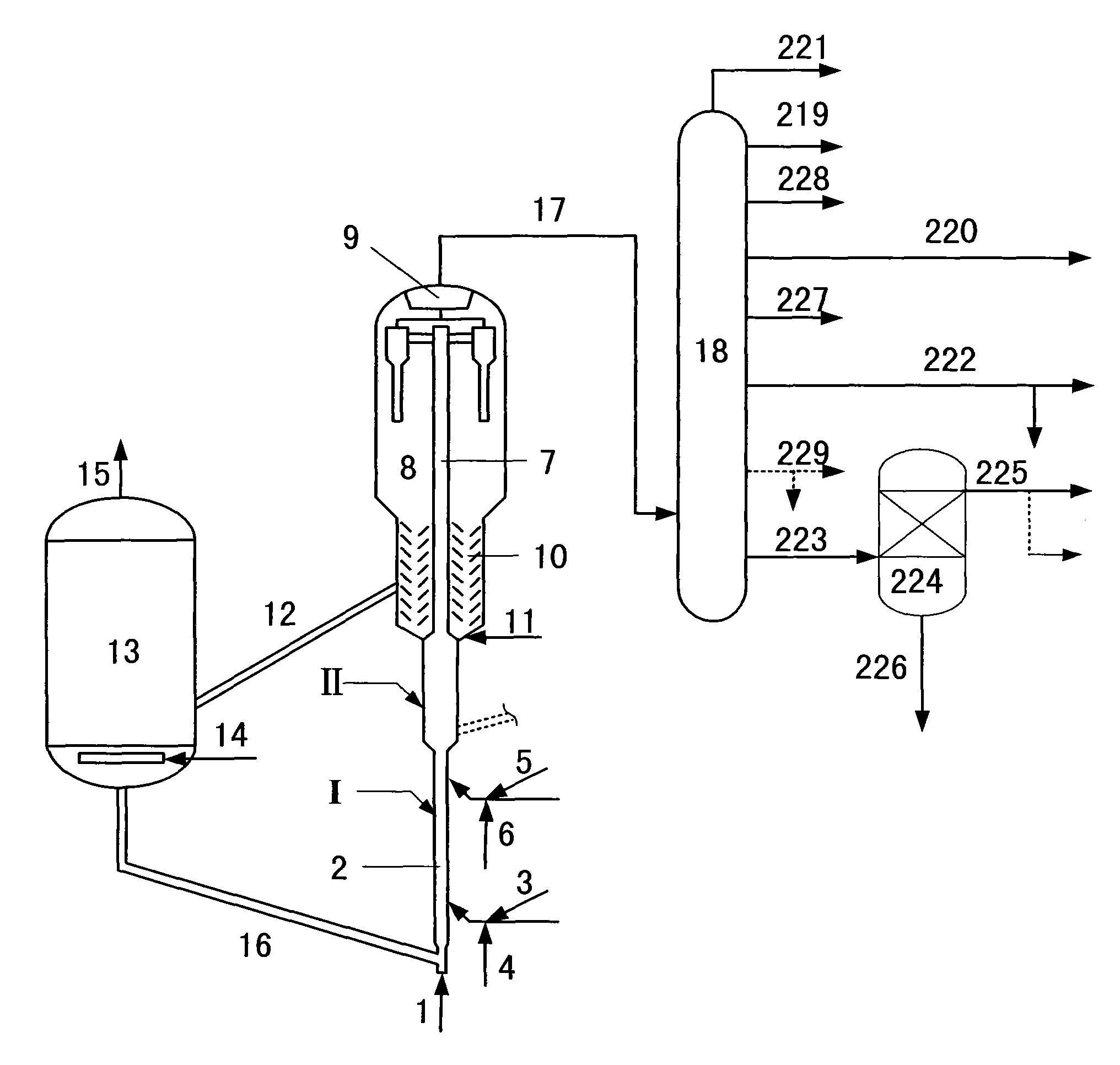

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

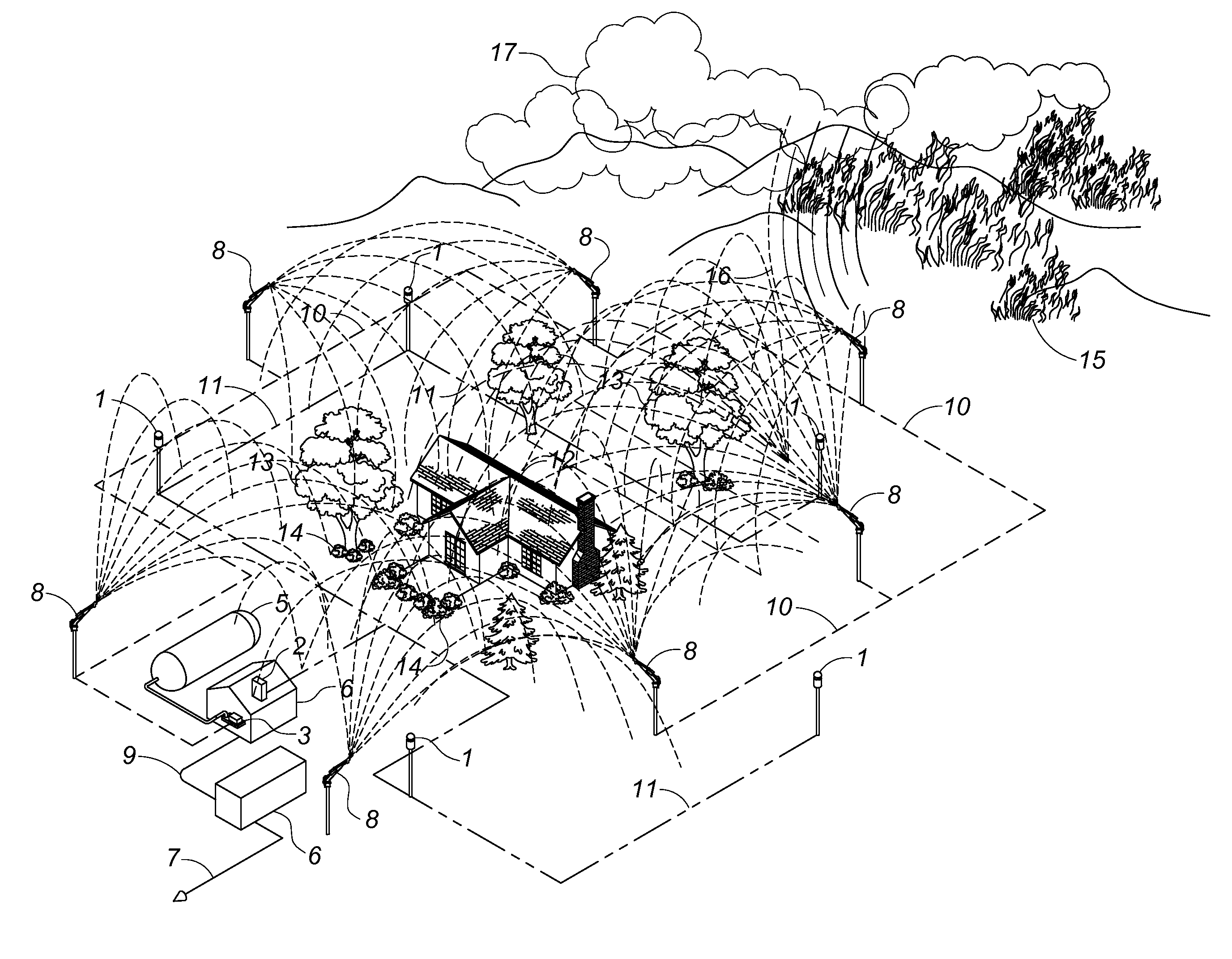

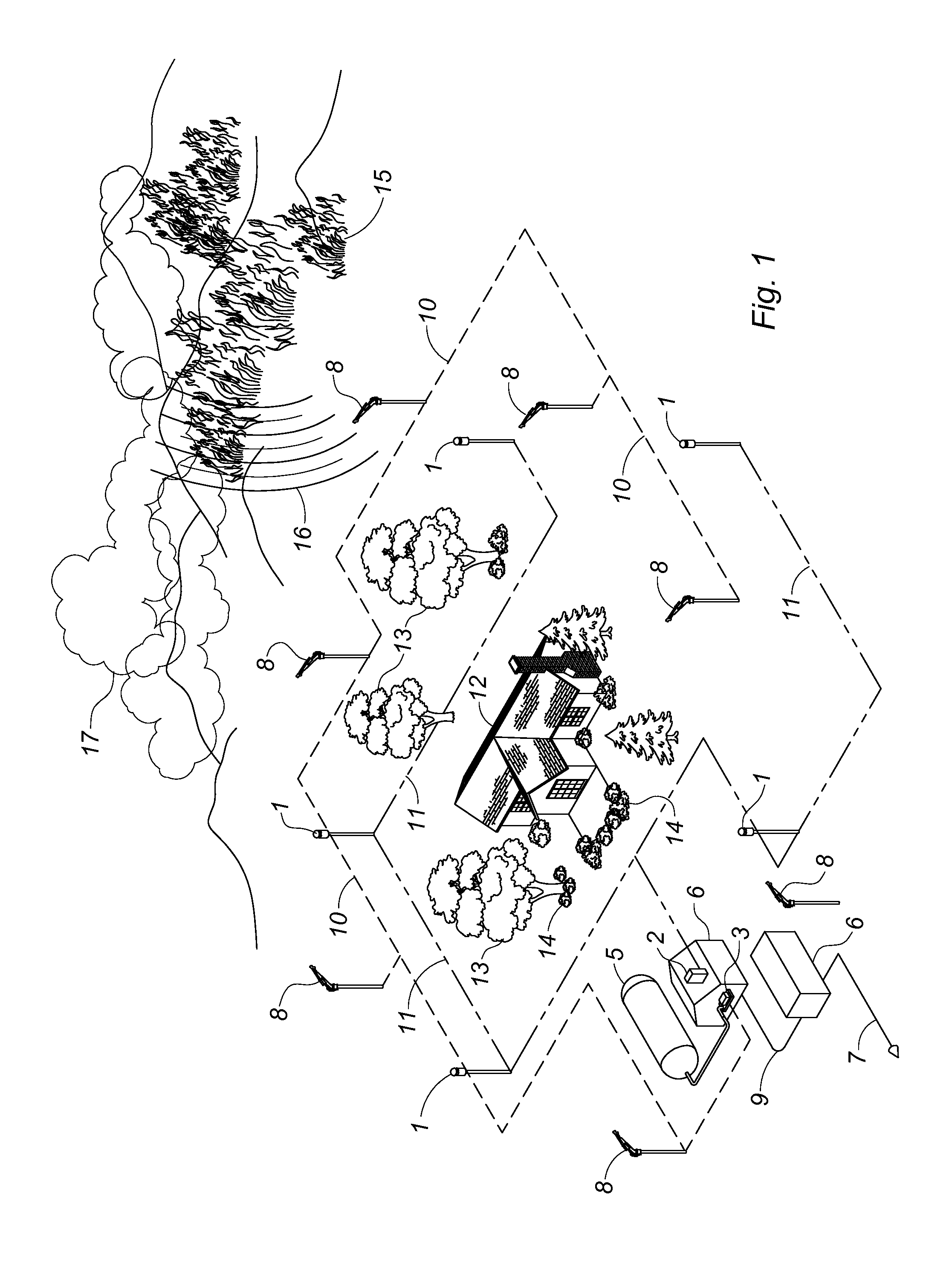

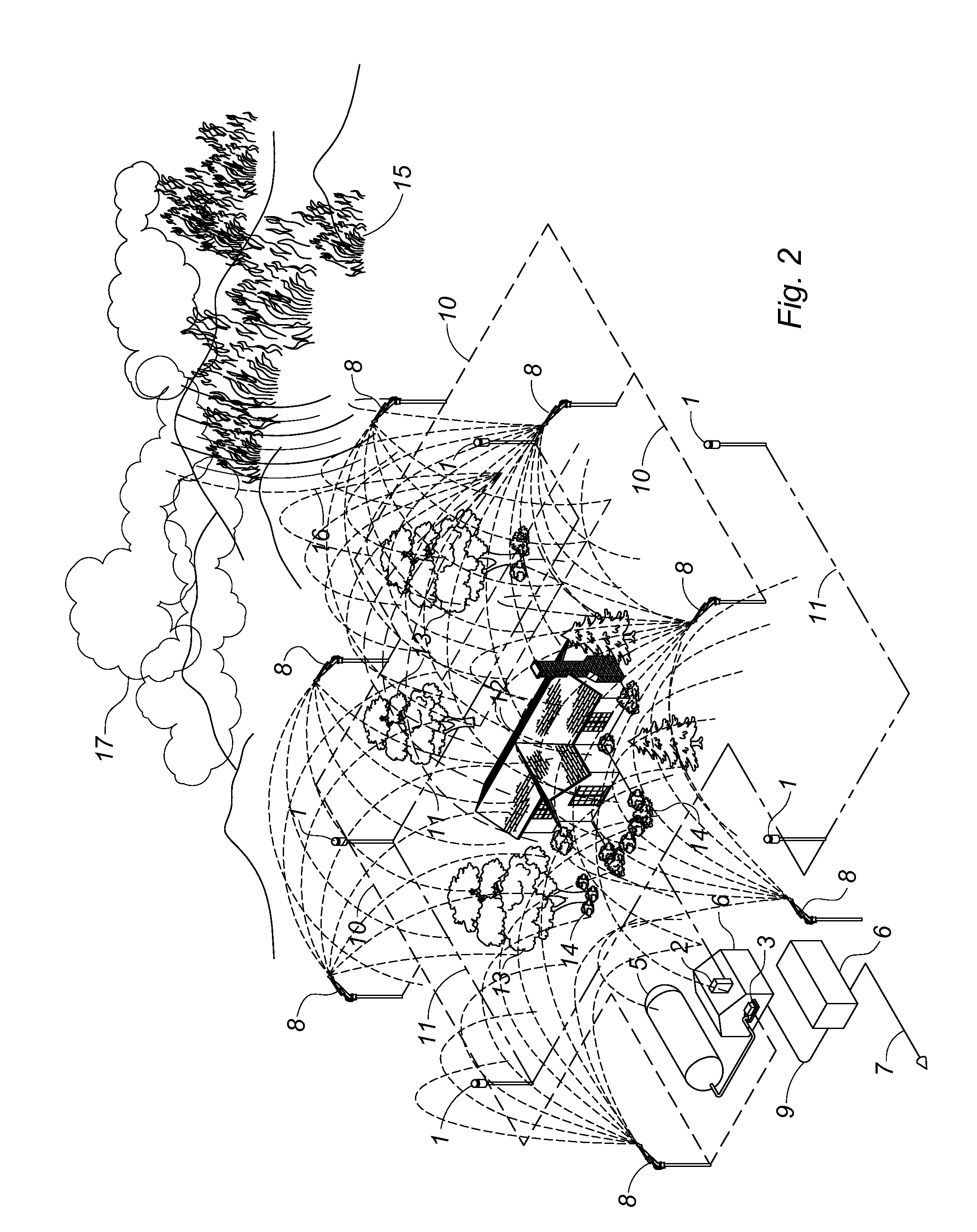

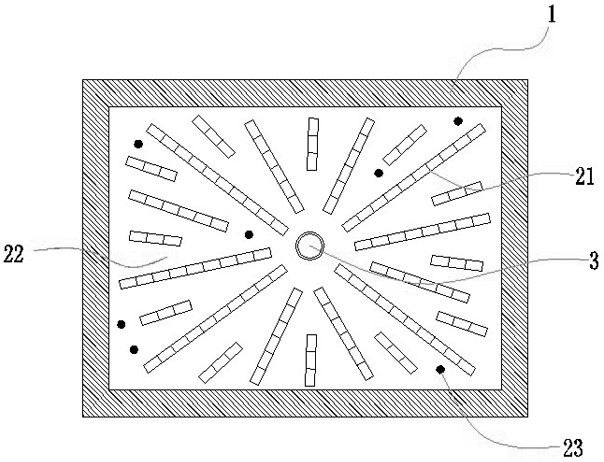

Wildfire suppression system

InactiveUS20150129245A1Inhibition of harmful effectsProvide protectionFire rescueBoring toolsDistribution systemEngineering

