System and method for additive manufacturing of intersecting metal parts with auxiliary wire filling gmaw arc

A technology for metal parts and additive manufacturing, which is applied in the field of GMAW arc additive manufacturing system for auxiliary wire filling of cross metal parts, can solve the problems of easy cracking and poor mechanical properties of cross parts, so as to increase the amount of deposition and increase Manufacturing efficiency, effect of reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the features and advantages of the present invention more obvious and understandable, the specific examples below are described in detail as follows:

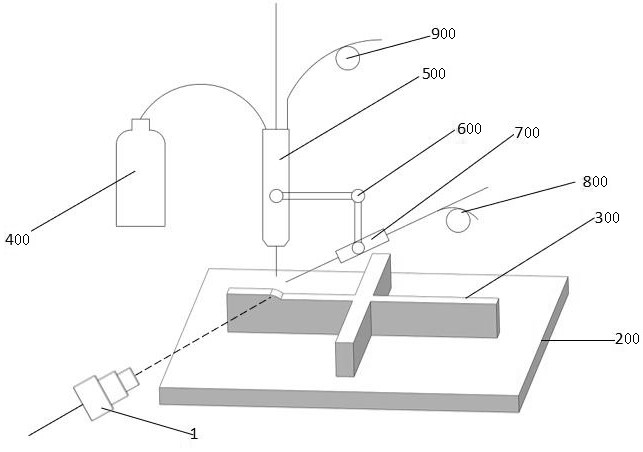

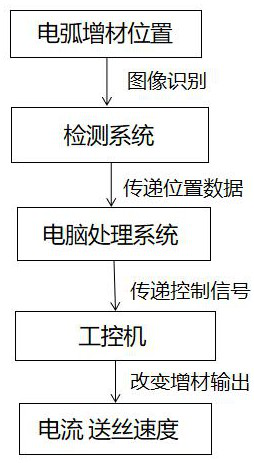

[0043] Such as figure 1 As shown, the device solution provided in this embodiment mainly includes: industrial computer, GMAW arc additive position visual detection and feedback system, melting electrode welding torch 500, auxiliary wire filling device, substrate 200 and composite wire feeding device.

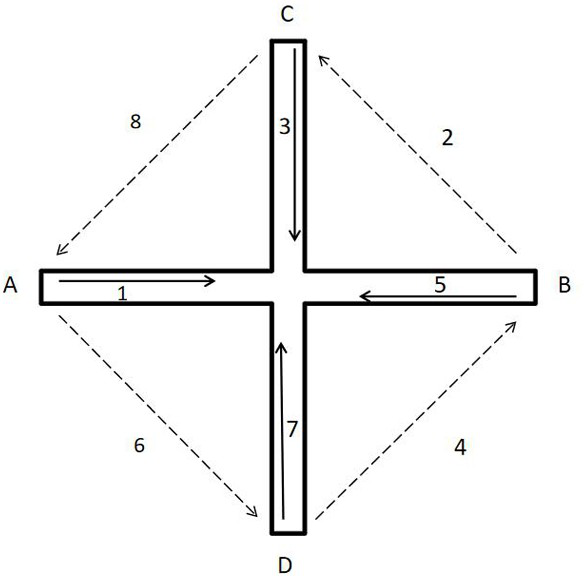

[0044] Among them, the industrial computer is used to generate the path code information of the additive manufacturing part, and control the composite wire feeding device to feed the wire and the melting electrode welding torch 500 on the surface of the substrate 200 according to the path sent by the industrial computer according to the process parameters set during the additive manufacturing of the part Instructions are piled up to form each layer, and the target parts are formed layer by layer, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com