An improved mechanically welded butt joint groove of dissimilar steel pipes

An improved technology for butt joints, applied to the edge of workpieces, metal processing equipment, manufacturing tools, etc., can solve the problems of large amount of corrosion, burst pipes, etc., and achieve the effect of simple groove processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

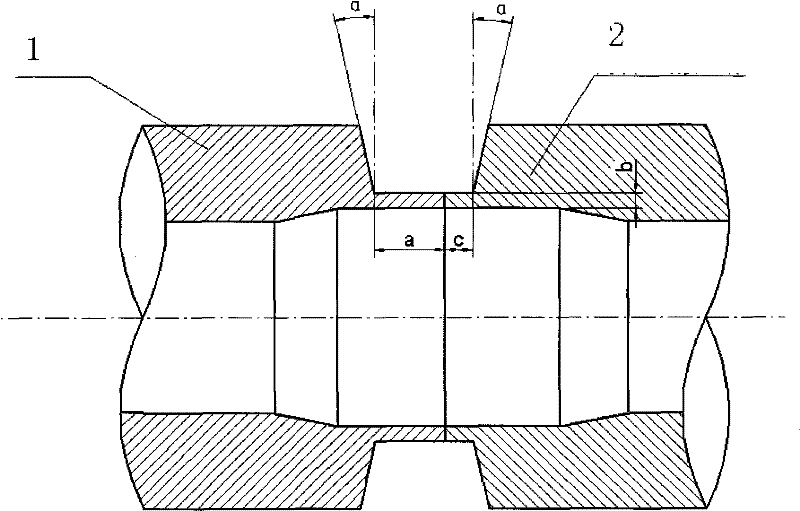

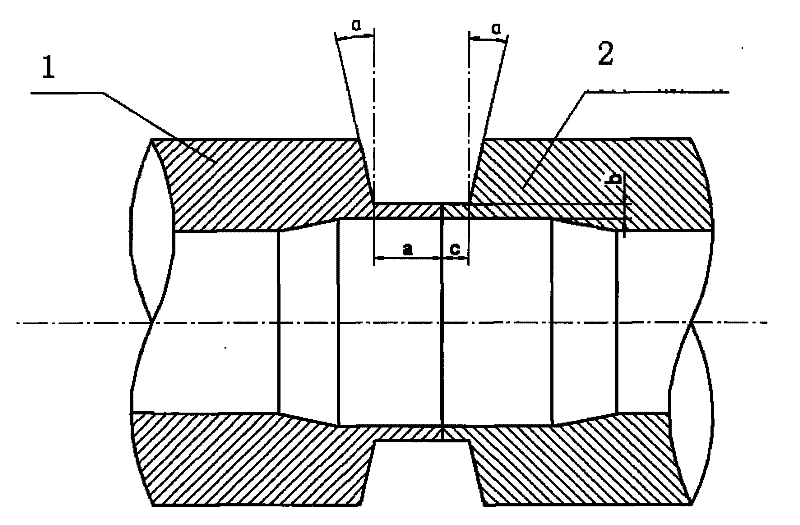

[0011] Such as figure 1 As shown, it is a structural schematic diagram of an improved dissimilar steel pipe mechanically welded butt joint groove provided by the present invention. There is a groove with an angle α on the stainless steel pipe 1 side and the high-alloy heat-resistant steel pipe 2, and on the stainless steel pipe 1 side There is a boss with a length a and a thickness b, and a boss with a length c and a thickness b on the 2 sides of the high-alloy heat-resistant steel pipe, where 0≤c<a. Wherein, the length a is 3.5 mm, the thickness b is 1.5 mm, the length c is 1.5 mm, and the angle α is 7°.

[0012] When implementing the present invention, the asymmetric bevel is firstly machined with a corresponding custom-made tool or a machining lathe. Then mechanical welding is adopted, and before welding, it is confirmed that the surface of the base metal meets the welding requirements, and there is no gap between the counterparts. Finally, certain welding process paramet...

Embodiment 2

[0014] The structure of this embodiment is the same as that of Embodiment 1, except that the length a is 5 mm, the thickness b is 1.4 mm, the length c is 0, and the angle α is 10°.

Embodiment 3

[0016] The structure of this embodiment is the same as that of Embodiment 1, except that the length a is 3 mm, the thickness b is 1 mm, the length c is 2, and the angle α is 5°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com