A wildfire suppression system is shown that includes a detector that can identify a wildfire threat from an approaching wildfire. When a wildfire is detected, a fire suppression system is activated to pump a fire retardant product, such as water or foam, through a fire retardant distribution system to supply the fire retardant to a series of water dispersion devices that are positioned to protect a structure and a set of landscape elements such as trees, flowers, bushes, and shrubs. Various embodiments can include automatic notification to local fire and police authorities of the presence of the wildfire, and can also include local electrical power generating units that can provide the electrical power needed to operate and control the wildfire suppression system.

Owner:WEBER JUNATA E

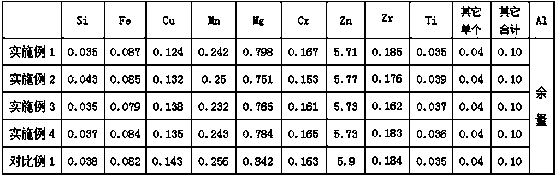

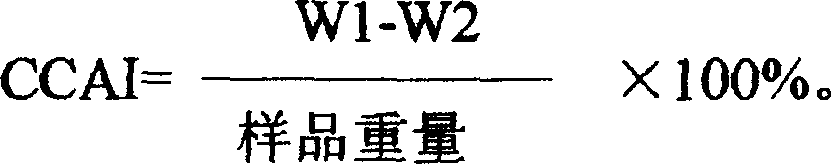

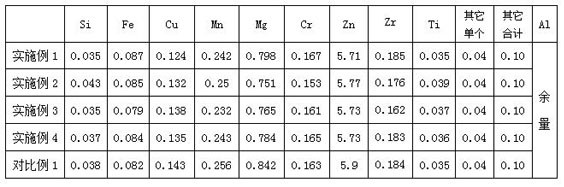

Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and preparation method thereof

ActiveCN110184513AImprove mechanical propertiesAccelerated corrosionStress relievingUltimate tensile strength

The invention aims to provide an Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and a preparation method thereof. The aluminum alloy material is prepared from, by mass, smaller than or equal to 0.1% of Si, smaller than or equal to 0.1% of Fe, 0.12%-0.14% of Cu, 0.23%-0.25% of Mn, 0.75%-0.8% of Mg, 0.15%-0.17% of Cr, 5.7%-5.8% of Zn, 0.16%-0.19% of Zr, 0.02%-0.04% of Ti, wherein the ratio of Fe to Si ranges from 1.8 to 2.5, and the ratio of Zn to Mg is controlled to range from 7.1 to 7.7. The preparation method comprises the steps of smelting, refining, essence melting, casting, homogenization annealing, extruding, solid solution quenching, stress relieving and aging treatment. According to the Al-Zn-Mg-Cu aluminum alloy profile with the high stress corrosion resistance and the preparation method thereof, the material shows good mechanical strength and stress corrosion resistance, and the material is especially suitable for aluminum alloy structural members which are prone to stress corrosion and failure, in particular to aluminum alloy structural members subjected to tensile stress at the bottom of a rail transit or a vehicle body.

Owner:广西南南铝加工有限公司

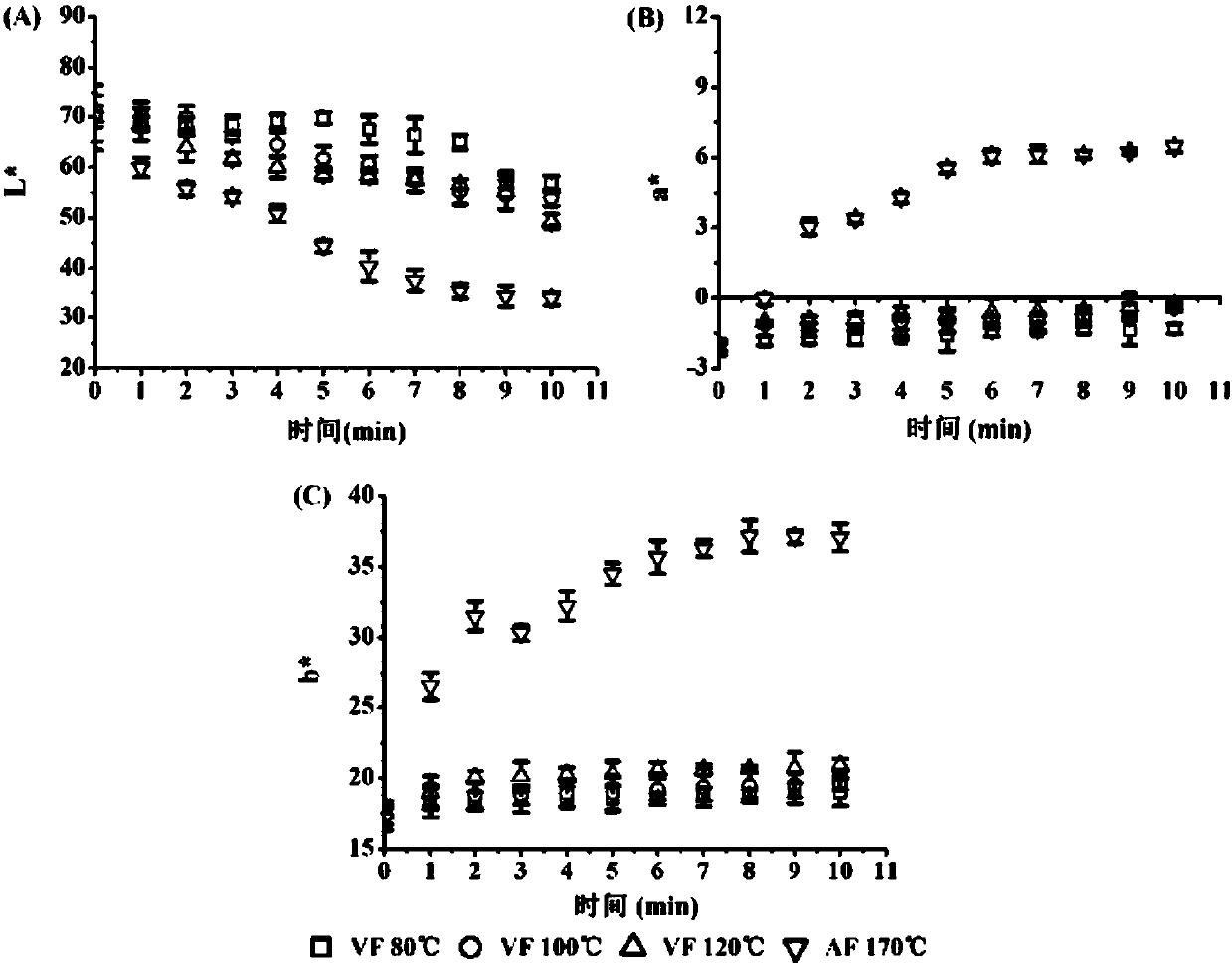

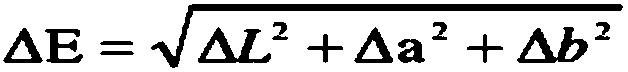

Machining process of burdock fried food

InactiveCN103478640AReduce lossesInhibition of harmful effectsFood dryingFood preparationBiotechnologyPhysical health

The invention relates to a machining process of burdock fried food. The machining process is characterized in that a burdock piece is instantly fired or baked under a vacuum low temperature state so as to manufacture a fried burdock fragile piece, the losses of natural pigment and aromatic substances are greatly reduced, the adverse effects of microbes and enzymes are restrained, the original colour and lustre and scent are fully kept, and the potential safety hazard brought by the traditional high-temperature frying to the physical health of a person is avoided.

Owner:乔子凌

Processing method for vacuum freeze drying sea water fisheries products

InactiveCN101156617APrevent decomposition or oxidationInhibition of harmful effectsMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsChemistryFreeze dry

The invention discloses a processing method for vacuum freeze-dry marine fish products, which includes the procedures of water thaw, quick freezing, vacuum freeze-dry, and the like. The invention facilitates the long-distance transportation and the long-term storage with good nutrition keeping.

Owner:冯学军

Semi-synthesized olefins conversion catalyst containing modified nano aluminium oxide

InactiveCN1438297AHigh activityImprove wear resistanceCatalytic crackingMolecular sieve catalystsSlurryAluminium silicate

The invention is a conversion catalyzer of half-synthetical hydrocarbon, containing denaturing nano alumina. It disperses synthetic molecular screen and denaturing nano alumina containing Ce, Zr and Mg to inorganic oxide clay and natural aluminium silicate clay, mixes into serum, and makes jet-drying shaping, washing and drying to get the conversion catalyzer. It is especially applied to process heavy raw materials with Ni and V.

Owner:吉林省嘉孚化学工业股份有限公司

Nickel-based welding rod and preparation method thereof

ActiveCN109454357AIncrease the amount of depositionFast meltingWelding/cutting media/materialsSoldering mediaChemical compositionIron powder

The invention provides a nickel-based welding rod. The nickel-based welding rod comprises a core wire and a flux coating, wherein the chemical components of the core wire comprise, by weight, less than or equal to 0.2% of C, 2-5% of Mn, 0.6-1.8% of Si, 10-20% of Cr, less than or equal to 0.4% of Al, less than or equal to 0.3% of Ti, 2-8% of W, less than or equal to 0.005% of S, less than or equalto 0.006% of P, and the balance N; the flux coating comprises, by weight, 20-35% of marble, 15-45% of fluorite, 8-18% of quartz, 2-8% of rutile, 1-5% of titanium dioxide powder, 2-6% of ferrovanadium,2-6% of ferromanganese, 4-7% of ferrotungsten, and the balance iron powder. The nickel-based welding rod has the technical effects of low cost, good mechanical performance of welded joints and good weld shaping.

