Nickel-based welding rod and preparation method thereof

A nickel-based welding rod and welding core technology, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of unfavorable development of offshore oil and gas industry, difficult quality control, long procurement cycle, etc., to increase the available length and increase the metal The effect of deposition amount and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

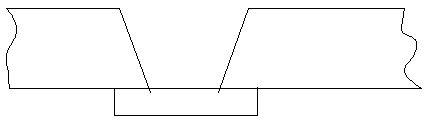

Image

Examples

Embodiment 1

[0035] After smelting, pouring and drawing, the diameter of the welding core is Ф4mm. After mixing the powder according to the designed formula, carry out dry powder mixing and wet powder mixing, and then press the welding rod with a hydraulic press. After high-temperature drying, an electrode with a coated outer diameter of Ф6.5mm is formed.

[0036] The chemical composition of the welding core, by weight percentage: C≤0.2%, Mn2%, Si0.6-1.8%, Cr15-20%, Al≤0.2%, Ti≤0.3%, W2-6%, S≤0.005% , P≤0.006%, the balance is Ni; the composition of the drug core is calculated according to its weight percentage: marble 20-30%, fluorite 30-45%, quartz 8-12%, rutile 2-7%, titanium dioxide 1-2 %, ferro-vanadium 2-6%, ferro-manganese 2-6%, ferro-tungsten 4-7%, and iron powder as the balance.

[0037] After the welding is completed, a tensile sample of the deposited metal is prepared. The tensile strength is 750Mpa, the elongation is 34%, and the impact energy at -196°C is 88J for welding hot c...

Embodiment 2

[0040] After smelting, pouring and drawing, the diameter of the welding core is Ф4mm. After mixing the powder according to the designed formula, carry out dry powder mixing and wet powder mixing, and then press the welding rod with a hydraulic press. After high-temperature drying, an electrode with a coated outer diameter of Ф6.5mm is formed.

[0041] The chemical composition of the welding core, by weight percentage: C≤0.2%, Mn2%, Si0.6-1.3%, Cr15-18%, Al≤0.2%, Ti≤0.3%, W2-4%, S≤0.005% , P≤0.006%, the balance is Ni; the composition of the drug core is calculated according to its weight percentage: marble 20-30%, fluorite 30-45%, quartz 8-12%, rutile 3-7%, titanium dioxide 4-5% %, ferro-vanadium 2-6%, ferro-manganese 2-6%, ferro-tungsten 4-7%, and iron powder as the balance.

[0042] After the welding is completed, a tensile sample of the deposited metal is prepared. The tensile strength is 756Mpa, the elongation is 32%, and the impact energy at -196°C is 76J for welding hot ...

Embodiment 3

[0045] A preparation method of flux cored wire:

[0046] After smelting, pouring and drawing, the diameter of the welding core is Ф4mm. After mixing the powder according to the designed formula, carry out dry powder mixing and wet powder mixing, and then press the welding rod with a hydraulic press. After high-temperature drying, an electrode with a coated outer diameter of Ф6.5mm is formed.

[0047] The chemical composition of the welding core, by weight percentage: C≤0.2%, Mn5%, Si0.6-1.3%, Cr18-20%, Al≤0.2%, Ti≤0.3%, W6-8%, S≤0.005% , P≤0.006%, the balance is Ni; the composition of the drug core is calculated according to its weight percentage: marble 20-30%, fluorite 30-45%, quartz 8-12%, rutile 3-7%, titanium dioxide 4-5% %, ferro-vanadium 2-6%, ferro-manganese 2-6%, ferro-tungsten 4-7%, and iron powder as the balance.

[0048] After the welding is completed, a tensile sample of the deposited metal is prepared. The tensile strength is 774Mpa, the elongation is 37%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com