Aluminum Tube Continuous Extrusion Die

A technology for extrusion die and aluminum tube, which is applied in the field of continuous extrusion die for aluminum tubes, can solve the problems of weak adhesion between the wear-resistant layer and the substrate, weak adhesion between the wear-resistant layer and the substrate, and short service life of the mold. Achieve the effect of small grain size, good dimensional stability and good red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides an aluminum tube extrusion molding die, which specifically includes a male die, a female die and a forming mandrel 3 arranged on the male die.

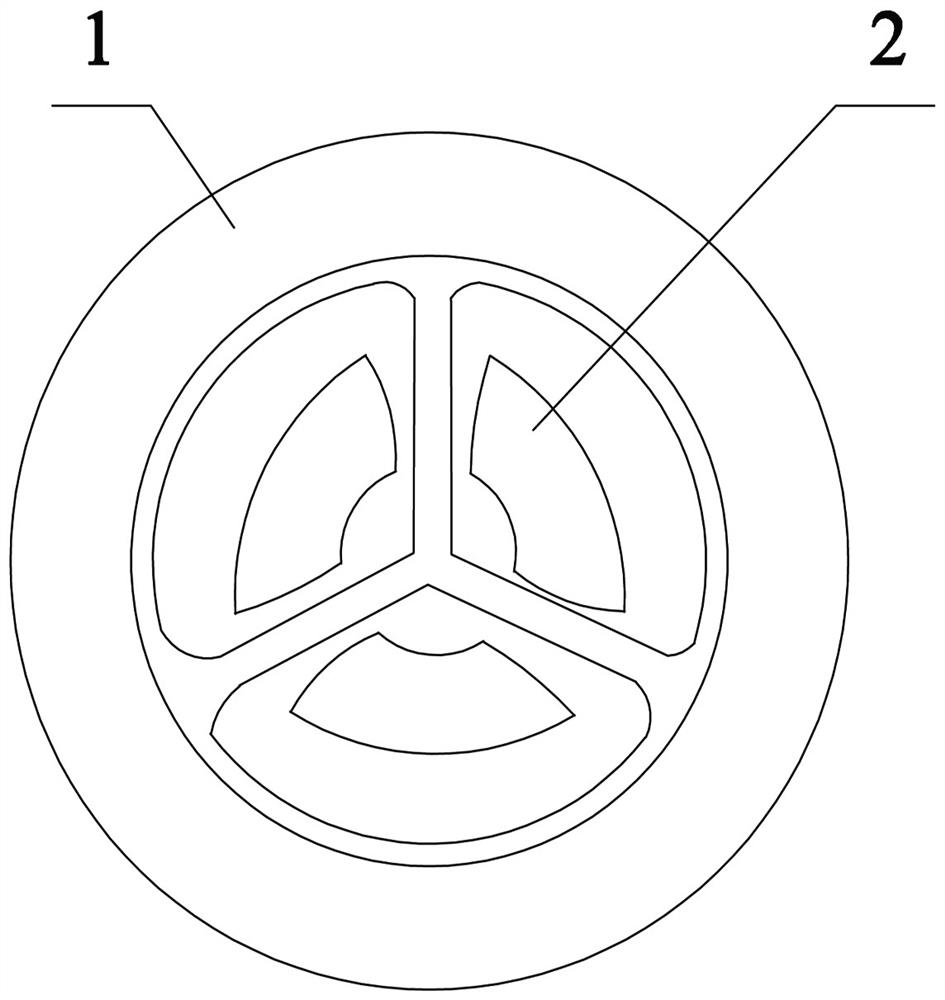

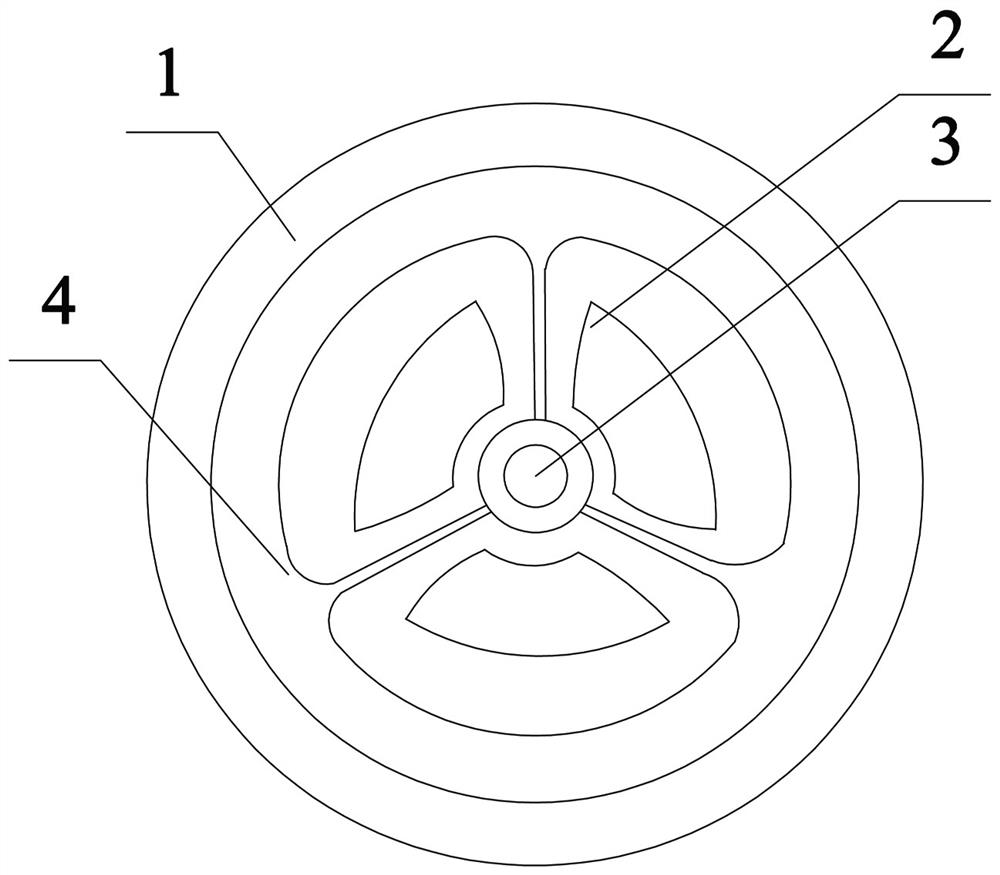

[0045] Such as figure 1 with figure 2 As shown, the punch includes a cylindrical punch base 1 , a punch forming boss 4 and three distribution grooves 2 passing through the punch forming boss 4 and the punch base 1 . Wherein the cylindrical punch base 1 and the punch forming boss 4 are integrated, and the center of the outer end surface of the punch forming boss 4 is provided with an assembly blind hole.

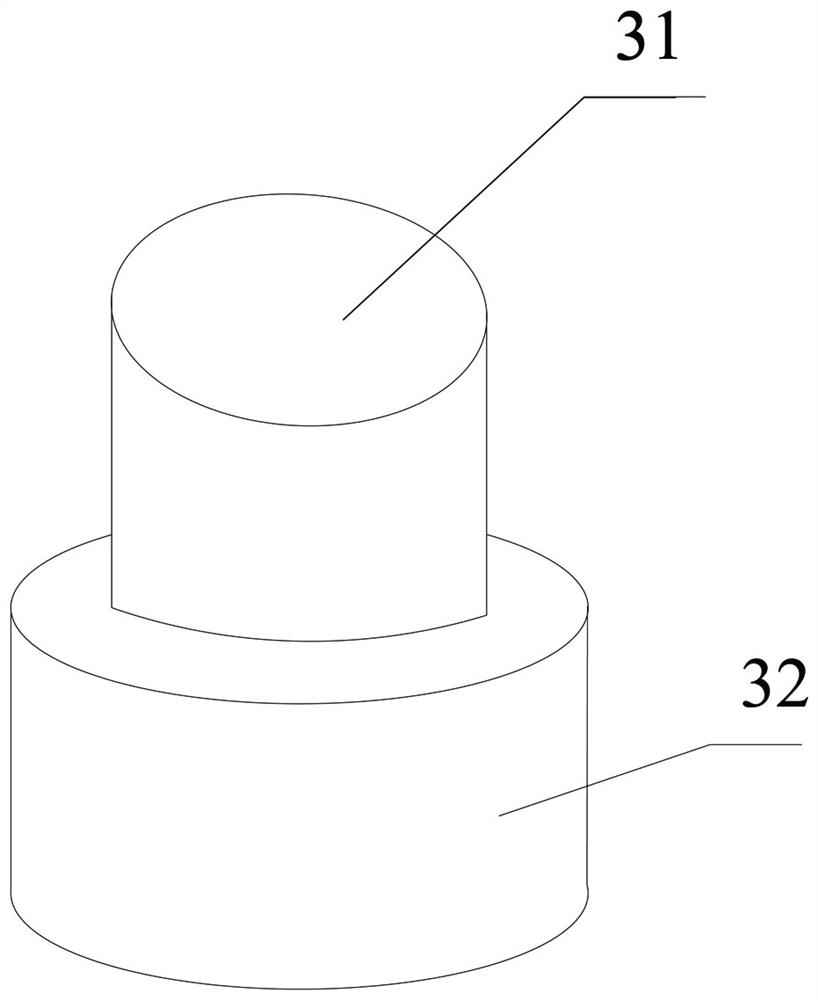

[0046] Such as image 3 with Figure 4 As shown, the forming mandrel 3 includes a forming mandrel base 34 and a wear-resistant and corrosion-resistant coating 35 deposited on the surface of the forming mandrel base 34 . Wherein, the wear-resistant and corrosion-resistant coating 35 is a nano-titanium nitride coating, and the thickness of the nano-titanium nitride coating is 5 microns. The forming...

Embodiment 2

[0062] This embodiment provides a continuous extrusion die for aluminum tubes. The specific structure differs from that in Embodiment 1 in that:

[0063] The thickness of the wear-resistant and corrosion-resistant coating is 10 microns, and the thickness of the formed gasket 8 is 3 millimeters; the wear-resistant and corrosion-resistant coating is a nano-titanium carbide layer; the forming mandrel substrate and the forming The base of the gasket is processed from cemented carbide materials including the following mass percentage components: WC 85%, TiC 5%, Co 10%.

Embodiment 3

[0065] This embodiment provides a continuous extrusion die for aluminum tubes, the specific structure of which is roughly the same as that in Embodiment 1, except that:

[0066] The thickness of the wear-resistant and corrosion-resistant coating is 8 microns, the thickness of the formed gasket is 8 mm, and the wear-resistant and corrosion-resistant coating is a nano-titanium carbonitride layer; the forming mandrel base and the The formed gasket base is processed from cemented carbide materials including the following mass percentage components: WC 82%, TiC 6%, Co 8%, TaC 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com