Horizontal Dewar high-temperature superconducting current lead structure and design method

A high-temperature superconducting and current lead technology, applied in superconducting magnets/coils, circuits, electrical components, etc., to achieve the effects of easy installation and maintenance, superior heat dissipation, and favorable engineering promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

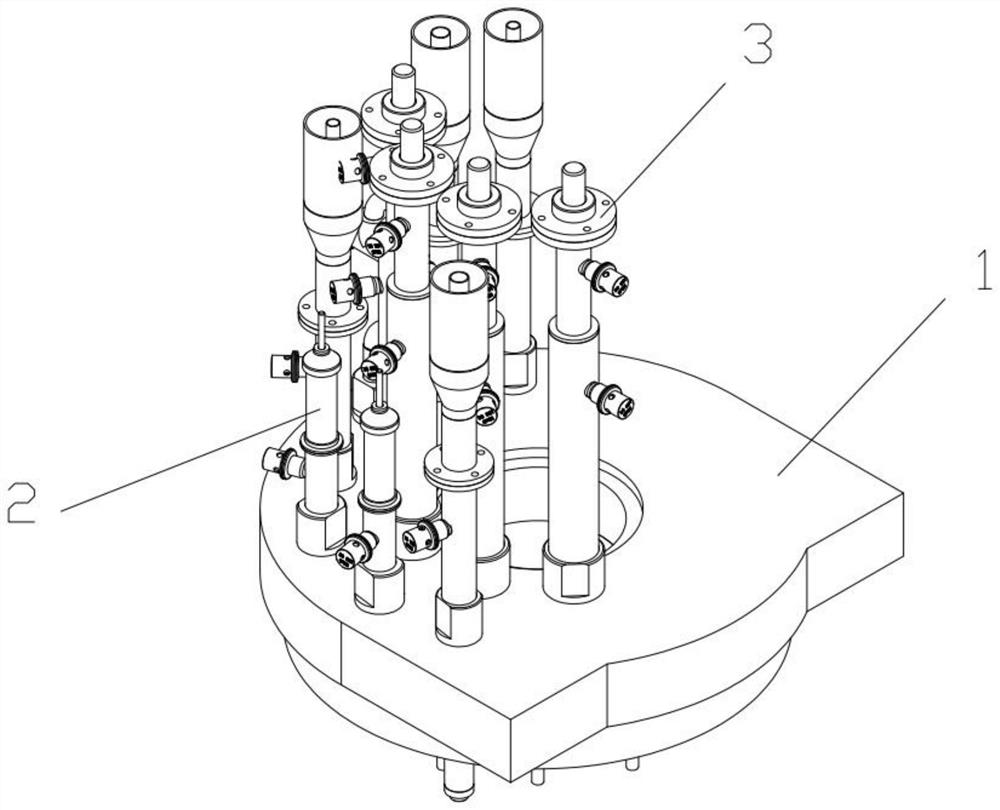

[0077] refer to Figure 1-11 , a horizontal Dewar high temperature superconducting current lead structure, used for coaxial horizontal transformers, the horizontal Dewar high temperature superconducting current lead structure includes:

