A multi-arc gun additive manufacturing system and method

A technology of additive manufacturing and arc gun, which is applied in the field of multi-arc gun additive manufacturing system, can solve the problems of large residual stress and deformation and low dimensional accuracy of components, and achieve reduced residual stress and deformation, excellent mechanical properties, and molten pool The effect of small size fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

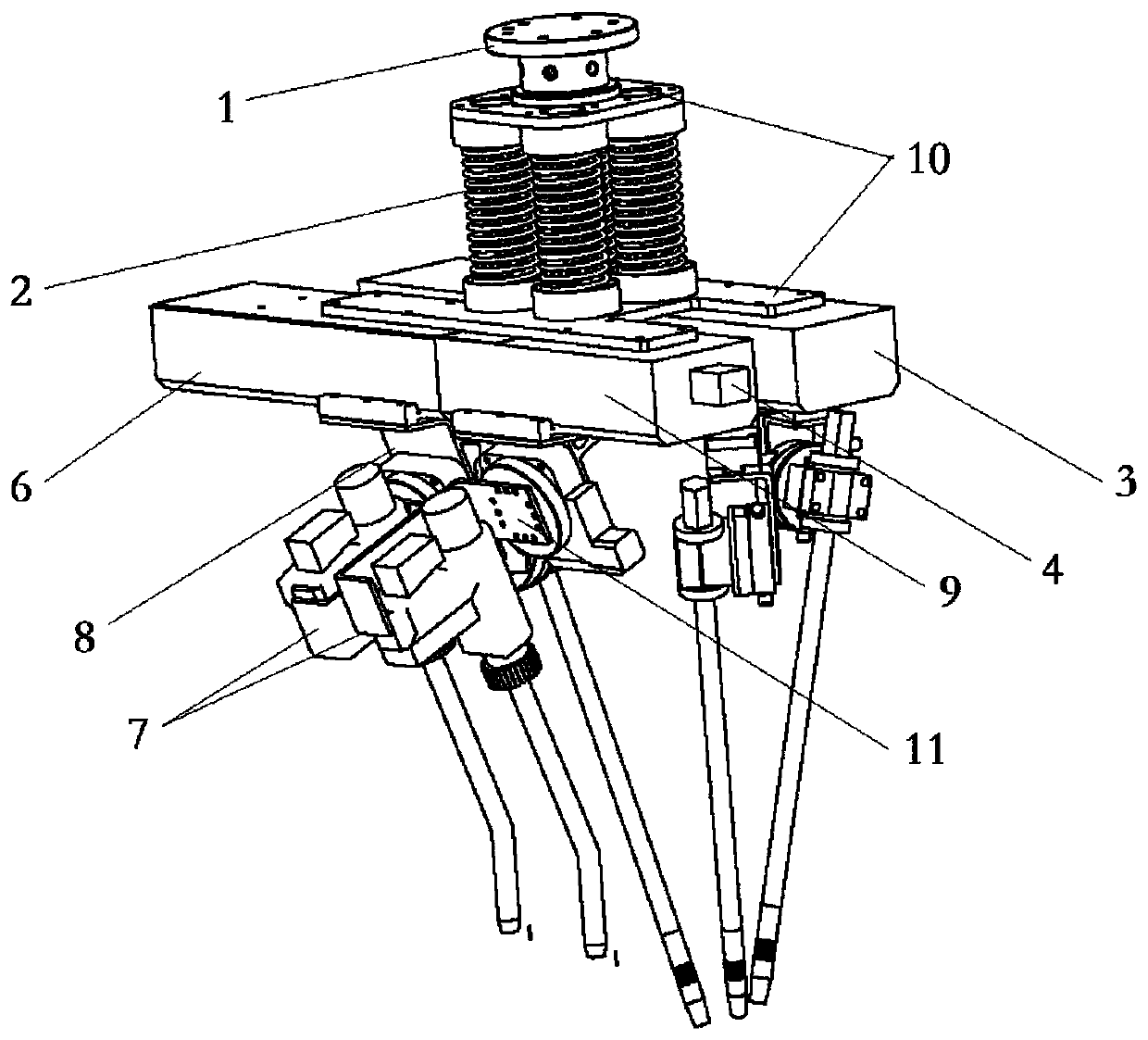

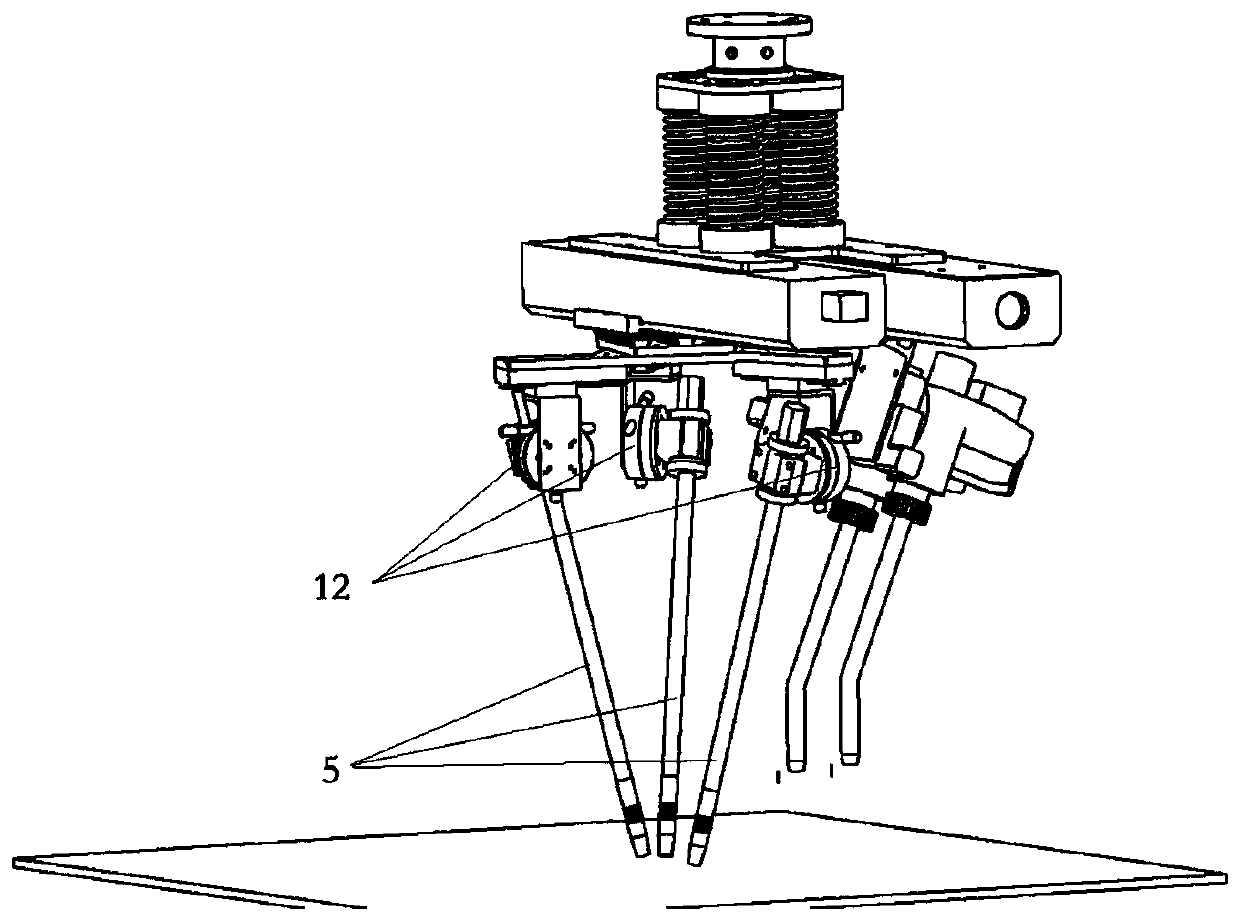

[0048] use as figure 1 In the system shown, the component to be formed is a large ship stern shaft frame component, and the raw material is a metal-type cored wire with a diameter of 1.2mm. The specific steps are as follows:

[0049] The S1 multi-arc torch system is fixed on the KUKA KR60-3 robotic arm, and the Q235B substrate is placed on the horizontal plane;

[0050] S2 Adjust the ball screw slide table so that the distance between the nozzles of the three filling arc welding torches and the nozzles of the two contour arc welding torches on the horizontal plane is 70 mm, adjust the rotating table so that the two contour arc welding torches are perpendicular to the horizontal plane, and the three filling arc welding torches are perpendicular to the horizontal plane. The angle between the welding torch and the horizontal plane is 60° to achieve the best forming effect;

[0051] S3 transmits the corresponding pulse signal to the stepping motor according to the outline of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com