Welding Structure and Reinforcing Method of Metal Defect Digging and Repairing Welding Groove of Steel Castings

A technology for metal defects and welding structures, applied in welding equipment, metal processing equipment, workpiece edge parts, etc., can solve the problem of large amount of repair welding in the repair welding area, poor overall crack resistance, and difficulty in guaranteeing the stability and anti-fatigue performance of welding structures, etc. problem, to achieve the effect of inhibiting the harmful effect and improving the distribution of the thermal field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

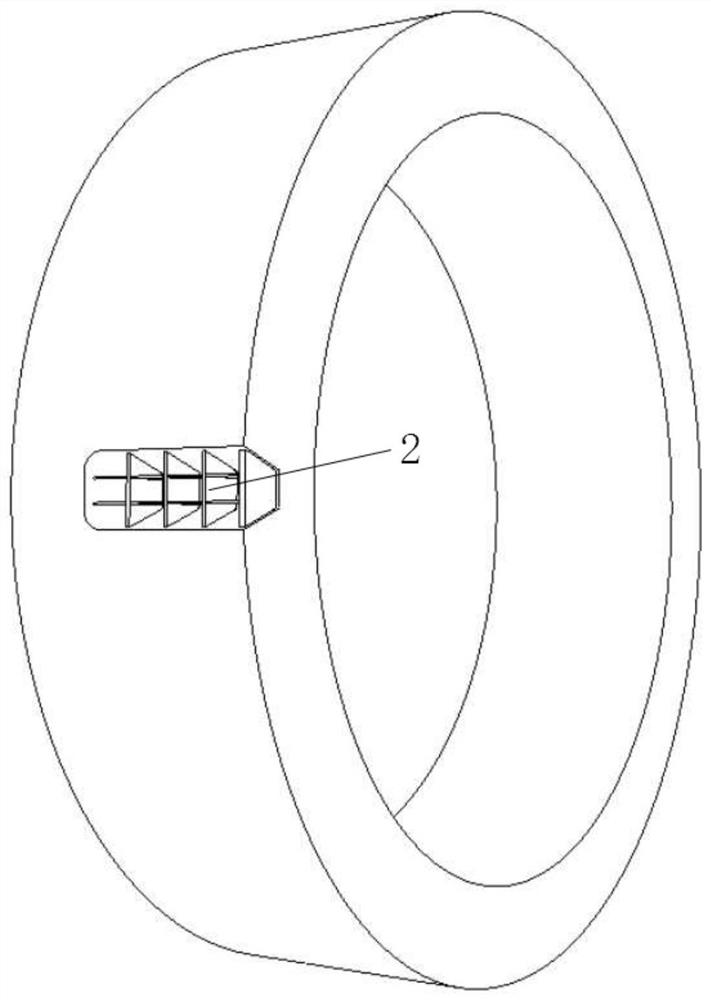

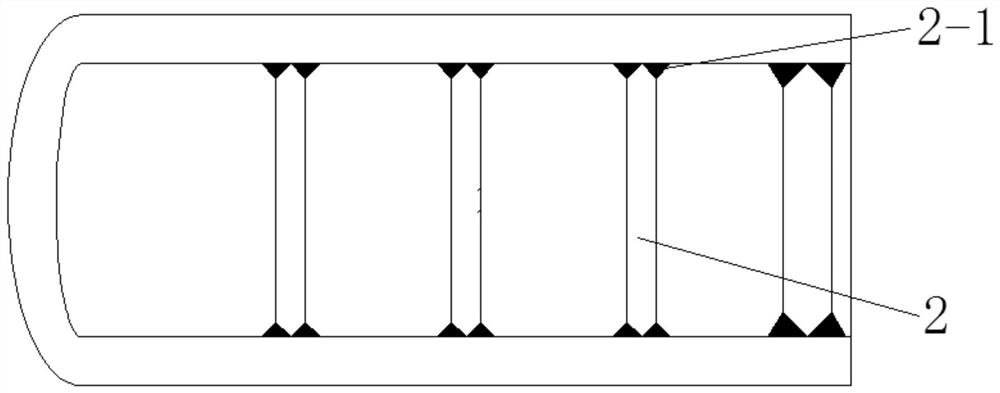

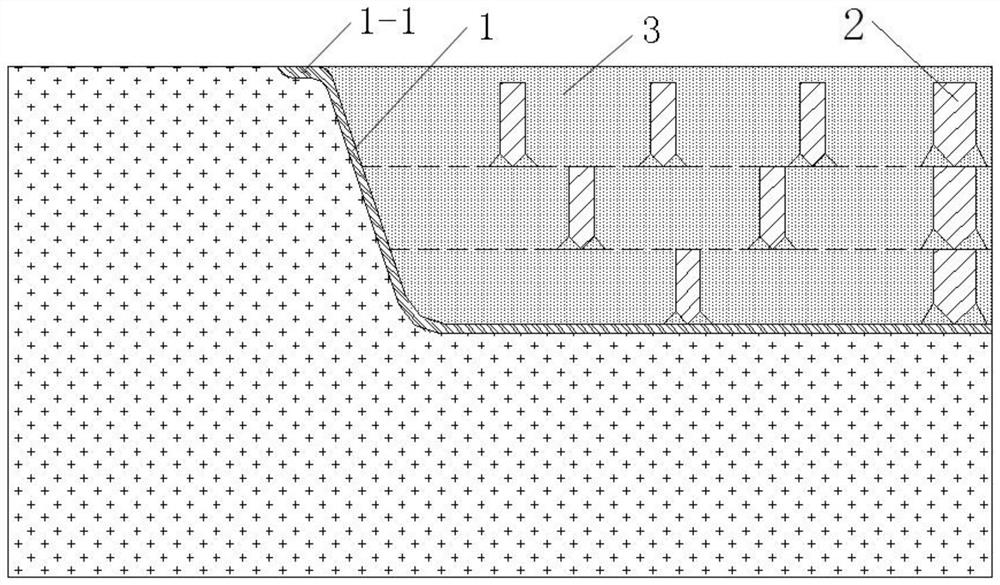

[0027] Specific Embodiment 1: The welding structure of the metal defect digging and repairing welding groove of the steel casting in this embodiment is to use welding deposited metal welding to form a layer of shell 1 on the welding groove wall and welding groove bottom of the digging and repairing welding. The inner wall of the body 1 is provided with a plurality of built-in steel webs 2 at intervals along the longitudinal and transverse directions of the weld, and the interior of the welding groove with a shell structure is separated into a plurality of partition spaces by the built-in steel webs 2 .

[0028] The specific plane geometric shape and contour size of each built-in steel web in this embodiment should be determined according to the geometric factors of the actual digging and repairing welding groove on site The hierarchical area inside the mouth and the groove cross-section where it is located are set identically to achieve gapless mosaic.

specific Embodiment approach 2

[0029] Specific implementation mode two: the reinforcement method of the welding structure of the metal defect digging and repairing welding groove of the steel casting in this embodiment is implemented according to the following steps:

[0030] Step 1. Welded shell structure: along the welded groove wall and the welded groove bottom, a shell 1 that is completely fused with the welded groove wall and the groove bottom is welded in advance with the deposited metal, and a shell with a shell is obtained. The welding groove of the body;

[0031] Step 2. Spatial arrangement of built-in steel webs: in the internal space enclosed by the shell structure in the welding groove, several rows and columns of built-in steel webs 2 are arranged at intervals along the longitudinal and transverse directions of the welds. , between the inner side of the shell 1 and the contact surfaces of the built-in steel webs 2 arranged vertically and horizontally, and between the built-in steel webs 2, so a...

specific Embodiment approach 3

[0034] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that in step 1, the metal defects inside the welding groove of the digging and repair welding are cleaned up in advance, and the welding groove wall and the welding groove bottom are inspected by coloring, and then polished Solder interface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com