High-toughness and high-red-hardness high-speed tool steel

A high-speed tool steel and red-hardness technology, applied in the field of tool steel, can solve the problem of high cost of high-speed steel and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The high-speed tool steel composition table 1 of the embodiment of the present invention (the remainder is Fe and trace impurity elements not specifically indicated), the manufacturing process is: intermediate frequency + external refining + electroslag remelting → electroslag ingot → fast forging, precision forging → Billet or bar stock→rolling mill finished product→annealing→finishing→production of various specifications of forged and rolled materials.

[0014] Table 1 Composition table of high-speed tool steel

[0015] .

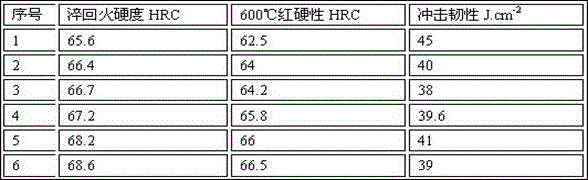

[0016] After taking a sample of the above-mentioned examples for heat treatment (quenching + tempering), the hardness and impact toughness at room temperature are tested,

[0017] And the hardness at 600℃, the results are shown in Table 2.

[0018] Table 2 High-speed tool steel properties

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com