Novel production process for cut tobacco stems

A preparation process and technology of tobacco stems, which are applied in the field of preparation of tobacco stems and cut stems, can solve the problems of increasing the weight, density and suction resistance of cigarettes, the cut stems are easy to be cut into shreds, and affecting the rolling quality, etc. The effect of reducing impurities, good adaptability and good curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

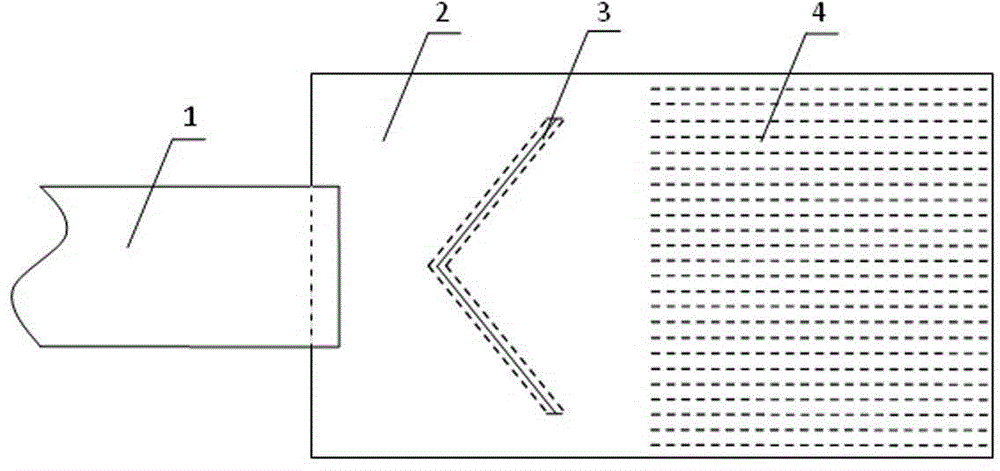

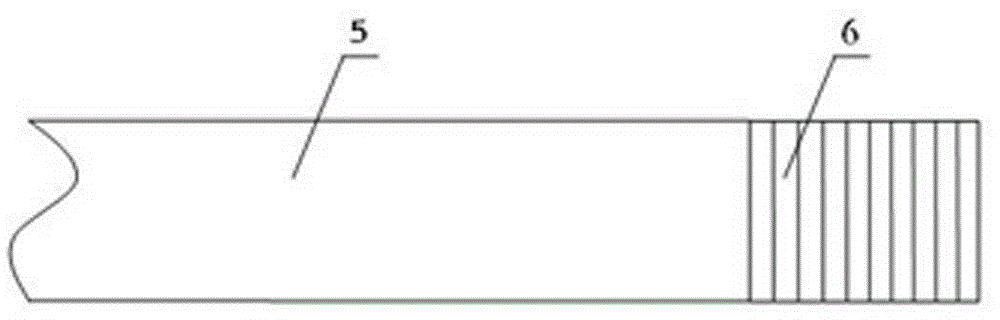

Image

Examples

Embodiment Construction

[0024] The novel preparation process steps of shredded tobacco stems of the present invention are as follows:

[0025] (1) Vacuum moisture resurgence and steaming stems: put the tobacco stems in a vacuum moisture resurgence device, vacuumize to a vacuum degree of -0.03~-0.06MPa, spray atomized water and steam at the same time after vacuuming, and replenish water by 10.0-16.0%. The steam pressure is 0.2-0.4MPa. After the water replenishment is completed, continue to feed steam to the pressure of 0.1-0.3MPa. After 10-30 seconds of constant pressure, the material is discharged. The moisture content of the tobacco stem is 30.0±2.0%;

[0026] (2) Stem storage: transport the steamed stems to the storage cabinet for storage, the storage time is 2-4 hours, to improve the moisture uniformity of the tobacco stems and make them fully penetrate;

[0027] (3) Warming and humidification: the tobacco stems after storage are transported to the HT warming and humidifying equipment through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com