Owner:DONGGUAN UNIV OF TECH

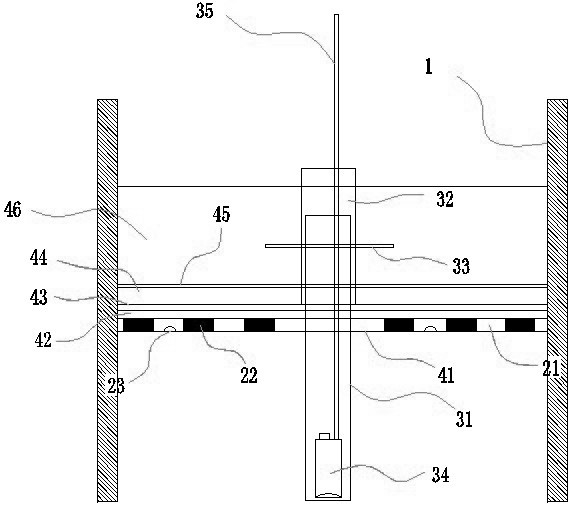

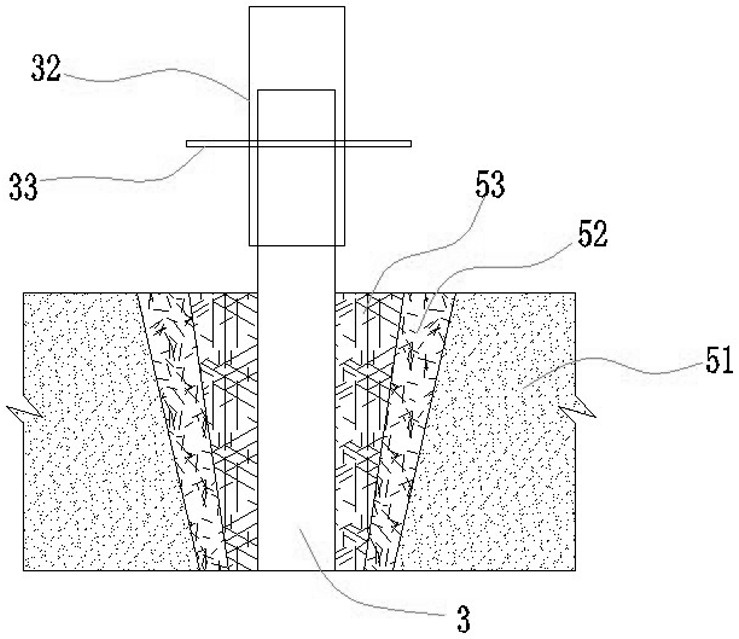

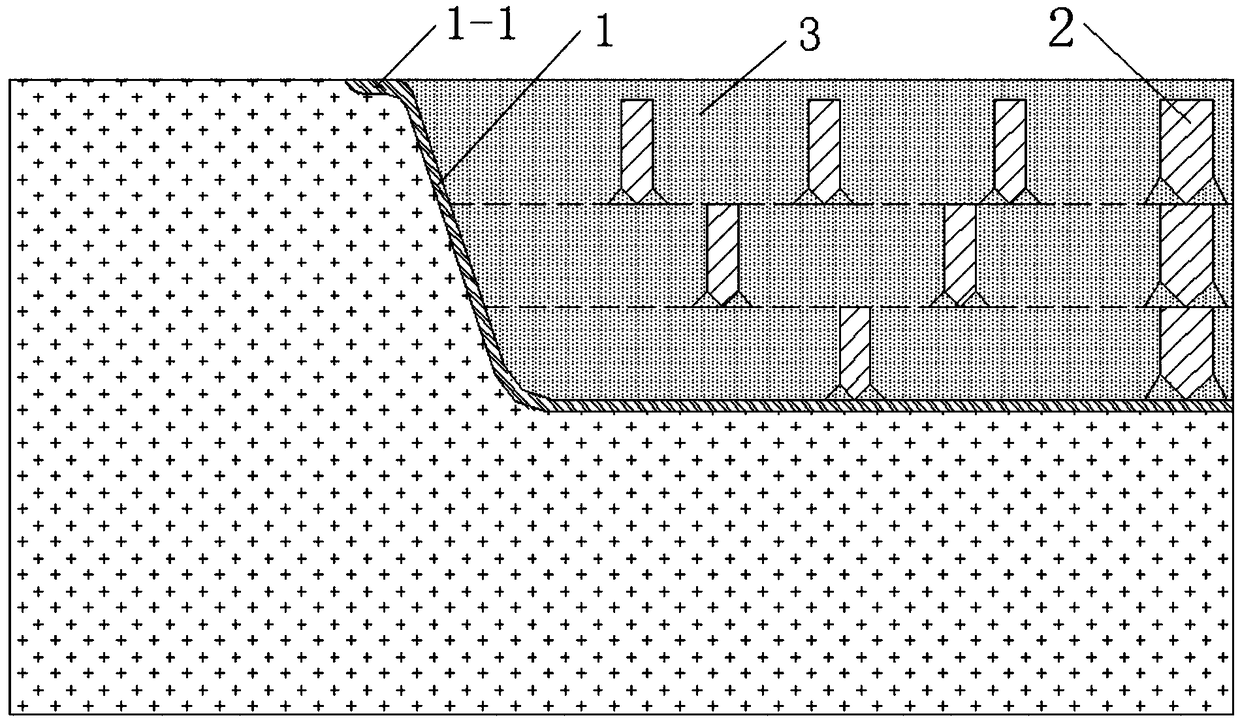

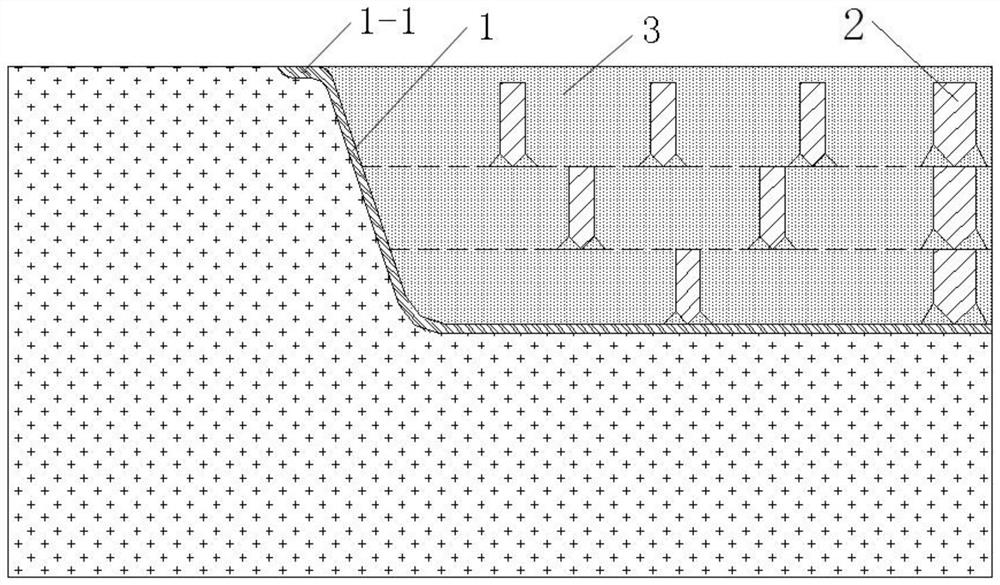

Substrate water gushing and sand gushing treatment method

InactiveCN112281882AEffectively closedInhibition of harmful effectsFoundation engineeringBrickReinforced concrete

The invention belongs to the technical field of building construction, and particularly relates to a substrate water gushing and sand gushing treatment method. The treatment method comprises the following steps that S1, surveying and setting out are carried out, and the position of a secondary excavation foundation pit is determined; S2, supporting piles and a waterproof curtain are constructed; S3, a foundation pit is excavated; S4, the soil surface is excavated to a preset elevation and flattened, and a submersible pump is placed to pump and drain accumulated water; S5, water and sand gushing points on the soil surface of the substrate are found out, and a water flowing pipeline is built by using bricks, so that water flowing out of the water gushing points is collected to a middle dewatering well to be discharged; S6, a formwork and plastic cloth are laid on the top faces of the bricks; S7, a water stop steel shaft is installed in the dewatering well, and a cushion layer is poured;S8 a waterproof layer is laid, and concrete is poured; and S9, the dewatering well is plugged. According to the substrate water gushing and sand gushing treatment method, the bottom surface of the foundation pit can be rapidly and effectively sealed, the harmful effect of water gushing and sand gushing of the substrate on the foundation pit is restrained to a large extent, and safe and smooth construction of a main body reinforced concrete structure is guaranteed; and the construction method is simple, low in cost and remarkable in effect.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Ready-to-eat large yellow croaker vacuum deep-fried food and production technology thereof

The invention relates to a ready-to-eat large yellow croaker vacuum deep-fried food. The raw materials of the ready-to-eat large yellow croaker vacuum fried food comprise the following components in parts by weight: 120-150 parts of fish meat of large yellow croakers, 20-35 parts of bone glue, 10-25 parts of pomelo peel, 3-5 parts of olive oil, 4-7 parts of corn oil, 5-15 parts of seasonings, 20-35 parts of black bean powder, 10-20 parts of honeycombs, 25-45 parts of nori and sesame seed powder, 2-5 parts of lemons, 5-9 parts of an additive, 5-10 parts of okra, 5-10 parts of ginseng fruits and 5-10 parts of arctium lappa. According to the ready-to-eat large yellow croaker vacuum deep-fried food disclosed by the invention, a vacuum deep-frying manner is used for replacing a conventional high-temperature deep-frying technology, so that the loss of nutrient substances is greatly reduced, the detrimental effects of microbes and enzymes are restrained, and the original fragrance and the original nutrition are sufficiently reserved. The ready-to-eat large yellow croakers prepared by the production technology disclosed by the invention are good in mouth feel, long in storage period, free from preservatives, convenient to eat and carry and simple in production method and technology, and industrialized production is easy to realize.

