Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and preparation method thereof

An aluminum alloy profile, stress corrosion technology, applied in the field of metal materials and their processing, can solve problems such as affecting the safety of train operation, harsh service environment, stress corrosion cracking, etc., to improve corrosion resistance, improve surface quality, and reduce cracks tendentious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

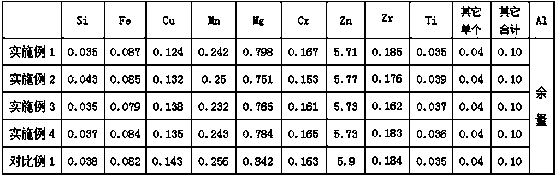

[0042]In Example 1 of the present invention, the mass percentage of each element of the chemical composition of the aluminum alloy is shown in Table 1, and the manufacturing method includes the following: (1) adding industrial-grade aluminum ingots with a purity of 99.70% or more and various required alloying elements for melting, melting The temperature is 740°C~760°C; the raw materials are fully melted to obtain a melt with uniform and stable composition. (2) The temperature of the molten aluminum is kept at 730~760°C, the melt is refined, the slag inclusions are removed, and the alloy composition content is adjusted. (3) Degassing and filtering the melt, the hydrogen content of the melt after degassing is 0.086ml / 100gAl. (4) Cast the melt after degassing and slag removal, and control the temperature of the molten aluminum on the casting platform at 690~710°C. (5) Carry out homogenization annealing treatment on the ingot, homogenization annealing process: 360°C±5°C / 3.5h+420...

Embodiment 2

[0045] In Example 2 of the present invention, the mass percentage of each element of the chemical composition of the aluminum alloy is shown in Table 1, and the manufacturing method includes the following: (1) adding industrial-grade aluminum ingots with a purity of 99.70% or more and various required alloy elements for melting, melting The temperature is 740~760°C to fully melt the raw materials and obtain a melt with uniform and stable composition. (2) The temperature of the molten aluminum is kept at 730~760°C, the melt is refined, the slag inclusions are removed, and the alloy composition content is adjusted. (3) Degassing and filtering the melt, the hydrogen content of the melt after degassing is 0.082ml / 100gAl. (4) Cast the melt after degassing and slag removal, and control the temperature of the molten aluminum on the casting platform at 690~710°C. (5) Perform homogenization annealing treatment on the ingot, homogenization annealing process: 360°C±5°C / 4h+420°C±5°C / 7h+4...

Embodiment 3

[0048] In Example 3 of the present invention, the mass percentage of each element of the chemical composition of the aluminum alloy is shown in Table 1, and the manufacturing method includes the following: (1) adding industrial-grade aluminum ingots with a purity of 99.70% or more and various required alloy elements for melting, melting The temperature is 740~760°C to fully melt the raw materials and obtain a melt with uniform and stable composition. (2) The temperature of the molten aluminum is kept at 730~760°C, the melt is refined, the slag inclusions are removed, and the alloy composition content is adjusted. (3) The melt is degassed and filtered, and the hydrogen content of the melt after degassing is 0.085ml / 100gAl. (4) Cast the melt after degassing and slag removal, and control the temperature of the molten aluminum on the casting platform at 690~710°C; (5) Perform homogenization annealing treatment on the ingot, homogenization annealing process: 360°C±5°C / 4h+420℃±5℃ / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com