Preparation method of sushi soybean sauce

A soy sauce and sushi technology, which is applied in the field of food processing, can solve the problems of unseen sushi soy sauce preparation method and few types of seasoning soy sauce, and achieve the effects of reasonable proportion, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

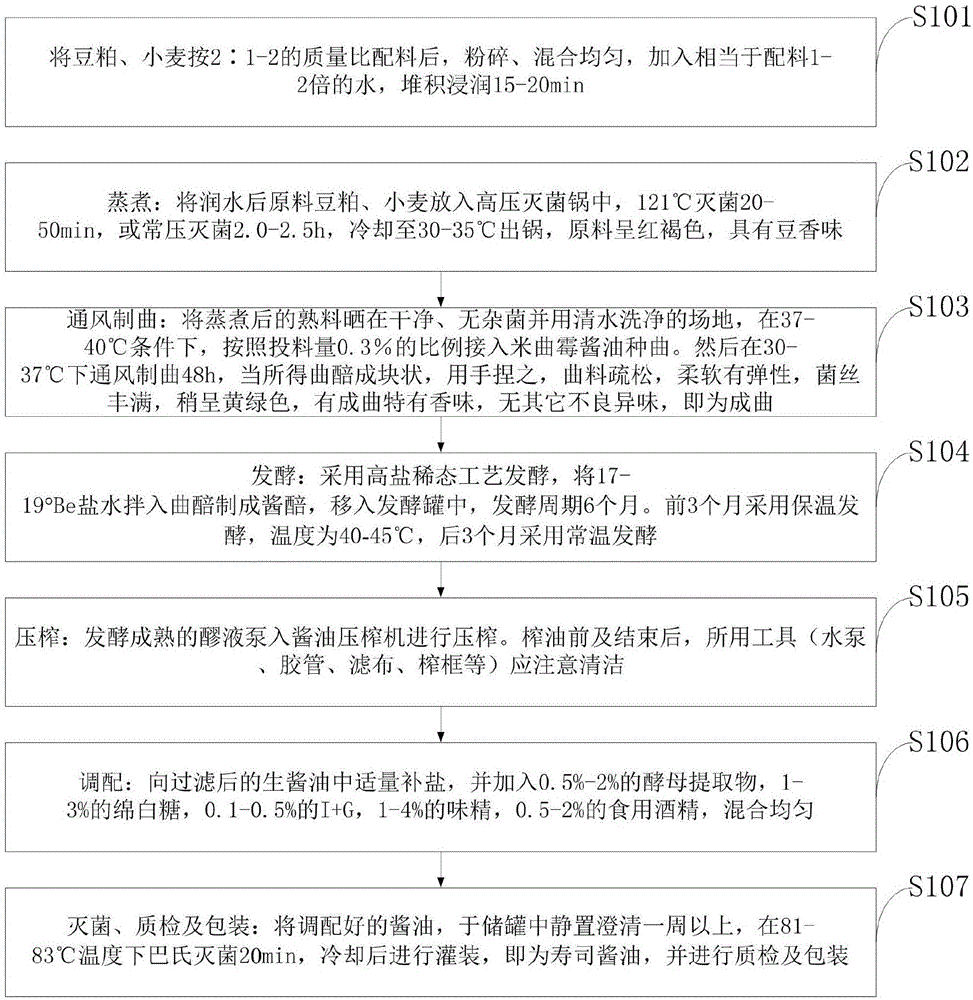

[0023] The preparation method of the sushi soy sauce that the embodiment of the present invention provides, comprises the following steps:

[0024] S101: After batching soybean meal and wheat in a mass ratio of 2:1-2, crush and mix evenly, add 1-2 times the amount of water equivalent to the batching, and accumulate and infiltrate for 15-20 minutes.

[0025] S102: Cooking: put the moistened soybean meal and wheat into an autoclave, sterilize at 121°C for 20-50min, or sterilize at normal pressure for 2.0-2.5h, cool to 30-35°C and take out the pot, the raw material turns red Brown in color with bean aroma.

[0026] S103: Ventilated koji making: Dry the cooked clinker in a clean place free of bacteria and washed with water, and add Aspergillus oryzae soy sauce seed koji at a ratio of 0.3% of the feeding amount under the condition of 37-40°C. Then ventilate and make koji at 30-37°C for 48 hours. When the obtained koji grains form a block, pinch it by hand, the koji material is loo...

Embodiment 1

[0033] 1) After batching soybean meal and wheat according to the mass ratio of 2:1.2, crush and mix evenly, add water equivalent to 1.5 times of the batching, and accumulate and infiltrate for 18 minutes;

[0034] 2) Cooking: Put the moistened soybean meal and wheat into an autoclave, sterilize at 121°C for 30 minutes, cool to 35°C, and take out the pot. The raw materials are reddish brown and have a bean flavor.

[0035] 3) Ventilated koji making: put the clinker after cooking in a clean place free of bacteria and washed with clear water. Under the condition of 37-40°C, add Aspergillus oryzae soy sauce seed koji according to the ratio of 0.3% of the feeding amount. Then ventilate and make koji at 35-37°C for 48 hours. When the obtained koji grains form a block, pinch it by hand. The koji material is loose, soft and elastic, and the hyphae are plump and slightly yellow-green. Unpleasant smell, that is into the koji.

[0036] 4) Fermentation: Fermentation using high-salt dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com