Owner:ZHEJIANG OCEAN UNIV

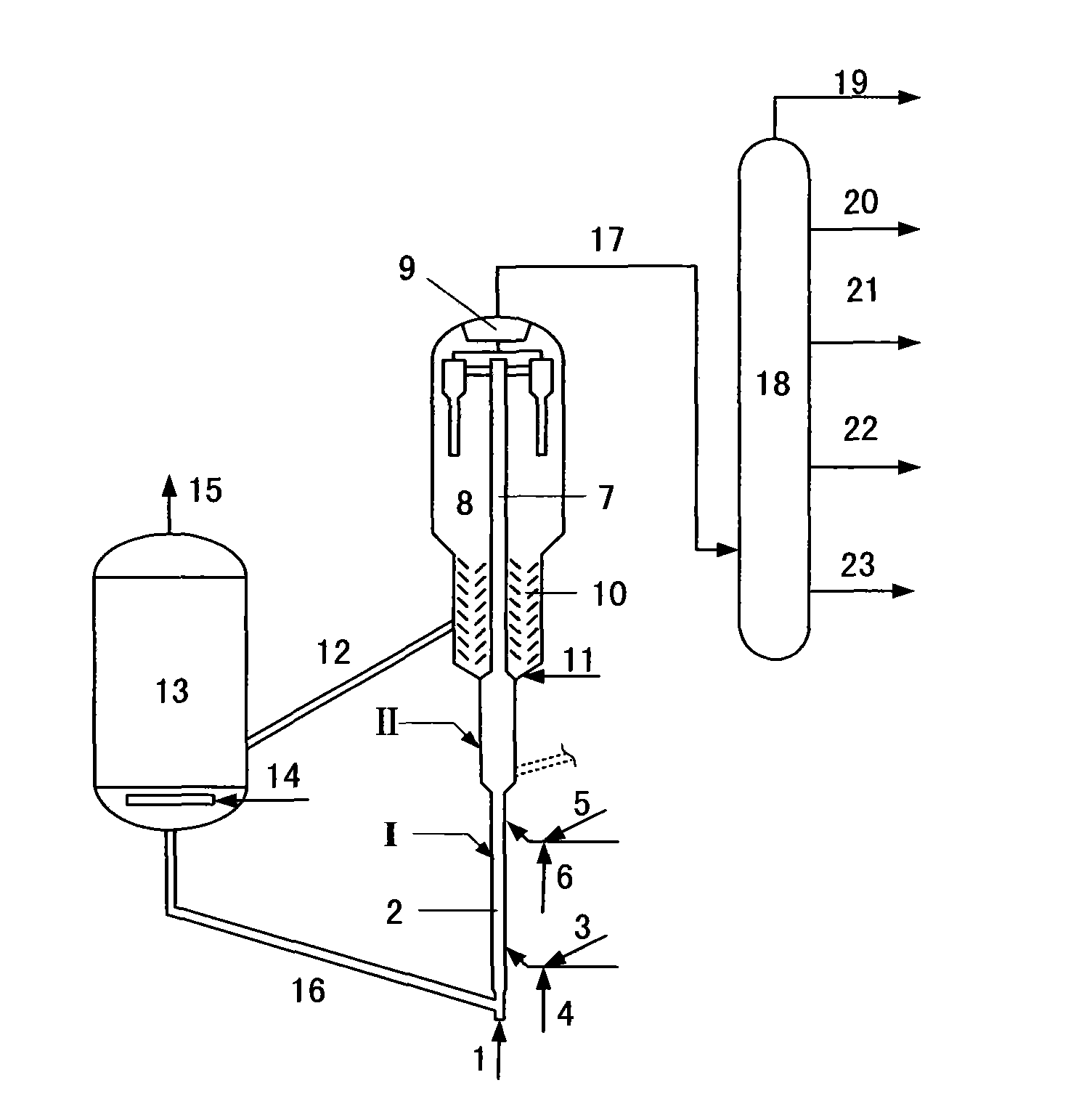

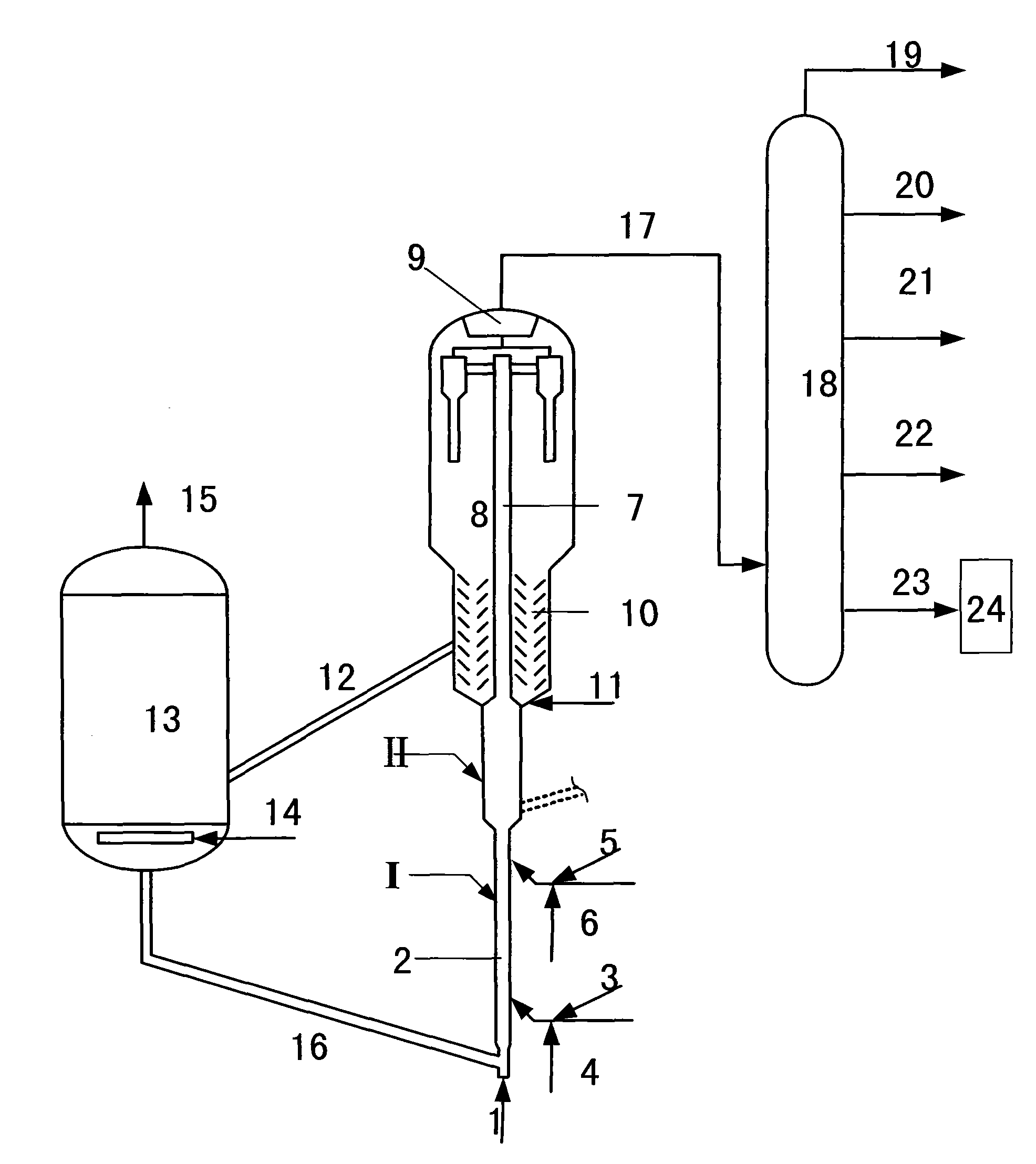

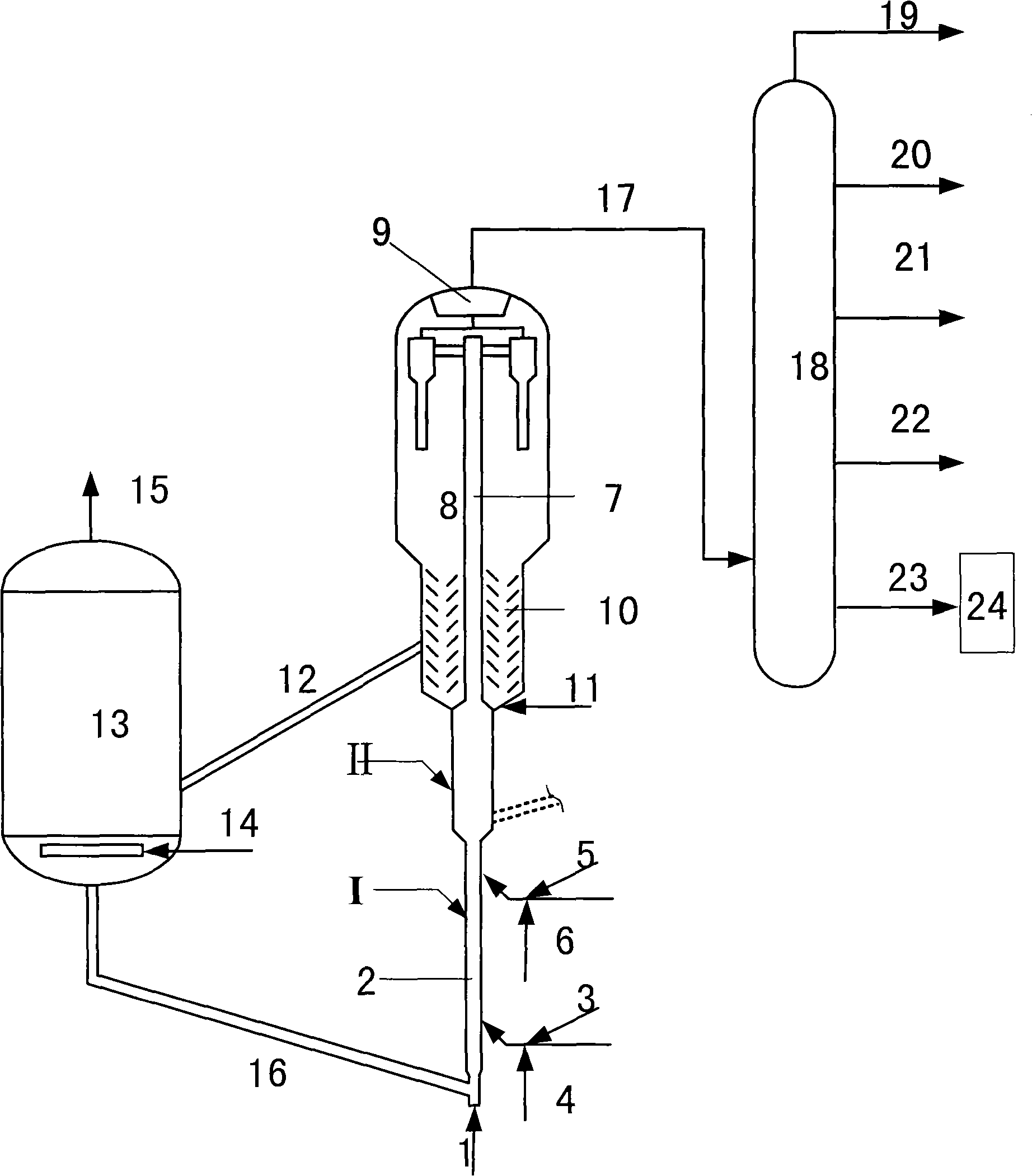

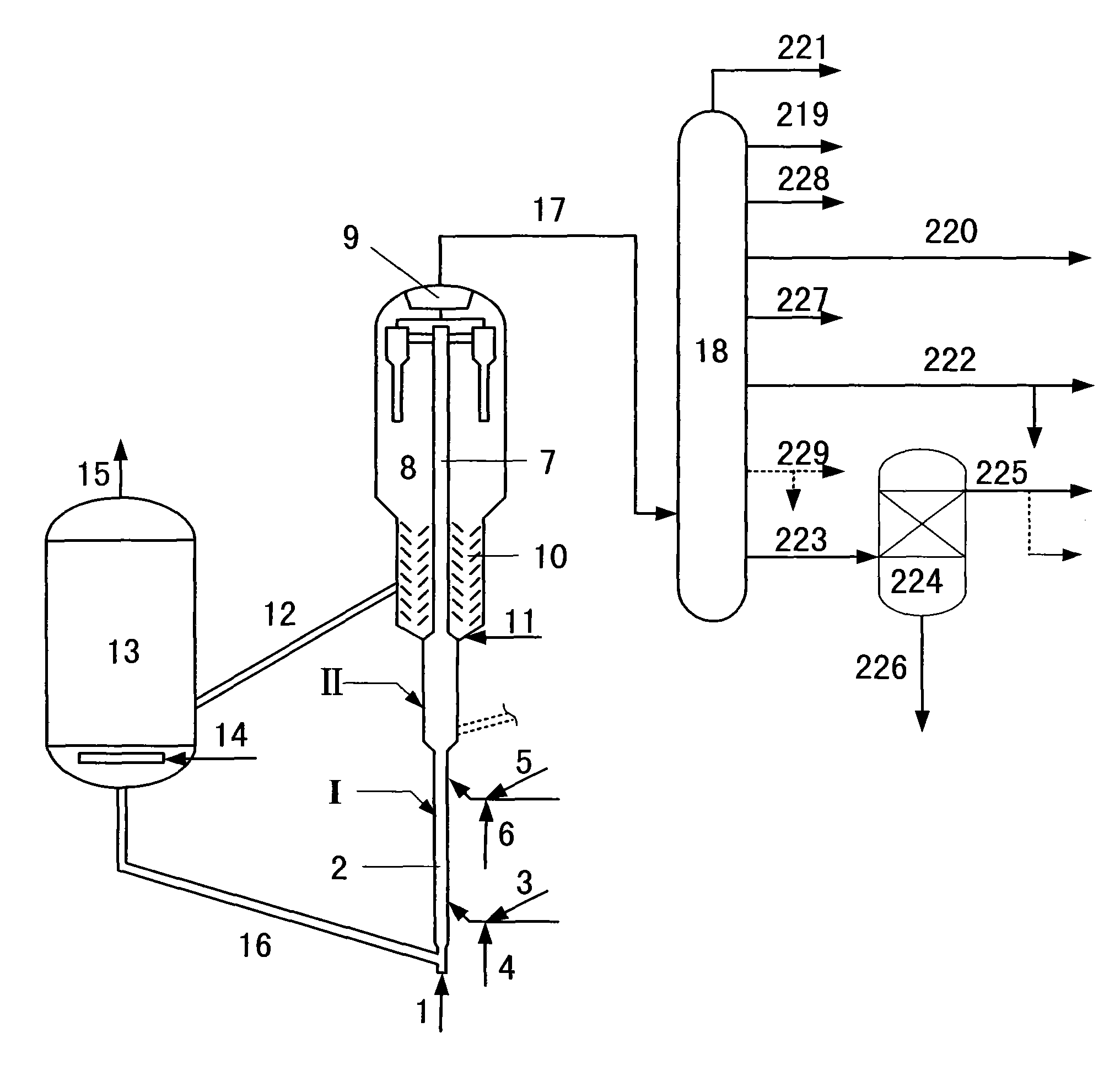

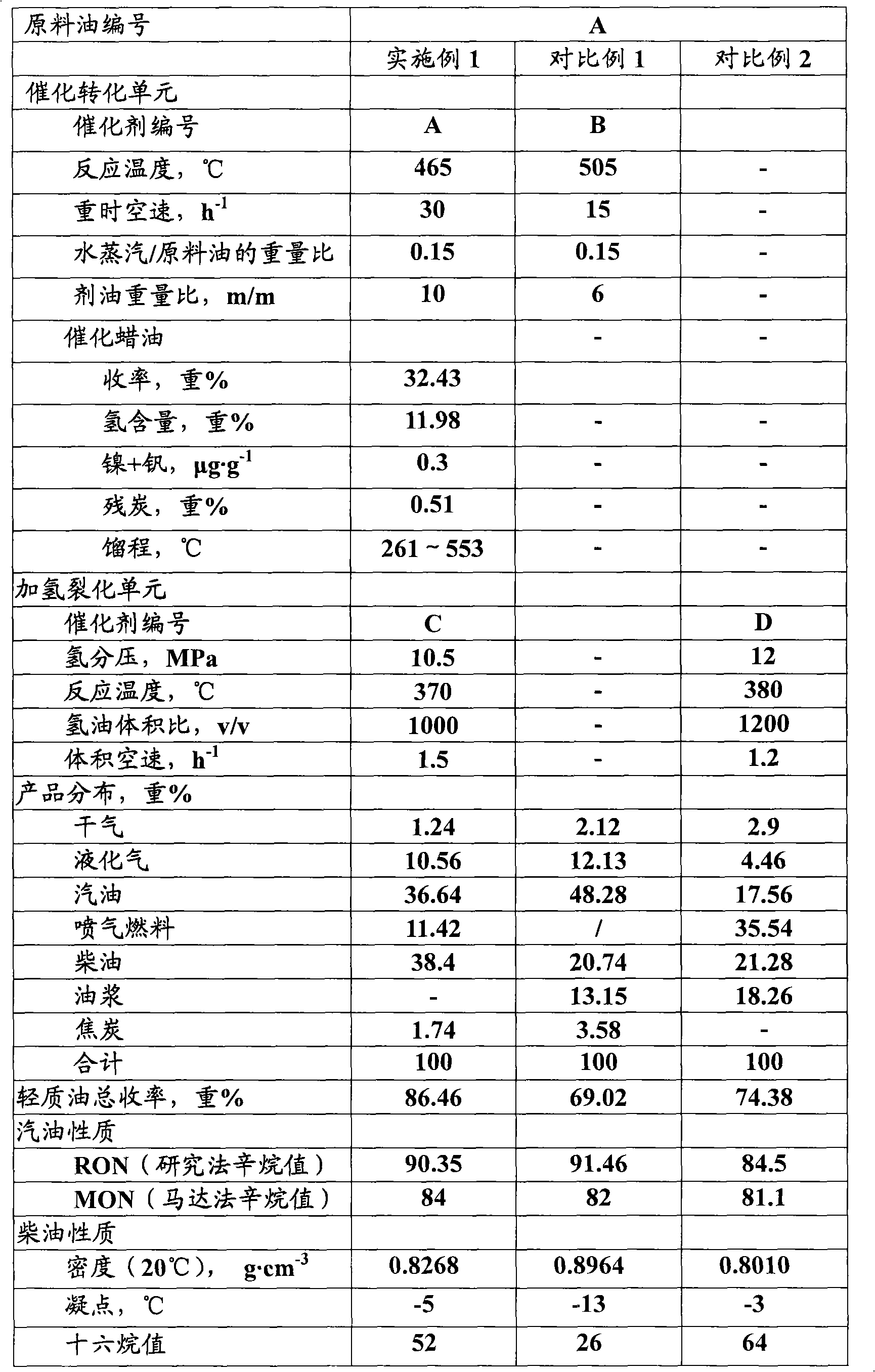

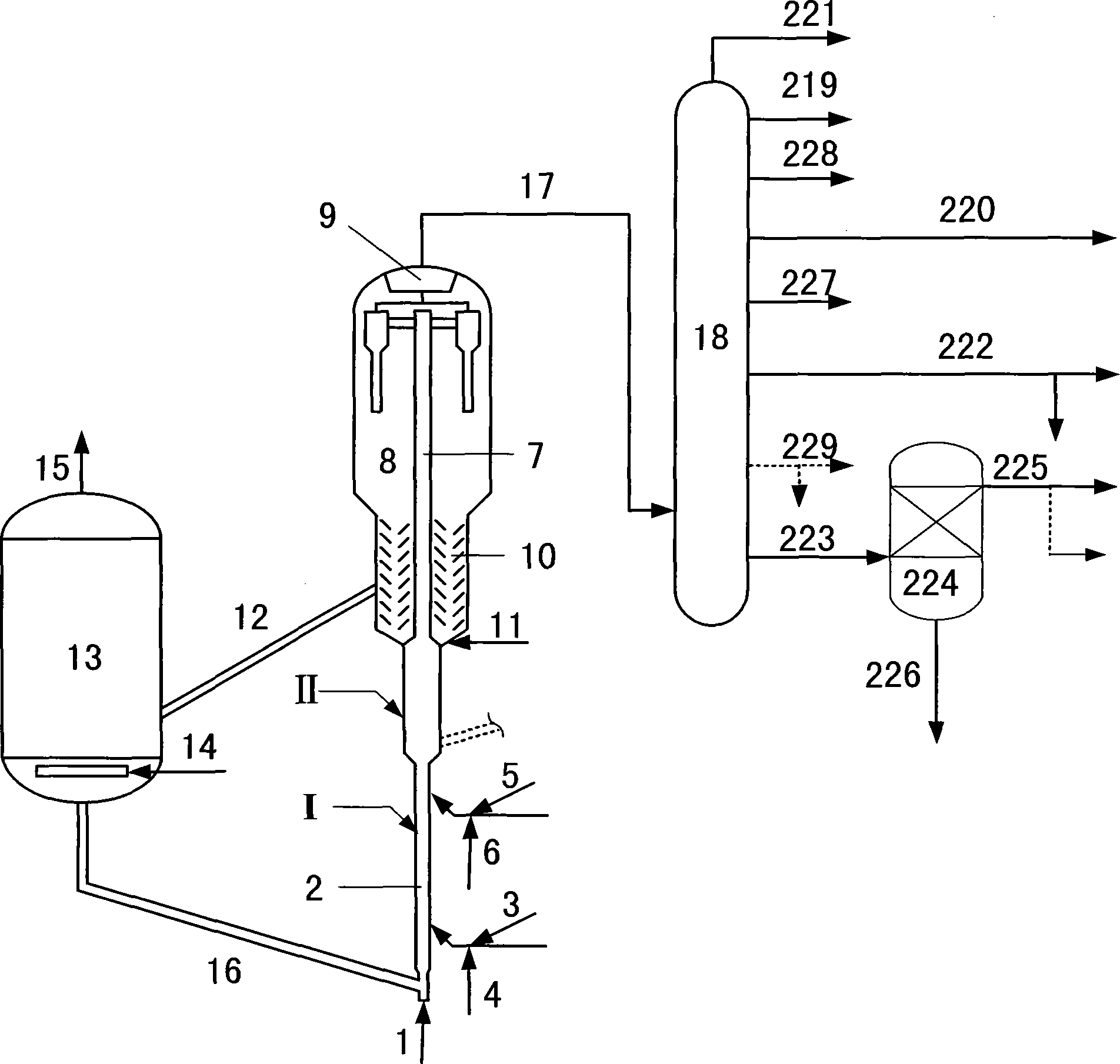

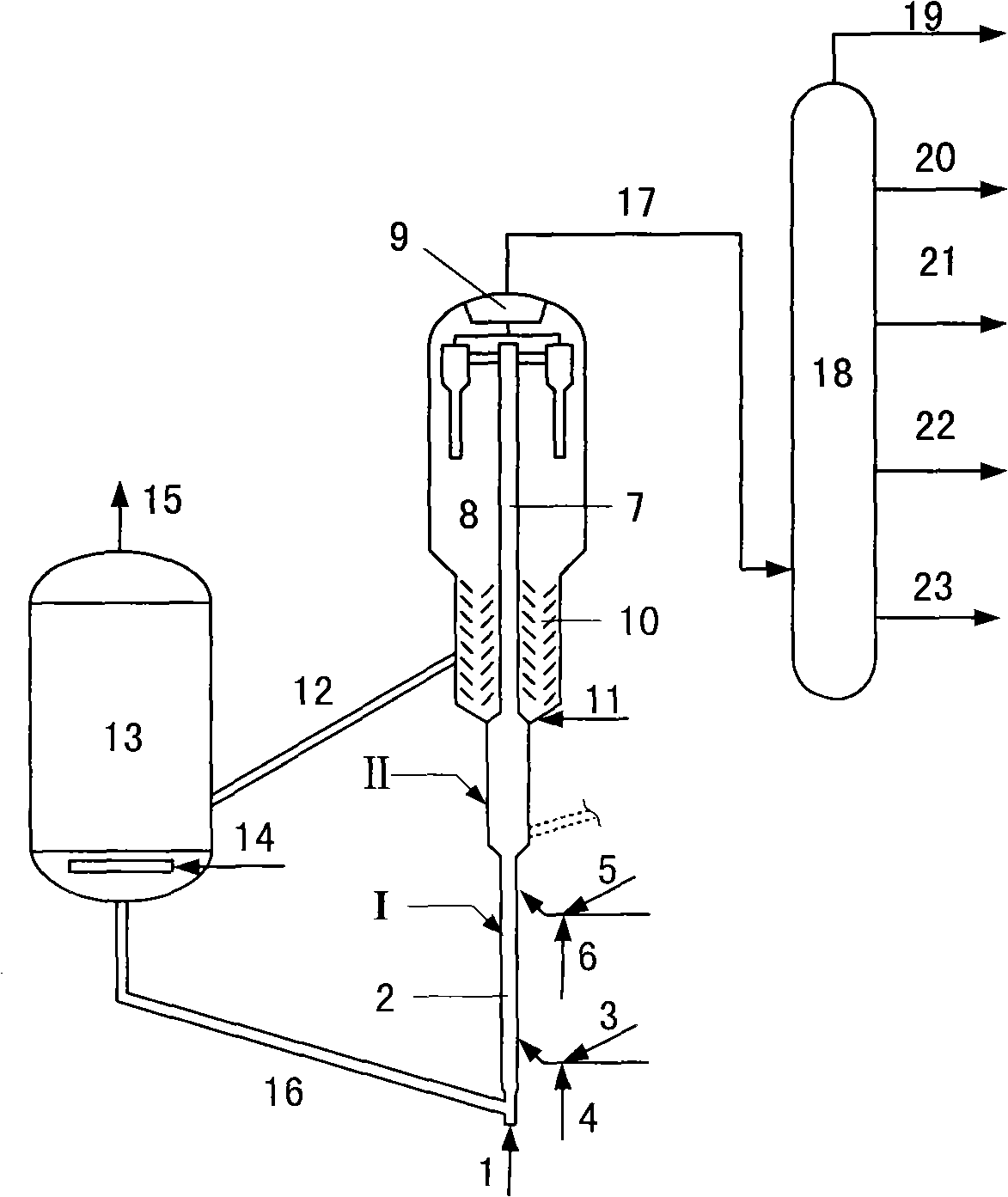

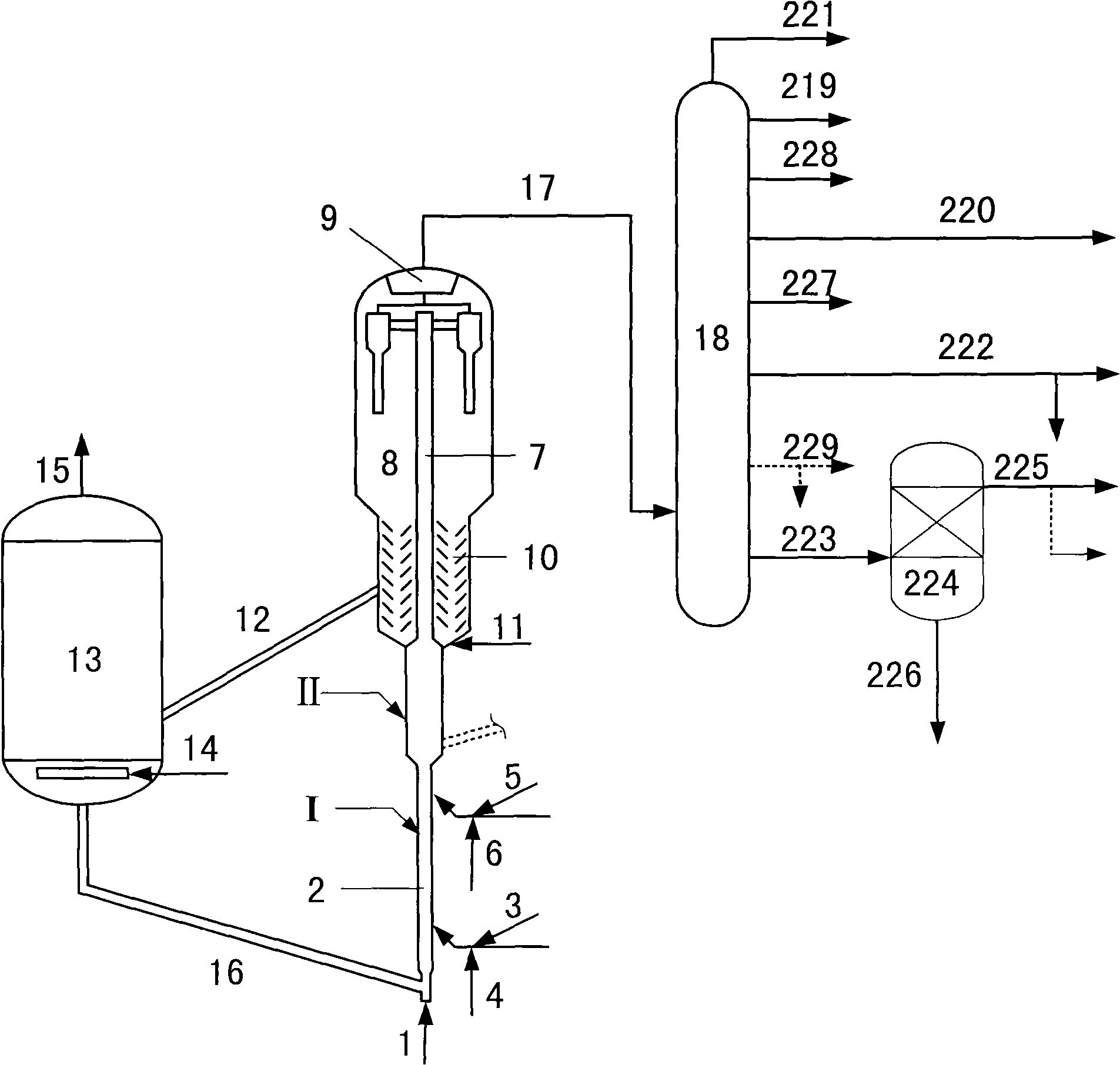

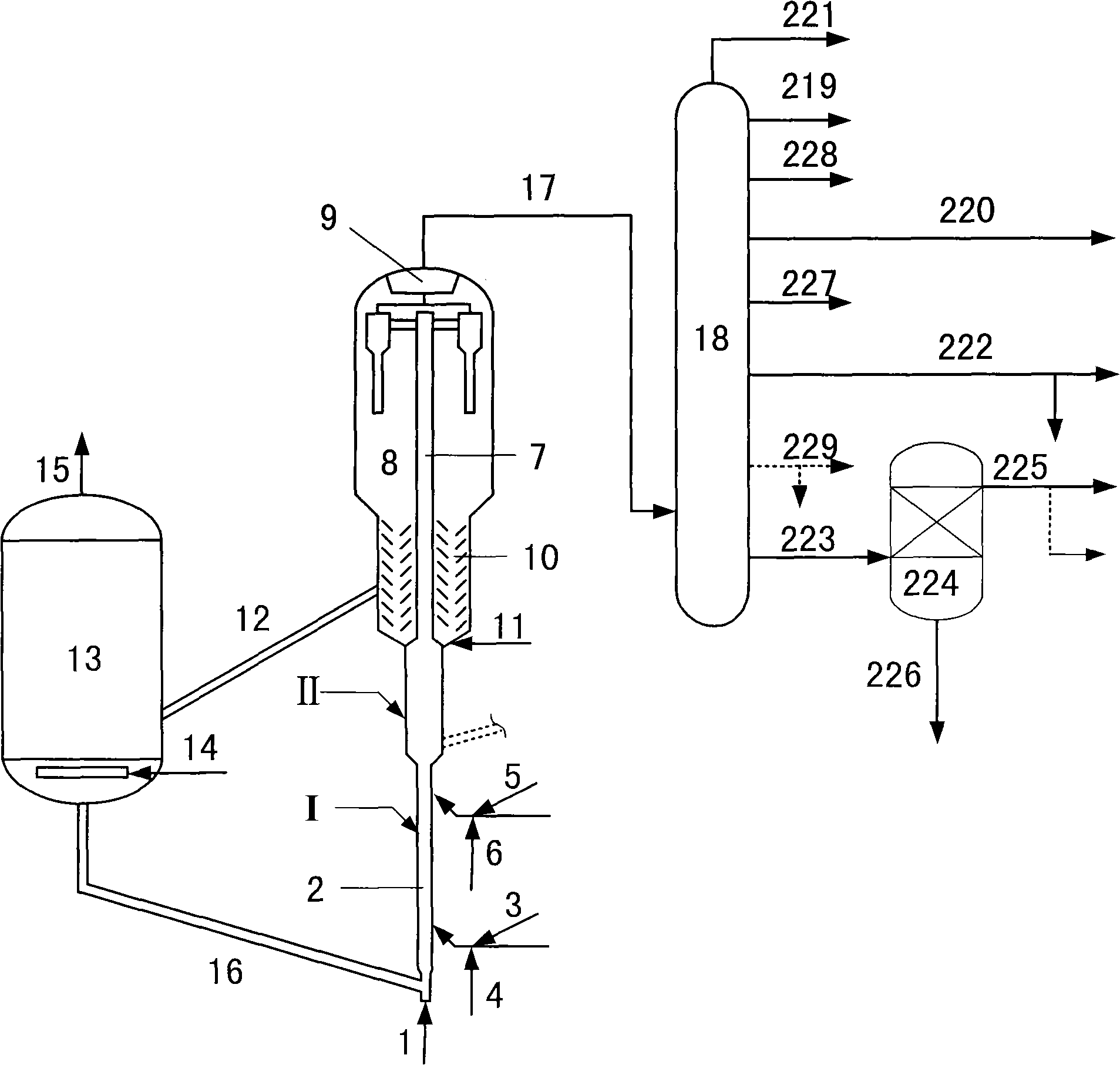

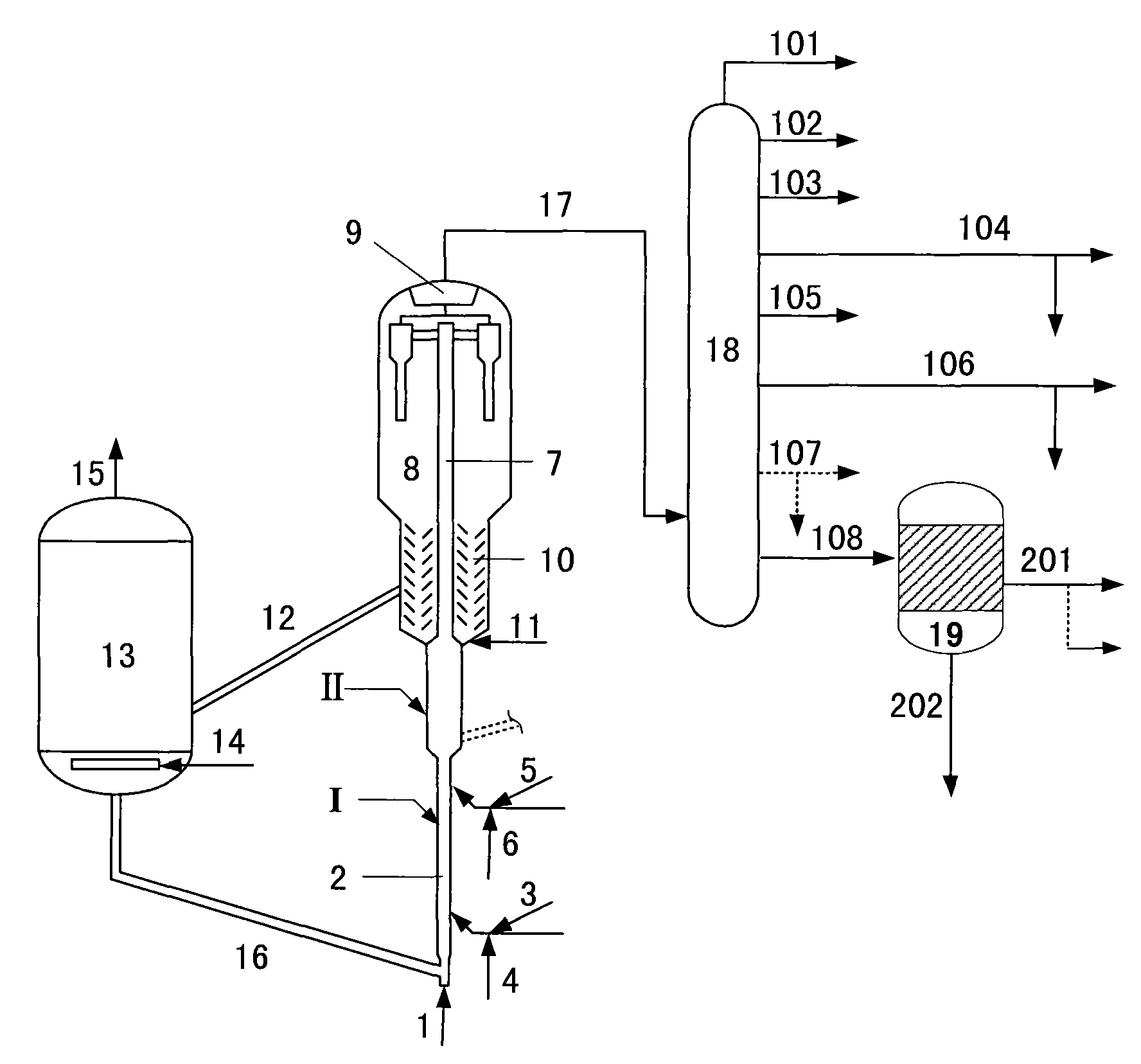

Catalytic conversion method for preparing propylene and high-octane gasoline with crude oil

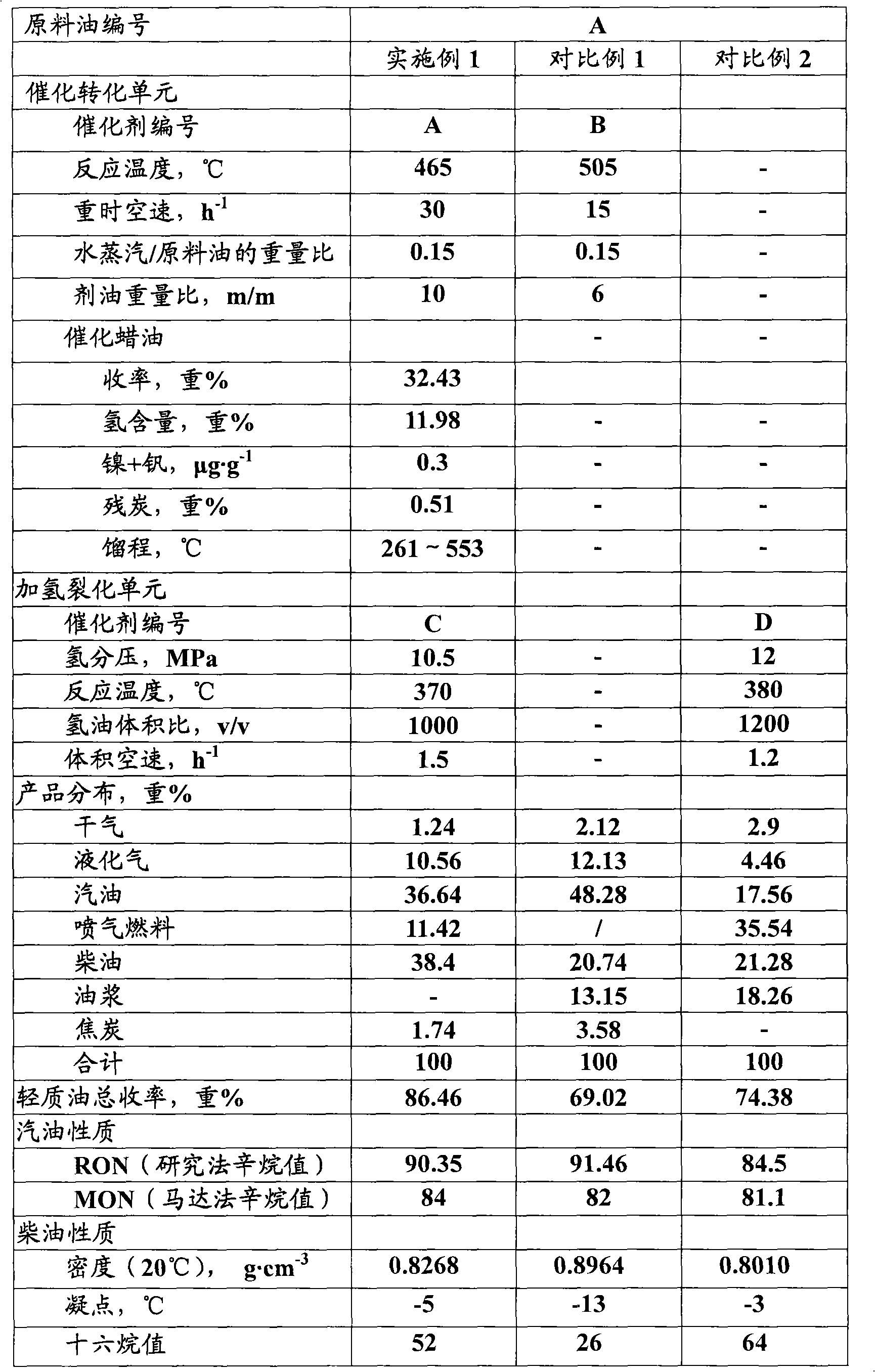

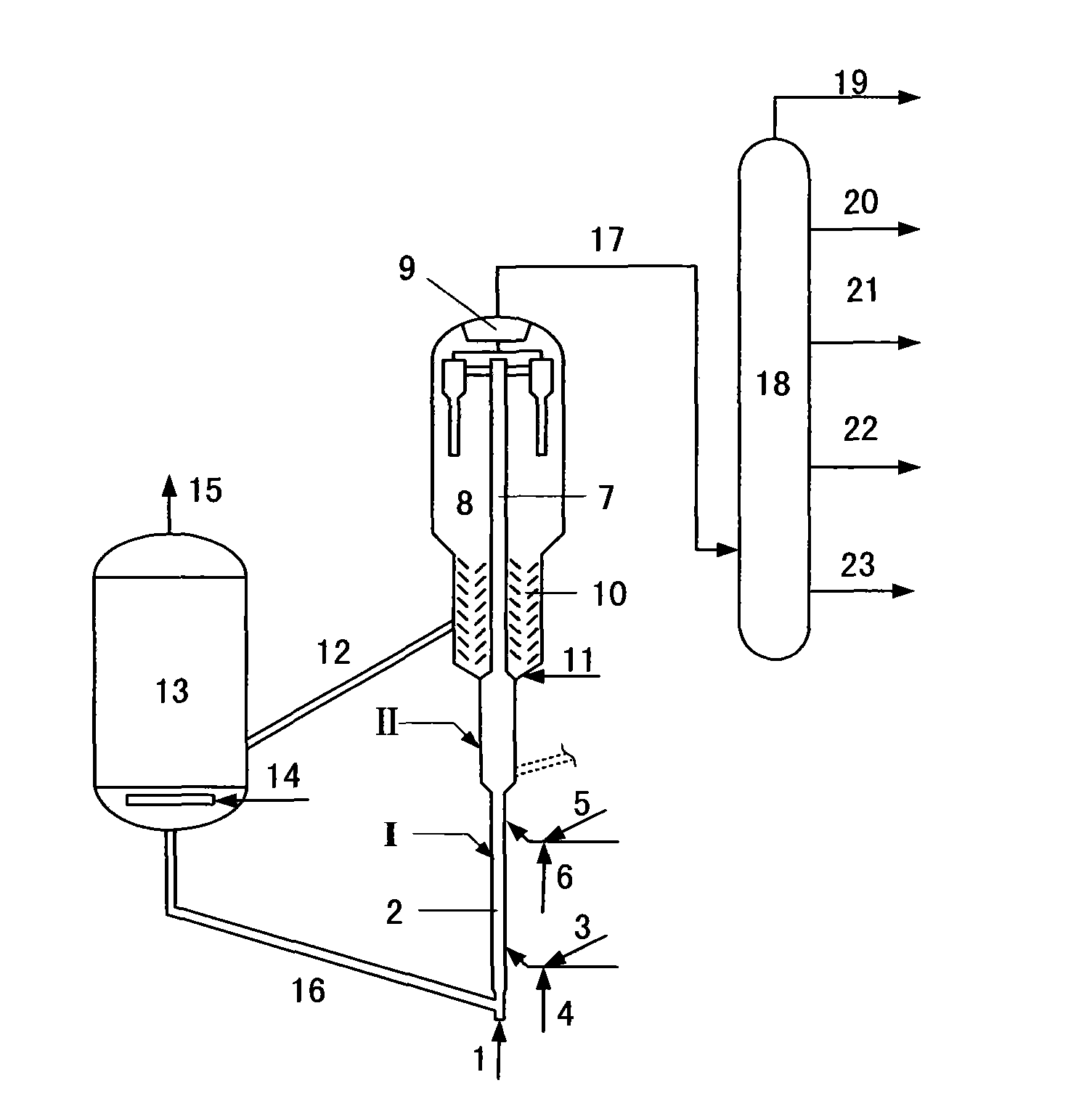

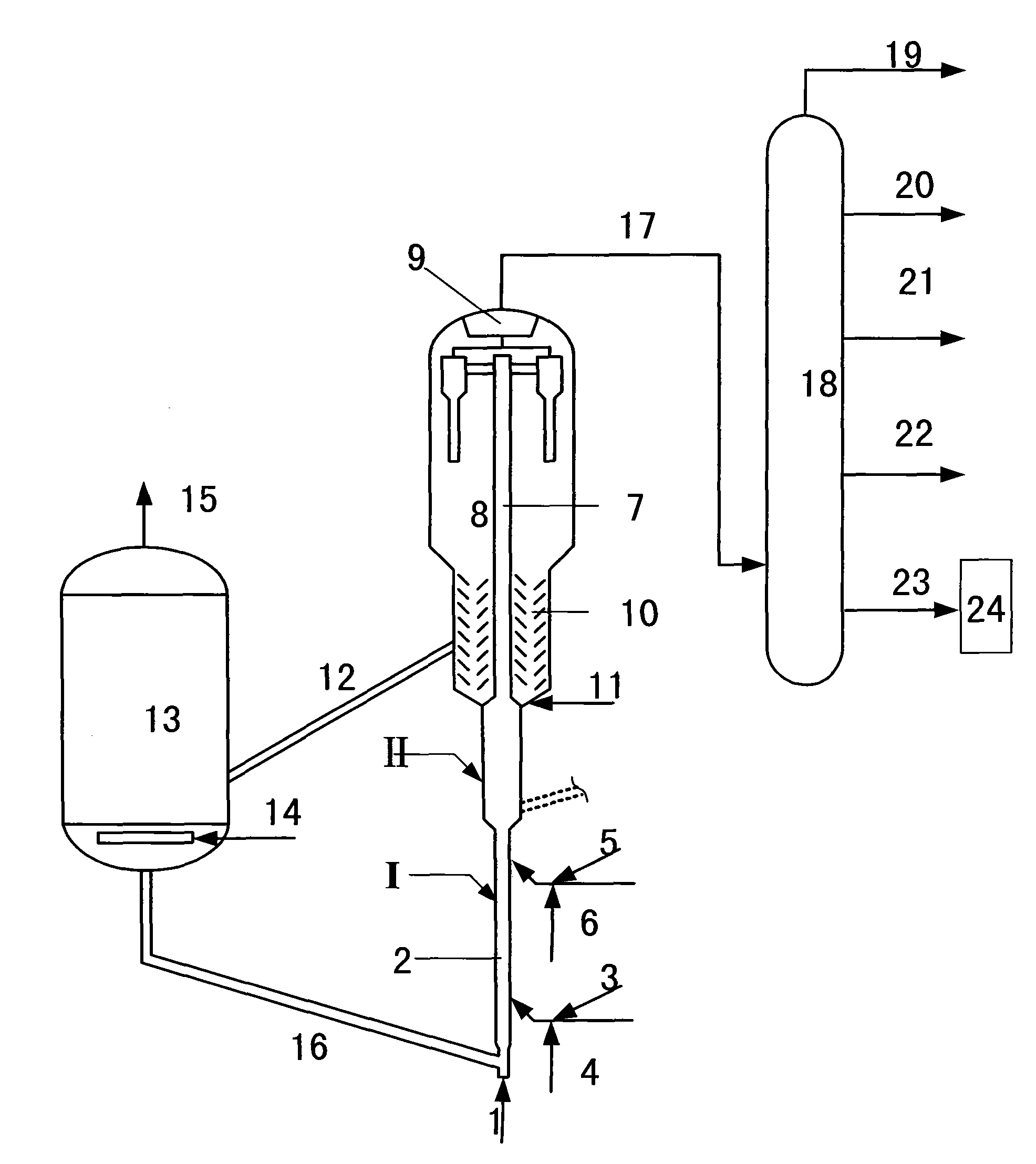

ActiveCN102134509ALess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyWaxReaction temperature

The invention relates to a catalytic conversion method for preparing propylene and high-octane gasolinel with crude oil. The method comprises the following steps: using pretreated crude oil as raw oil, and contacting and carrying out reaction on the pretreated crude oil and catalyst rich in mesopore zeolite in a catalytic conversion reactor; and obtaining the reaction product comprising catalytic wax