A kind of nickel-based welding rod and preparation method thereof

A technology of nickel-based welding rods and welding rods, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of long procurement cycle, high price, and difficult quality control, so as to improve the quality of weld forming, improve mechanical properties, reduce Effect of crystallization crack tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

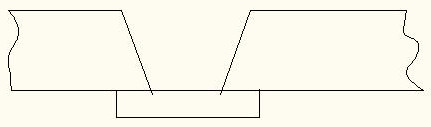

Image

Examples

Embodiment 1

[0035] The diameter of the welding core is Ф4mm obtained by melting, pouring and drawing. After mixing powder according to the designed formula, dry powder stirring and wet powder stirring are carried out, and then the welding rod is pressed by a hydraulic press. The welding rod is dried, dried at low temperature and kept at 350 °C for 2 hours After drying at high temperature, a welding rod with a coating outer diameter of Ф6.5mm is formed.

[0036] The chemical composition of the solder core, by weight percentage: C≤0.2%, Mn2%, Si0.6-1.8%, Cr15-20%, Al≤0.2%, Ti≤0.3%, W2-6%, S≤0.005% , P≤0.006%, the balance is Ni; the composition of the core is based on its weight percentage: marble 20-30%, fluorite 30-45%, quartz 8-12%, rutile 2-7%, titanium dioxide 1-2 %, ferrovanadium 2-6%, ferromanganese 2-6%, ferrotungsten 4-7%, iron powder is the balance.

[0037] After the welding is completed, the deposited metal tensile specimen is prepared, the tensile strength is 750Mpa, the elonga...

Embodiment 2

[0040] The diameter of the welding core is Ф4mm obtained by melting, pouring and drawing. After mixing powder according to the designed formula, dry powder stirring and wet powder stirring are carried out, and then the welding rod is pressed by a hydraulic press. The welding rod is dried, dried at low temperature and kept at 350 °C for 2 hours After drying at high temperature, a welding rod with a coating outer diameter of Ф6.5mm is formed.

[0041] The chemical composition of the solder core, by weight percentage: C≤0.2%, Mn2%, Si0.6-1.3%, Cr15-18%, Al≤0.2%, Ti≤0.3%, W2-4%, S≤0.005% , P≤0.006%, the balance is Ni; the composition of the core is based on its weight percentage: marble 20-30%, fluorite 30-45%, quartz 8-12%, rutile 3-7%, titanium dioxide 4-5 %, ferrovanadium 2-6%, ferromanganese 2-6%, ferrotungsten 4-7%, iron powder is the balance.

[0042] After the welding is completed, the deposited metal tensile specimen is prepared, the tensile strength is 756Mpa, the elonga...

Embodiment 3

[0045] A preparation method of flux-cored welding wire:

[0046] The diameter of the welding core is Ф4mm obtained by melting, pouring and drawing. After mixing powder according to the designed formula, dry powder stirring and wet powder stirring are carried out, and then the welding rod is pressed by a hydraulic press. The welding rod is dried, dried at low temperature and kept at 350 °C for 2 hours After drying at high temperature, a welding rod with a coating outer diameter of Ф6.5mm is formed.

[0047] The chemical composition of the solder core, by weight percentage: C≤0.2%, Mn5%, Si0.6-1.3%, Cr18-20%, Al≤0.2%, Ti≤0.3%, W6-8%, S≤0.005% , P≤0.006%, the balance is Ni; the composition of the core is based on its weight percentage: marble 20-30%, fluorite 30-45%, quartz 8-12%, rutile 3-7%, titanium dioxide 4-5 %, ferrovanadium 2-6%, ferromanganese 2-6%, ferrotungsten 4-7%, iron powder is the balance.

[0048] After the welding is completed, the deposited metal tensile speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com