Electrochemical corrosion preparation method for microporous battery aluminum foil

A chemical corrosion and electrochemical technology, applied in battery electrodes, electrode manufacturing, electrode carriers/current collectors, etc., can solve the problems of reducing the contact resistance of alumina foil and reducing the mechanical strength of aluminum foil, achieving good performance consistency and controlling product quality. And the effect of production speed and environmental pollution is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

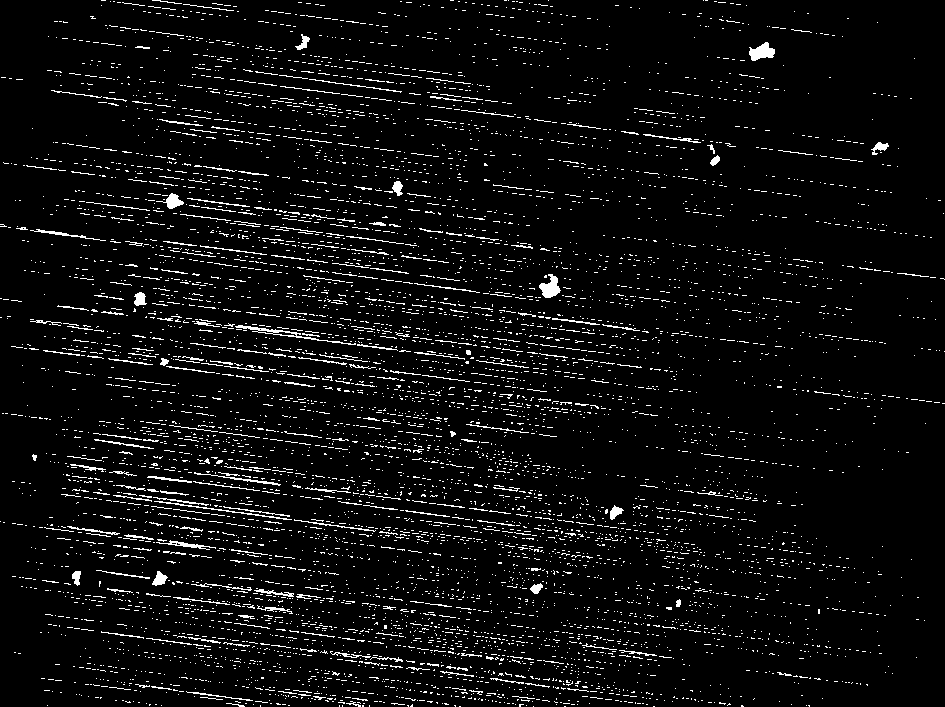

[0027] Such as Figure 1-2 Shown, a microporous battery aluminum foil, a microscopic image of the microporous battery aluminum foil. The microporous battery aluminum foil has 1000-1500 through holes with a diameter of 10-15 μm and 1000-3000 blind holes with a diameter of 10-50 μm per square centimeter. The holes and blind holes are irregular in shape, and the junction between each hole and the surface of the aluminum foil is an irregular arc transition, and the diameters in different directions are different; the upper and lower surfaces of the aluminum foil are distributed with multiple notches of different lengths and depths. The depth of the marks is 1-3 μm, the width is 1-5 μm, and the length is 100-1000 μm. The thickness of the battery aluminum foil is 15 μm, and 10 μm, 12 μm, 16 μm, 20 μm, etc. can also be selected.

[0028] The above-mentioned microporous metal material, that is, microporous battery aluminum foil, is made by chemical liquid corrosion method, and is car...

Embodiment 2

[0050] A microporous metal material, the material is battery aluminum foil, the microporous battery aluminum foil has 1000-1500 through holes with a diameter of 10-15μm and 1000-3000 through-holes with a diameter of 10-50μm per square centimeter. Uniform blind holes, each through hole and blind hole is irregular in shape, and the junction of each hole and the surface of the aluminum foil is an irregular arc transition, and the diameters in different directions are different; the upper and lower surfaces of the aluminum foil are distributed with multiple lengths Scores of different depths, 1-3 μm deep, 1-5 μm wide, and 100-1000 μm long, the thickness of the battery aluminum foil is 15 μm, and 10 μm, 12 μm, 16 μm, 20 μm, etc. can also be selected.

[0051] Microporous battery aluminum foil is made by chemical liquid corrosion method, follow the steps below:

[0052] 1) Clean the surface of the rolled battery aluminum foil to remove the lubricant: the composition of the first cle...

Embodiment 3

[0060] The preparation method of microporous battery aluminum foil electrochemical corrosion is carried out according to the following steps:

[0061] 1) Clean the surface of the rolled battery aluminum foil to remove the lubricant: the composition of the first cleaning solution is 20g / L NaOH, 40g / L NaOH 2 CO 3 , 10g / L of Na 3 PO 4 , pass the rolled aluminum foil through the first cleaning solution, and keep it in the first cleaning solution for 10s.

[0062] 2) Press the cleaned aluminum foil into the chemical etching solution: the composition of the chemical etching solution is: 1.5mol / L NaCl, 0.3mol / L BaCl 2 , 0.2mol / L CaCl 2 , 0.5mol / L CuCl 2 , 0.3mol / L FeCl 3 , the corrosion tank is used as the cathode, the battery aluminum foil is used as the anode, and 24V DC is applied for corrosion. The DC can be set to a safe voltage such as 36V, 48V, and the residence time of the aluminum foil in the corrosive agent is 60s. At this stage, ensure that the upper and lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com