oil the weight of which accounts for 12 to 60 percent of that of the raw oil after reaction due to the reaction temperature, the residence time of oil gas and the weight ratio of the catalyst to the raw oil, wherein the weight hourly space velocity ranges from 25 to 100 h-1, the reaction temperature ranges from 450 to 700 DEG C, and the weight ratio of the catalyst to the raw oil ranges from 1 to 30. The method converts inferior crude oil into the propylene and the high-octane gasoline, and greatly reduces the yield of dry gas and coke, thus realizing the efficient utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of crangon affinis meat

InactiveCN107836665AImprove nutritional structureGood nutritionLipidic food ingredientsNatural extract food ingredientsCelluloseAdditive ingredient

The invention belongs to the field of processing of aquatic products, and relates to a processing method of crangon affinis meat. The processing method comprises the following steps of performing vacuum deep-frying on pretreated crangon affinis meat, wherein the vacuum deep-frying temperature is 80-120 DEG C, the deep-frying time is 6-10min, the negative pressure of vacuum degree is 0.098-0.08MPa,and the pretreatment of the crangon affinis meat comprises the following steps of sequentially performing low-temperature rinsing on crangon affinis, removing heads, shells and intestinal glands, cutting apart backs, keeping tails, performing low-temperature rinsing, performing soaking in salt water, performing pre-cooking, performing powder pre-wrapping, performing pulp wrapping, performing bread crumb wrapping and performing cold storage. In the pulp pre-wrapping process of the crangon affinis meat, ingredients are in reasonable compatibility, so that pre-wrapped pulp is rich in high cellulose, multivitamins and trace elements, the pre-wrapped pulp is better matched with the crangon affinis meat to obtain more nutrition, and the nutritive structure of deep-fried foods can be improved; and then through pre-cooking, powder pre-wrapping, pulp wrapping, cold storage and deep-frying, the running off of nutrient substances can be greatly reduced, detrimental effects of microorganisms andenzymes can also be restrained, and the original fragrance, the original nutrition and the original meat quality are sufficiently maintained.

