A thermal insulation structure with adjustable axial temperature gradient applied to the growth of sapphire single crystal by foaming method

A technology of temperature gradient and sapphire, which is applied in the direction of single crystal growth, single crystal growth, and seed crystal remaining in the molten liquid during growth, which can solve the problems of difficult handling and disassembly, only a small amount of use, and pollution of the growth environment. Effects of improving crystal quality, reducing thermal stress, and smooth temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

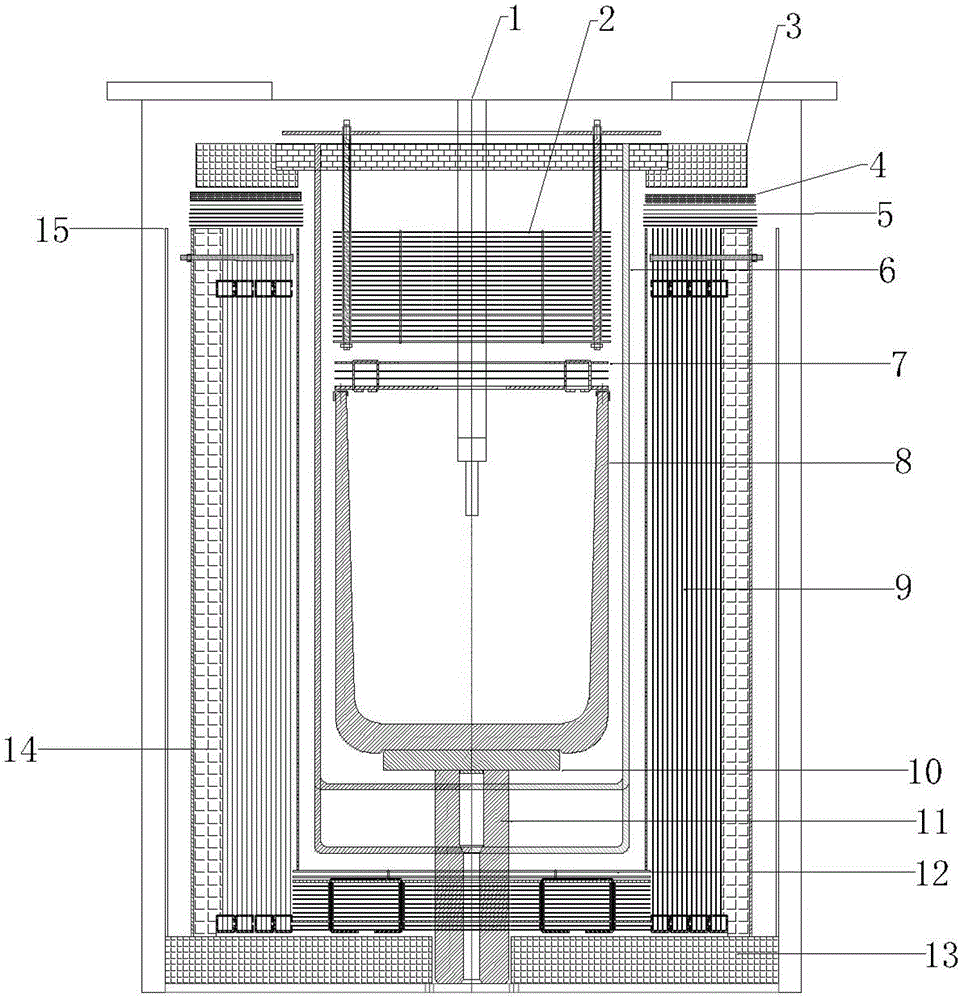

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0027] The thermal insulation structure applied to the Kyropoulos sapphire single crystal growth of the present invention firstly uses several groups of thin metal plate heat shields that are placed horizontally, vertically and obliquely (the thin metal plates are made of molybdenum and tungsten metals with a thickness of 1 mm and 2 mm respectively). The distance between each layer is about 3-5mm, and the narrow molybdenum strips are used as vertical interval support in the middle to prevent excessive deformation of the heat shield at high temperature;), and the inner zirconia hollow bulb shell realizes the thermal field Thermal insulation performance to ensure that the melting point of alumina can be achieved to achieve crystal growth and protect the furnace cavity from high temperature damage; then the thin plate heat shield is connected into a cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com