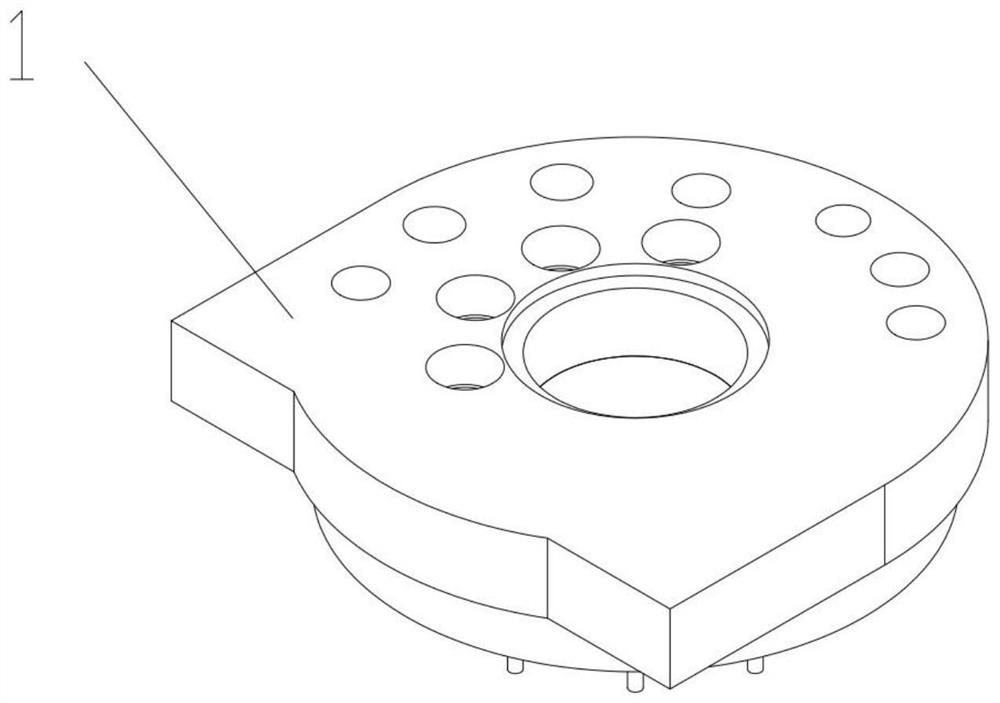

[0078] Dewar end cap 1 installed on the transformer;

[0079] A high-voltage lead wire segment 2 and a low-voltage lead wire segment 3 are installed on the Dewar end cover 1;

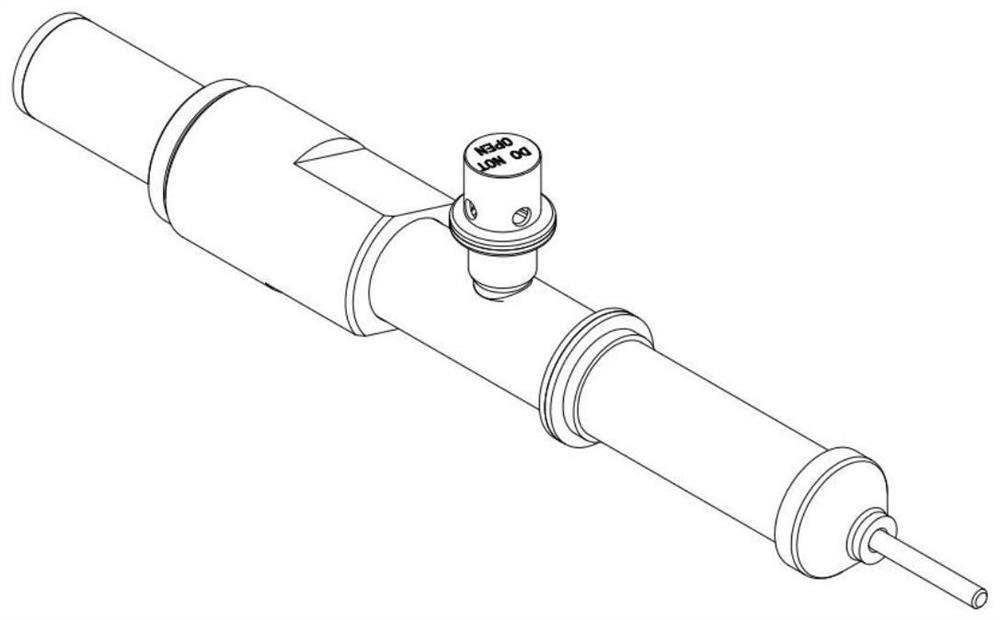

[0080] The first end of the high-voltage lead section 2 is connected to the transformer through the first high-voltage and low-voltage lead 4, and the second end of the high-voltage lead section 2 is connected to the first high-temperature superconducting lead section 5, which is placed in liquid nitrogen in liquid nitrogen in the cooler;

[0081] The first end of the low-voltage lead section 3 is connected to the transformer through the second high-voltage and low-voltage lead wire, the second end of the low-voltage lead section 3 is connected to the second high-temp...

Embodiment 2

[0089] This embodiment is a design method for the horizontal Dewar high temperature superconducting current lead structure provided in Embodiment 1, including the following steps:

[0090] S10, determining the length of the Dewar high voltage lead wire and the Dewar low voltage lead wire;

[0091] S20. Measure the outer diameter of the Dewar high-voltage lead wire and the Dewar low-voltage lead wire, and then determine the inner diameter of the Dewar high-voltage lead wire and the Dewar low-voltage lead wire according to the known rated current; meanwhile, optimize the radius of the Dewar high-voltage lead wire and the Dewar low-voltage lead wire and length to get the optimal aspect ratio to achieve minimum heat leakage.

[0092] In the present embodiment, in step S20, the radius and length of the Dewar high-voltage lead wire and the Dewar low-voltage lead wire are optimized to obtain the optimal aspect ratio. The specific steps are as follows:

[0093] S21. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com