Owner:舟山达康科技有限公司

Catalyst conversion method for producing high-octane gasoline by using crude oil

ActiveCN102108308ALess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyWaxPetroleum

The invention provides a catalytic conversion method for producing high-octane gasoline by using crude oil, which comprises: contacting pretreated crude oil serving as raw material oil with a catalyst which contains macroporous zeolite and is distributed according to a coarse particle size in a catalytic conversion reactor to perform a reaction according to reaction temperature, oil gas dwell time and catalyst to raw material oil weight ratio, which are proper enough to enable the reaction to obtain a reaction product containing catalytic wax oil which accounts for 15 to 60 percent of the weight of the raw material oil, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 600 DEG C, and he weight ratio of the catalyst to the raw material oil is 1 to 30. In the method, while low-quality crude oil is converted into high-octane gasoline, the dry gas and coke yields are reduced considerably, the high-efficient utilization of oil resources is realized, and the higher particle uniformity of the catalyst makes the local temperature distribution in a regeneration process more uniform and the breakage orientation of the catalyst lowered correspondingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

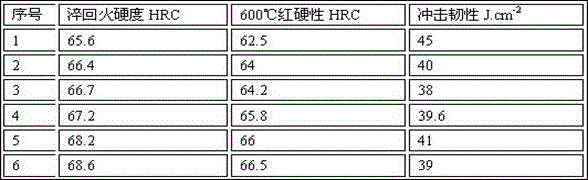

High-toughness and high-red-hardness high-speed tool steel

The invention discloses a high-toughness and high-red-hardness high-speed tool steel which is characterized by comprising the following components by weight percent: 1.2-1.5% of C, 0.2-0.6% of Si, 4.5-5.5% of Cr, 3.5-4.0% of Mo, 0.8-1.5% of V, 1.5-4.5% of W, 0.2-0.8% of Mn, 0.08-1.0% of Zr, 0.1-0.7% of Al, 0.15-1.5% of Re, 0.02-0.1% of N, less than 0.015% of S, less than 0.03% of P and the balance of Fe and trace impurity elements. The high-toughness and high-red-hardness high-speed tool steel has the red hardness and toughness reaching M42 index and does not contain noble element Co; the cost of the high-toughness and high-red-hardness high-speed tool steel is close to that of M2 high-speed steel, but the performances of the high-toughness and high-red-hardness high-speed tool steel are superior to those of the M2 high-speed steel, so that the high-toughness and high-red-hardness high-speed tool steel can be used for replacing M2 and M42 high-speed steel to manufacture high-precision tools and moulds.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

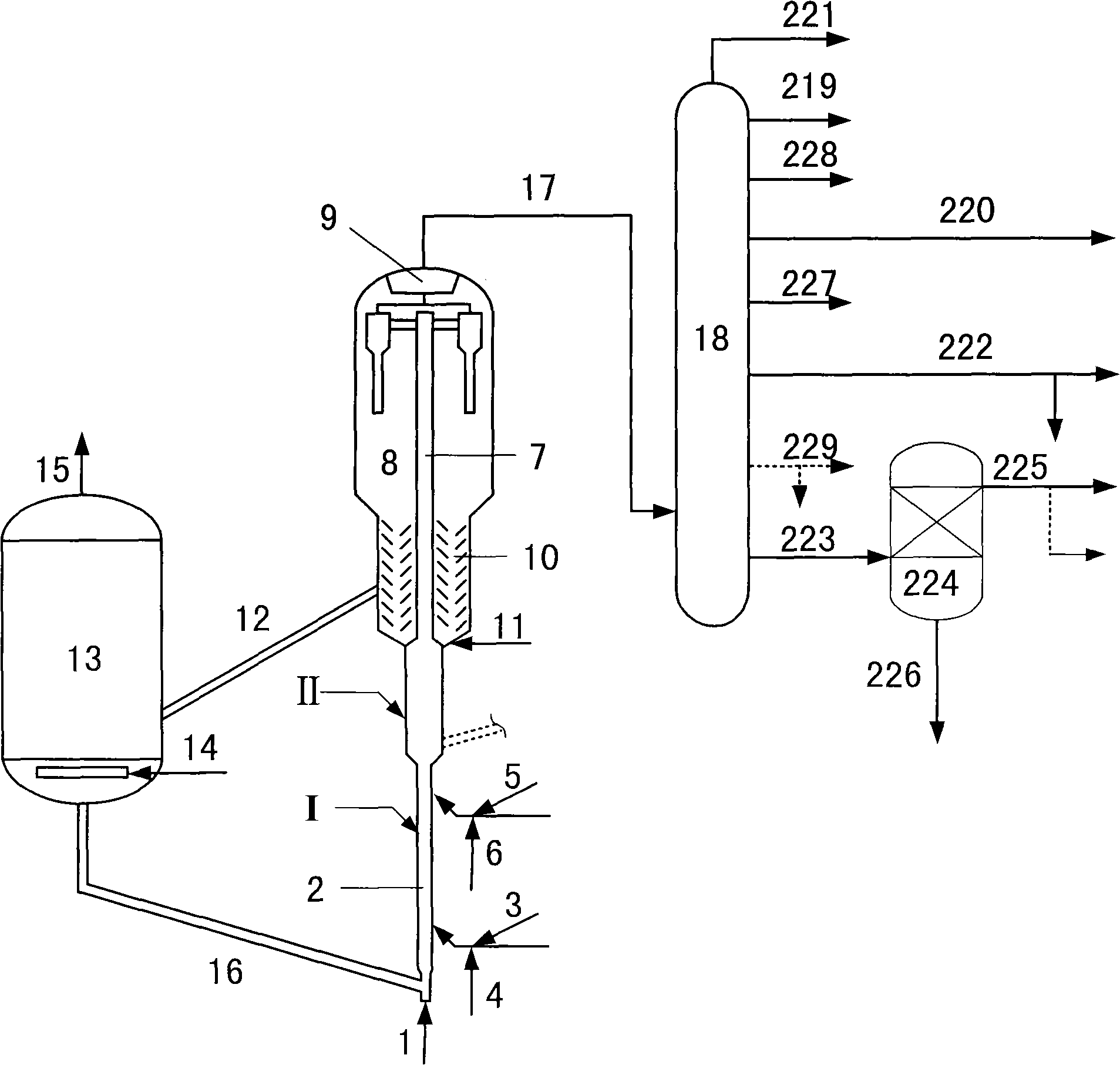

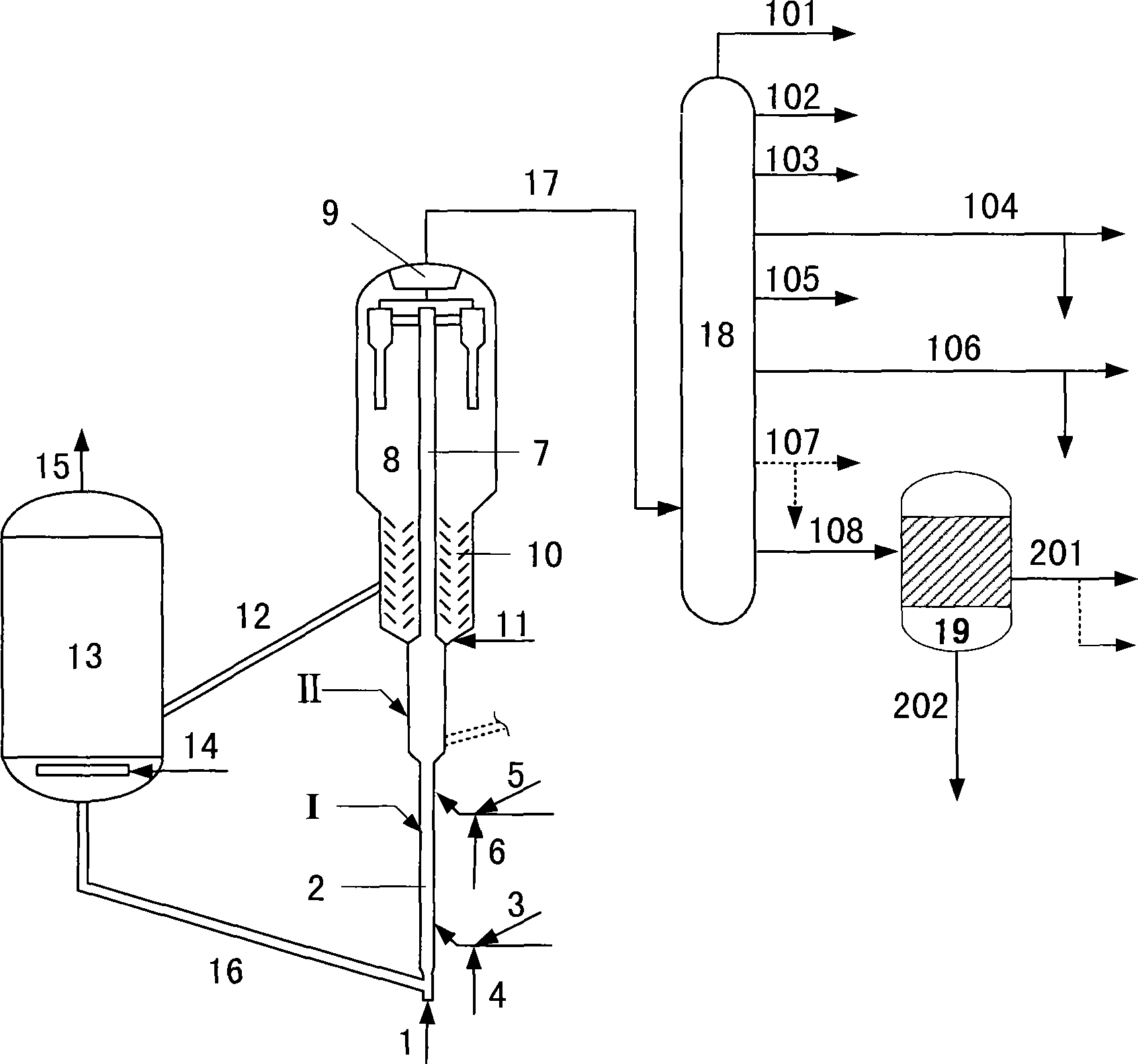

Catalytic conversion method for producing high-quality light fuels from crude oil

ActiveCN102079996ALess investmentReduce corrosion costsTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention discloses a catalytic conversion method for producing high-quality light fuels from crude oil. The crude oil contacts and reacts with a catalyst which is rich in mesoporous zeolite and in coarse particle size distribution. The catalytic conversion method is characterized in that a reaction product containing catalytic wax oil which accounts for 12-60 wt% of the weight of raw material is obtained by the reaction temperature, weight hourly space velocity and the weight ratio of raw oil to catalyst, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100 hours<-1>, the weight ratio of catalyst to raw oil is 1 to 30, and the wax is catalyzed before hydrocracks. In the invention, crude oil catalytic converter and hydrocracking methods are provided, which, in particular, reduces dry gas and coke yield significantly while converting the poor quality of crude oil into high octane gasoline and high-cetane diesel fuel so as to achieve efficient use of oil resources, and reduce the broken tendency of the catalyst and the catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

