Inductive charging electrostatic adsorption spraying method

A technology of electrostatic adsorption and inductive charging, which is applied in applications, devices for catching or killing insects, animal husbandry, etc. It can solve the problems of poor insecticidal effect, complicated wiring, and weak penetrability, so as to increase the spray effect, The effect of increasing the number of deposits and speeding up the sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

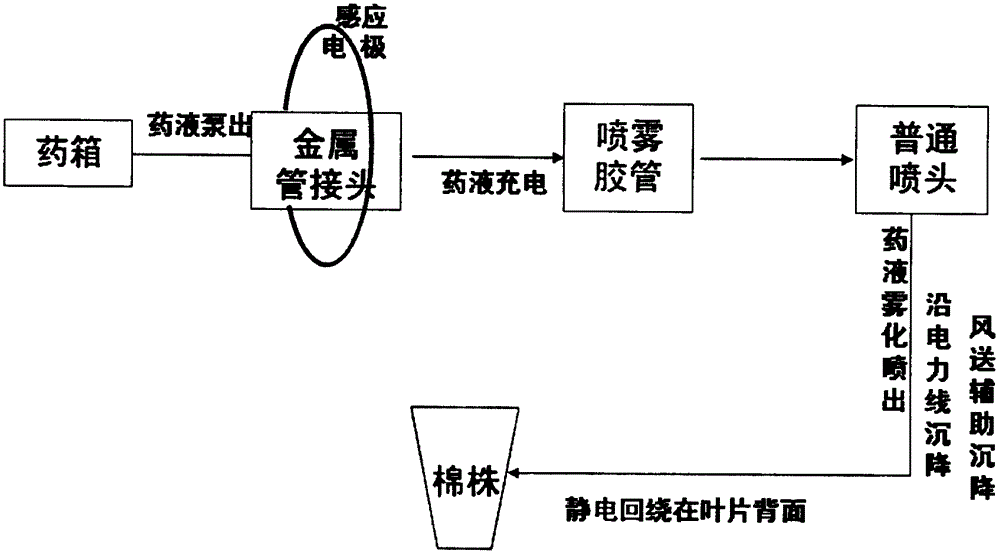

[0014] Embodiment: With reference to accompanying drawing, present embodiment comprises:

[0015] A. Pour the liquid medicine into the medicine box, the medicine liquid is output from the medicine box after being stirred, and enters the infusion hose;

[0016] B. The liquid medicine enters the filter through the infusion hose, and then enters the diaphragm pump through the filter;

[0017] C. The liquid medicine enters the metal pipe joint connected with the diaphragm pump from the diaphragm pump;

[0018] D. There is an induction coil on the metal pipe joint mentioned above. The induction coil is connected to the power supply. The induction coil is generated by the power supply with AC220V±5%, and the output voltage of 50Hz is electrified. It is regulated by the control box and generated by a high-frequency DC high-voltage generator. High-frequency high-voltage direct current energizes the induction coil set at the metal pipe joint;

[0019] E. The liquid medicine is charge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com