Catalyst conversion method for producing high-octane gasoline by using crude oil

A high-octane gasoline, catalytic conversion method technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of underutilization of gasoline latent content, poor gasoline properties, affecting gasoline octane number, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

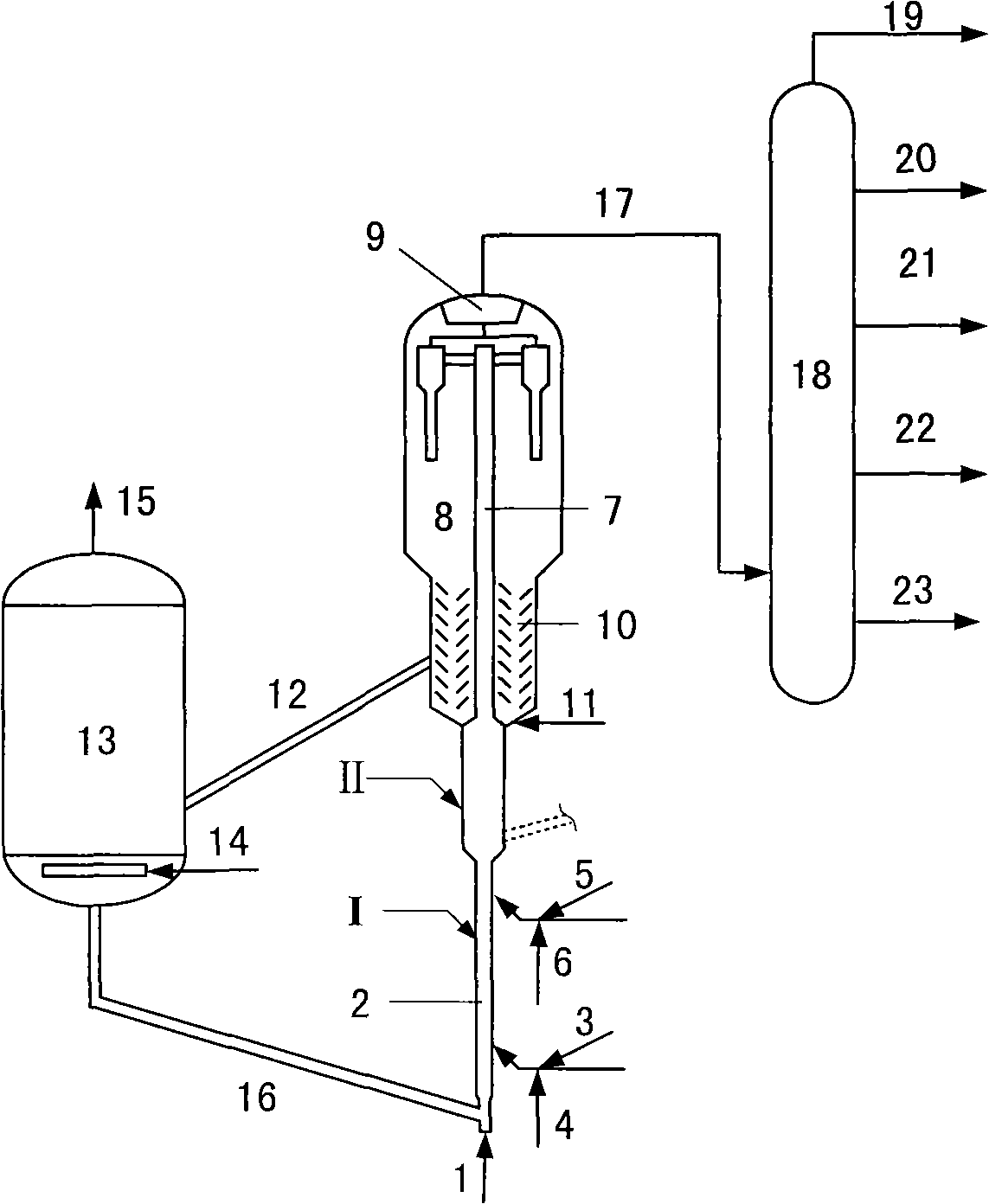

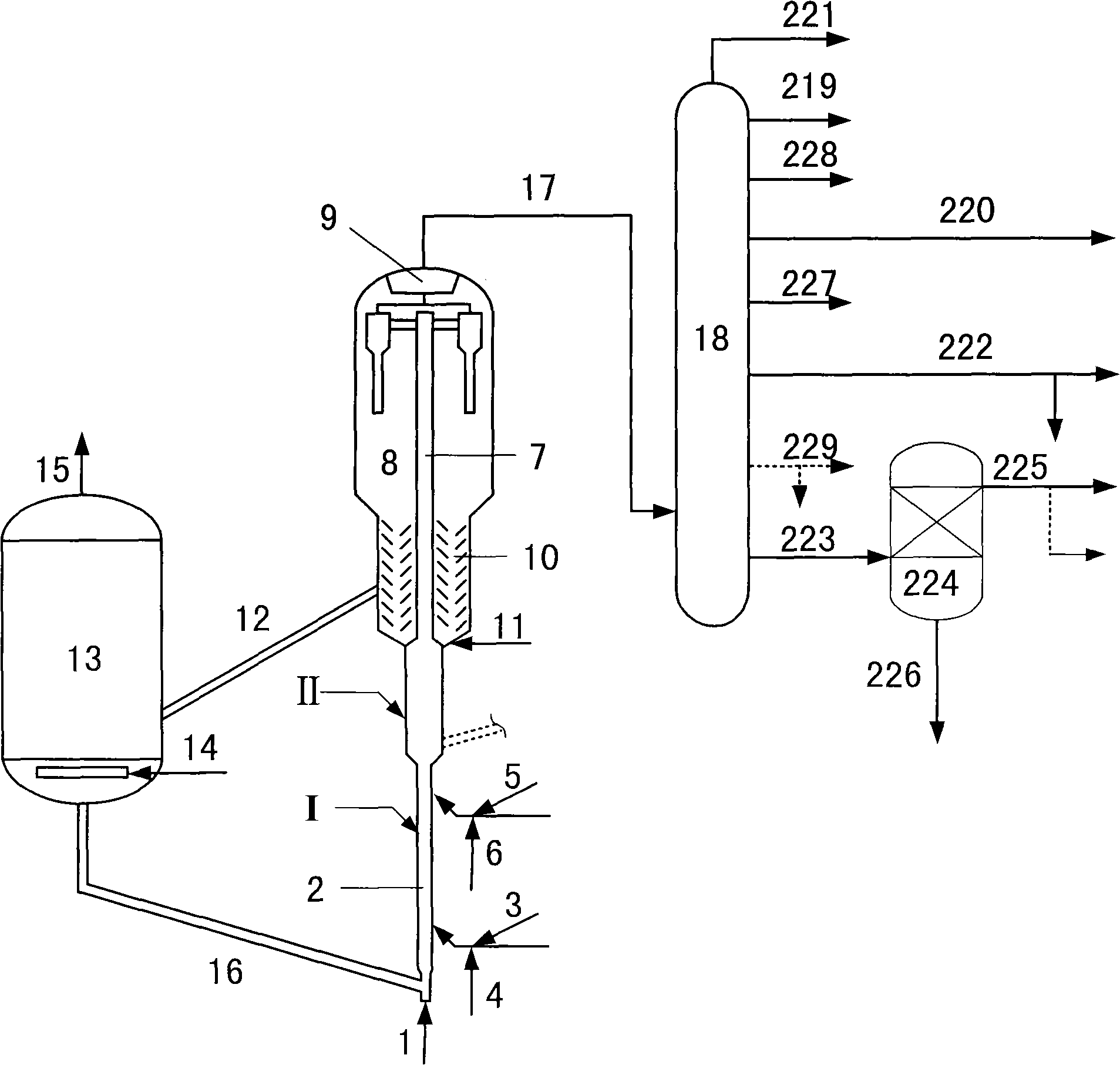

[0084] This embodiment follows the attached image 3 MGCO-2 was used as the catalyst, and the feedstock oil A was directly used as the easily cracked feedstock oil for catalytic cracking. The test was carried out on the medium-sized device from the riser reactor. The easily cracked feedstock oil entered the middle and upper part of the reaction zone I. The cracked feedstock oil enters the bottom of the reaction zone I. At the bottom of reaction zone I, the refractory feedstock oil is at a reaction temperature of 600℃ and a weight hourly space velocity of 240h -1 , The weight ratio of catalytic cracking catalyst to difficult-to-crack feedstock oil is 30, and the weight ratio of steam to difficult-to-crack feedstock oil is 0.20. Time and space speed 90h -1 , The weight ratio of the catalytic cracking catalyst to the easily cracked feed oil is 10, and the weight ratio of steam to the easily cracked feed oil is 0.15 for the cracking reaction. In the reaction zone II, the reactant f...