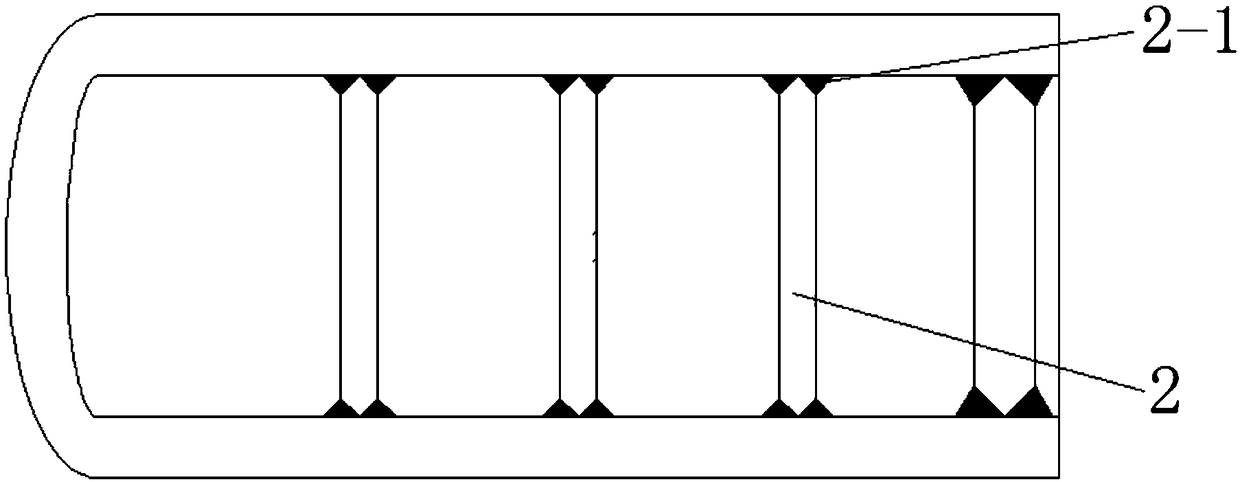

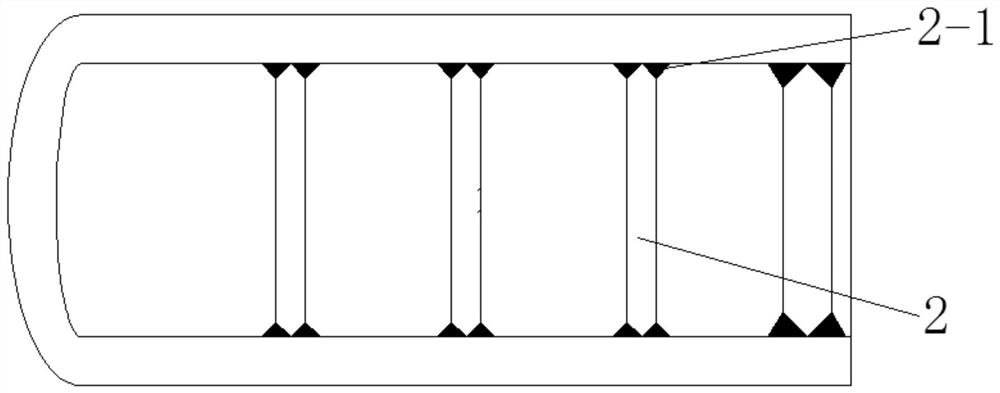

Welding structure of metal defect digging-patching welding groove of steel casting and reinforcing method of welding structure

ActiveCN109014648AImprove thermal field distributionInhibition of harmful effectsWorkpiece edge portionsWelding apparatusStructural stabilityPropagation rate

The invention relates to a welding structure of a metal defect digging-patching welding groove of a steel casting and a reinforcing method of the welding structure. By adoption of the welding structure of the metal defect digging-patching welding groove of the steel casting and the reinforcing method of the welding structure, the technical problems that during digging-patching welding of an existing large cast steel component, deformation of a welding structure is difficult to control, a repair welding area is likely to crack, and the structural stability and fatigue resistance of the weldingstructure cannot be guaranteed easily can be solved. The reinforcing method comprises the steps of first, welding a shell structure; second, arranging a plurality of rows and columns of multi-stage internal steel webs at intervals in the longitudinal and horizontal directions of a weld joint and the depth direction of the groove; third, filling welding deposited metal in a separated space of the welding groove; and fourth, conducting facing welding on the surface of the welding groove. According to the reinforcing method, a shell and rigid framework three-dimensional welding structural systemconstructed through welding can resist and disperse the shrinkage stress of weld joint metal, the welding deformation is effectively controlled, the stability of the welding structure is improved, propagation of fatigue cracks is changed, and accordingly, the propagation rate of the cracks is decreased.

Owner:哈尔滨中正焊接技术开发有限公司 +6

Machining process of burdock fried food

InactiveCN103478640BReduce lossesInhibition of harmful effectsFood dryingFood preparationBiotechnologyMicroorganism

The invention relates to a processing technology of burdock fried food, which is fried or baked into burdock slices in a vacuum and low temperature to obtain fried burdock chips, which greatly reduces the loss of natural pigments and aromatic substances, and inhibits microorganisms and enzymes. The harmful effects of the food, fully maintain the original color and fragrance, and solve the unsafe hidden dangers brought by traditional high-temperature frying to people's health.

Owner:乔子凌

Oxidation and discoloration resistant silver alloy composite material

The invention provides an oxidation and discoloration resistant silver alloy composite material. The silver alloy composite material comprises the following components in percentage by weight: 87%-93% of silver, 0.5%-2% of tin, 1%-2.2% of zinc, 0.5%-3% of vanadium, 2%-5% of manganese, 1.5%-3.5% of ruthenium, and 0.6%-3.1% of indium. According to the invention, as tin, zinc, vanadium, manganese, ruthenium and indium are added into the silver alloy, the silver alloy is improved on the aspect of the oxidation and discoloration resistance, and is applied more widely.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Catalytic conversion method for producing high-quality light fuel by using crude oil

ActiveCN102079995ALess investmentReduce corrosion costsCatalytic crackingTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention relates to a catalytic conversion method for producing a high-quality light fuel by using crude oil, wherein the crude oil comes into contact with a catalyst rich in mesopore zeolite in a reactor to react. The catalytic conversion method is characterized in that a reaction temperature, a weight hourly space velocity and the weight ratio of the catalyst to the crude oil are sufficient for ensuring that a reaction product containing catalytic wax oil accounting for 12-60 wt% of the crude oil is obtained by reaction, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100h-1, and the weight ratio of the catalyst to the crude oil is 1-30; and then the catalytic crude oil is hydrogenated for cracking. The invention provides a method combining crude oil catalytic conversion with hydrogenation cracking, and especially, when poor-quality crude oil is converted to high-octane gasoline and high-hexadecane value of diesel oil, the yields of dry gas and coke are greatly reduced so that high-efficiency utilization of petroleum resources is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation technology of anti-oxidation discoloration silver alloy

The invention belongs to the field of alloy, and provides a preparation process for oxidation and discoloration resistant silver alloy. The process specifically comprises the following steps: 1, preparing material; 2, heating and melting silver, tin and ruthenium in a vacuum melting furnace to prepare into a silver-tin-ruthenium ternary alloy solution; 3, taking respectively adding zinc, vanadium, manganese and indium weighed in parts into the taken ternary alloy solution under normal pressure, uniformly mixing and stirring, and performing heat preservation; 4, adding the intermediate alloy solution obtained in the step 3 into the residual ternary alloy solution in the step 2 to obtain a final silver alloy solution, and cooling under normal pressure and forming to obtain a silver alloy block. The silver alloy provided by the invention is good in oxidation and discoloration resistance the melting point of the silver alloy can be reduced, mechanical performance and processing performance of the alloy can be improved, the situation that the alloy is hard can be improved, and the silver alloy is corrosion resistant and oxidation resistant.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

A kind of nickel-based welding rod and preparation method thereof

ActiveCN109454357BGrain refinementInhibition of harmful effectsWelding/cutting media/materialsSoldering mediaIron powderChemical composition

Owner:DONGGUAN UNIV OF TECH

Catalytic conversion method for preparing propylene and high-octane gasoline with crude oil

ActiveCN102134509BLess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyWaxReaction temperature

The invention relates to a catalytic conversion method for preparing propylene and high-octane gasolinel with crude oil. The method comprises the following steps: using pretreated crude oil as raw oil, and contacting and carrying out reaction on the pretreated crude oil and catalyst rich in mesopore zeolite in a catalytic conversion reactor; and obtaining the reaction product comprising catalytic wax oil the weight of which accounts for 12 to 60 percent of that of the raw oil after reaction due to the reaction temperature, the residence time of oil gas and the weight ratio of the catalyst to the raw oil, wherein the weight hourly space velocity ranges from 25 to 100 h-1, the reaction temperature ranges from 450 to 700 DEG C, and the weight ratio of the catalyst to the raw oil ranges from 1 to 30. The method converts inferior crude oil into the propylene and the high-octane gasoline, and greatly reduces the yield of dry gas and coke, thus realizing the efficient utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

An anti-oxidation discoloration silver alloy composite material

The invention provides an oxidation and discoloration resistant silver alloy composite material. The silver alloy composite material comprises the following components in percentage by weight: 87%-93% of silver, 0.5%-2% of tin, 1%-2.2% of zinc, 0.5%-3% of vanadium, 2%-5% of manganese, 1.5%-3.5% of ruthenium, and 0.6%-3.1% of indium. According to the invention, as tin, zinc, vanadium, manganese, ruthenium and indium are added into the silver alloy, the silver alloy is improved on the aspect of the oxidation and discoloration resistance, and is applied more widely.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

High stress corrosion resistance al-zn-mg-cu aluminum alloy profiles and preparation method thereof

Owner:广西南南铝加工有限公司

Catalytic conversion method for producing high-quality light fuel by using crude oil

ActiveCN102079995BLess investmentReduce corrosion costsCatalytic crackingTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention relates to a catalytic conversion method for producing a high-quality light fuel by using crude oil, wherein the crude oil comes into contact with a catalyst rich in mesopore zeolite in a reactor to react. The catalytic conversion method is characterized in that a reaction temperature, a weight hourly space velocity and the weight ratio of the catalyst to the crude oil are sufficient for ensuring that a reaction product containing catalytic wax oil accounting for 12-60 wt% of the crude oil is obtained by reaction, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100h-1, and the weight ratio of the catalyst to the crude oil is 1-30; and then the catalytic crude oil is hydrogenated for cracking. The invention provides a method combining crude oil catalytic conversion with hydrogenation cracking, and especially, when poor-quality crude oil is converted to high-octane gasoline and high-hexadecane value of diesel oil, the yields of dry gas and coke are greatly reduced so that high-efficiency utilization of petroleum resources is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for production of propylene and high-octane-value gasoline by crude oil

ActiveCN102134510BLess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyReaction temperaturePetroleum

The invention discloses a catalytic conversion method for production of propylene and high-octane-value gasoline by crude oil, which is characterized in that: pretreated crude oil is used as raw oil and comes into contact with a catalyst, featured by rich mesopore zeolite and coarse particle diameter distribution, in a catalytic conversion reactor, reaction temperature, oil gas residence time and the weight ratio of the catalyst to the raw oil guarantee that the reaction results in a reaction product containing catalytic wax oil accounting for 12 to 60% of the raw oil by weight, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 700 DEG C and the weight ratio of the catalyst to the raw oil is 1 to 30. The method achieves the conversion of low-quality crude oil into propylene and high-octane-value gasoline and simultaneously reduces the yield of dry gas and coke remarkably so as to realize the effective utilization of petroleum resources; and local temperature distribution is more uniform in the process of regeneration owing to more homogeneous particles of the catalyst, and the crushing tendency of the catalyst is correspondingly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Welding Structure and Reinforcing Method of Metal Defect Digging and Repairing Welding Groove of Steel Castings

ActiveCN109014648BImprove thermal field distributionChange stress conditionsWorkpiece edge portionsWelding apparatusWeld seamDeformation control

The invention relates to a welding structure of a metal defect digging-patching welding groove of a steel casting and a reinforcing method of the welding structure. By adoption of the welding structure of the metal defect digging-patching welding groove of the steel casting and the reinforcing method of the welding structure, the technical problems that during digging-patching welding of an existing large cast steel component, deformation of a welding structure is difficult to control, a repair welding area is likely to crack, and the structural stability and fatigue resistance of the weldingstructure cannot be guaranteed easily can be solved. The reinforcing method comprises the steps of first, welding a shell structure; second, arranging a plurality of rows and columns of multi-stage internal steel webs at intervals in the longitudinal and horizontal directions of a weld joint and the depth direction of the groove; third, filling welding deposited metal in a separated space of the welding groove; and fourth, conducting facing welding on the surface of the welding groove. According to the reinforcing method, a shell and rigid framework three-dimensional welding structural systemconstructed through welding can resist and disperse the shrinkage stress of weld joint metal, the welding deformation is effectively controlled, the stability of the welding structure is improved, propagation of fatigue cracks is changed, and accordingly, the propagation rate of the cracks is decreased.

Owner:哈尔滨中正焊接技术开发有限公司 +6

Method for processing crude oil with high acid value

ActiveCN100363467CEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-octane petrol from crude oil

InactiveCN102108309ALess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyReaction temperaturePetroleum

The invention discloses a catalytic conversion method for producing high-octane petrol from crude oil. The catalytic conversion method comprises the following step of: blending and reacting pretreated crude oil serving as raw material oil and a large pore zeolite-containing catalyst in a catalytic conversion reactor, wherein a reaction temperature, an oil gas retention time and a weight ratio of the catalyst to the raw material oil are enough to obtain a reaction product which contains catalytic wax oil which accounts for 15 percent to 60 percent of the raw material oil; the weight houly space velocity is 25 to 100 hour <-1>; the reaction temperature is between 450 and 600 DEG C; and the weight ratio of the catalyst to the raw material oil is 1 to 30. While inferior crude oil is conversed into high-octane petrol by the method, the production rate of dry gas and coke is highly reduced, so that highly effective utilization of an oil resource is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst conversion method for producing high-octane gasoline by using crude oil

ActiveCN102108308BLess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyReaction temperaturePetroleum

The invention provides a catalytic conversion method for producing high-octane gasoline by using crude oil, which comprises: contacting pretreated crude oil serving as raw material oil with a catalyst which contains macroporous zeolite and is distributed according to a coarse particle size in a catalytic conversion reactor to perform a reaction according to reaction temperature, oil gas dwell time and catalyst to raw material oil weight ratio, which are proper enough to enable the reaction to obtain a reaction product containing catalytic wax oil which accounts for 15 to 60 percent of the weight of the raw material oil, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 600 DEG C, and he weight ratio of the catalyst to the raw material oil is 1 to 30. In the method, while low-quality crude oil is converted into high-octane gasoline, the dry gas and coke yields are reduced considerably, the high-efficient utilization of oil resources is realized, and the higher particle uniformity of the catalyst makes the local temperature distribution in a regeneration process more uniform and the breakage orientation of the catalyst lowered correspondingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-quality light fuels from crude oil

ActiveCN102079996BLess investmentReduce corrosion costsTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention discloses a catalytic conversion method for producing high-quality light fuels from crude oil. The crude oil contacts and reacts with a catalyst which is rich in mesoporous zeolite and in coarse particle size distribution. The catalytic conversion method is characterized in that a reaction product containing catalytic wax oil which accounts for 12-60 wt% of the weight of raw material is obtained by the reaction temperature, weight hourly space velocity and the weight ratio of raw oil to catalyst, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100 hours<-1>, the weight ratio of catalyst to raw oil is 1 to 30, and the wax is catalyzed before hydrocracks. In the invention, crude oil catalytic converter and hydrocracking methods are provided, which, in particular, reduces dry gas and coke yield significantly while converting the poor quality of crude oil into high octane gasoline and high-cetane diesel fuel so as to achieve efficient use of oil resources, and reduce the broken tendency of the catalyst and the catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com