High crystal quality polysilicon ingot thermal field

A technology of crystal quality and polycrystalline silicon, applied in the direction of crystal growth, polycrystalline material growth, single crystal growth, etc., can solve the problem of no regionalized heat flow control, and achieve the effect of shortening melting time, reducing energy consumption, and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

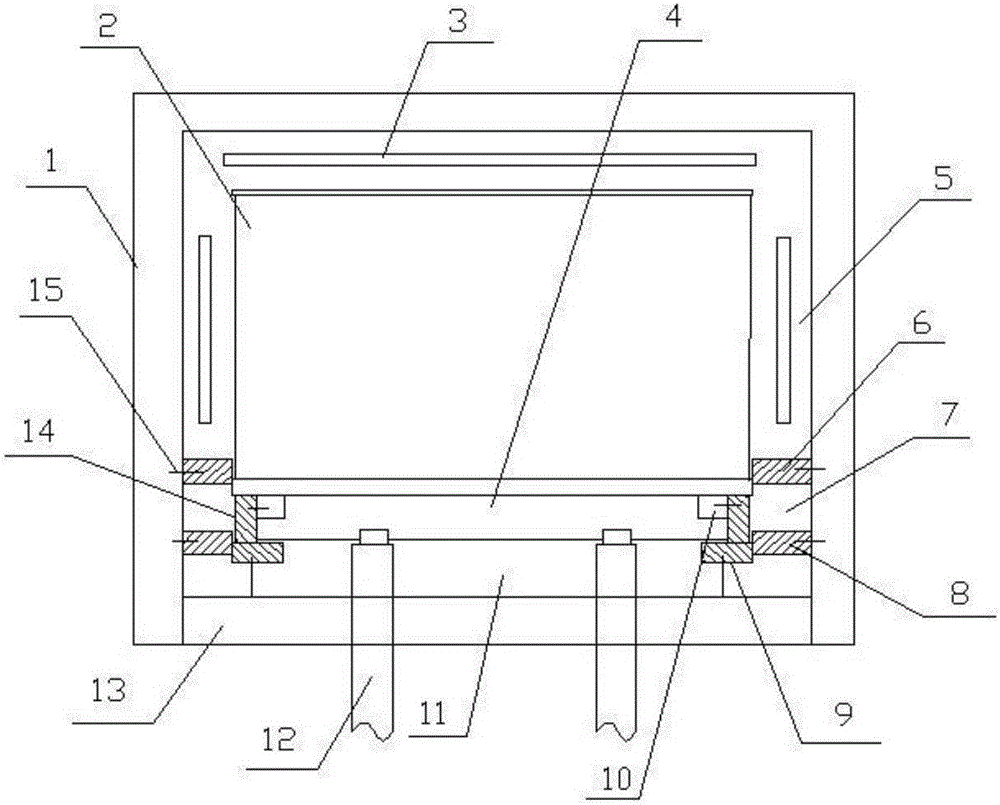

[0014] Embodiment 1, with reference to figure 1 , a high crystal quality polysilicon ingot thermal field, comprising an incubator 1 and a crucible 2 arranged in the furnace body, the crucible 2 is arranged in the incubator 1, the bottom of the incubator 1 is provided with an opening, and the bottom opening of the incubator is provided with There is a movable bottom plate 13, a heating device 3 is arranged in the incubator 1, a support mechanism for the crucible 2 is arranged on the movable bottom plate 13 of the incubator 1, and a thermal field is arranged in the incubator 1 above, below and around the crucible 2, so The heat field is divided into an upper heat field area 5, a middle heat field area 7, and a lower heat field area 11 through a multi-layer heat insulation mechanism, and the support mechanism includes a directional condensation plate 4 for placing the crucible 2 and a supporting directional condensation plate 4 The vertical struts 12 are installed in the furnace ...

Embodiment 2

[0016] Embodiment 2, the high crystal quality polysilicon ingot heat field described in embodiment 1 is provided with a circle of heat insulation wrapping around the outer periphery of the directional condensation plate 4; The movable insulating partition 14 opposite to the plate 8 is overlapped on the directional condensing plate 4 through the graphite block 10; a step matched with the graphite block 10 is provided on the top edge of the directional condensing plate 4.

Embodiment 3

[0017] Embodiment 3, the high crystal quality polysilicon ingot thermal field described in embodiment 1-2, is provided with a circle of motion insulation partitions 9 at the bottom of the directional condensation block 4, and the motion insulation partitions 9 are installed by carbon-carbon components 15 On the movable bottom plate, there is a heat transfer gap between the moving insulation partition 9 and the directional condensation block 4, and the gap rate is 50%-80%. The ratio of the gap between the plates to the total gap between the bottom of the crucible and the movable floor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com