Embodiment 2

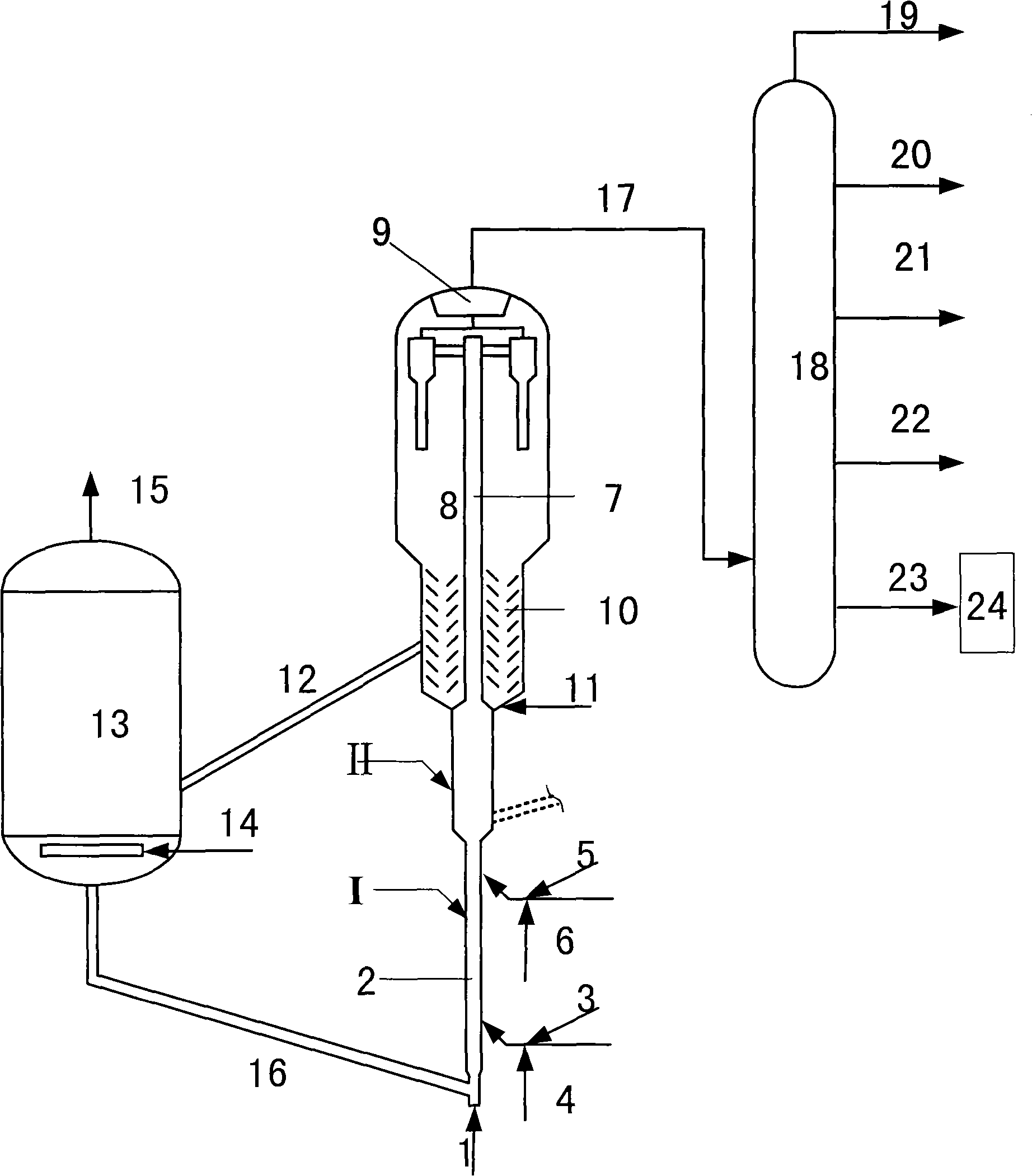

[0090] This embodiment follows the attached Figure 4 MGCO-2 was used as the catalyst, and the feed oil B was directly used as the refractory feed oil for catalytic cracking. The test was carried out on a medium-sized device from the riser reactor. The refractory feed oil enters the bottom of the reaction zone I to react. The cracked feedstock oil enters the middle and upper part of reaction zone I for reaction. At the bottom of the reaction zone I, the refractory feedstock oil has a reaction temperature of 580℃ and a weight hourly space velocity of 200h -1 , The weight ratio of the catalytic cracking catalyst to the refractory feed oil is 60, and the weight ratio of steam to the refractory feed oil is 0.20. The cracking reaction is carried out; in the upper middle and upper part of the reaction zone I, the easily cracked feed oil is at a reaction temperature of 550℃ and heavy Time and space speed 120h -1 , The weight ratio of catalytic cracking catalyst to easily cracked feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com