Complex enzyme preparation for tobacco stalk treatment and tobacco stalk treatment method

A compound enzyme preparation and treatment method technology, which is applied in the field of tobacco stem treatment compound enzyme preparation and tobacco stem treatment, and can solve the problems of complicated process and reducing the content of aroma substances in tobacco stems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The weight percentages of the components of the compound enzyme preparation are: 3% of neutral protease, 3% of cellulase, 4% of pectinase, 8% of laccase, 1% of nicotine dehydrogenase and 81% of water.

[0083] Mix the compound enzyme preparation with water at a ratio of 1:9 to obtain a mixed solution, spray 5 kg of the mixed solution evenly before washing the stems per 100 kg of tobacco stems, place it at a temperature of 25°C and a humidity of 80% for 1 hour, and treat the rest according to the conventional process conduct.

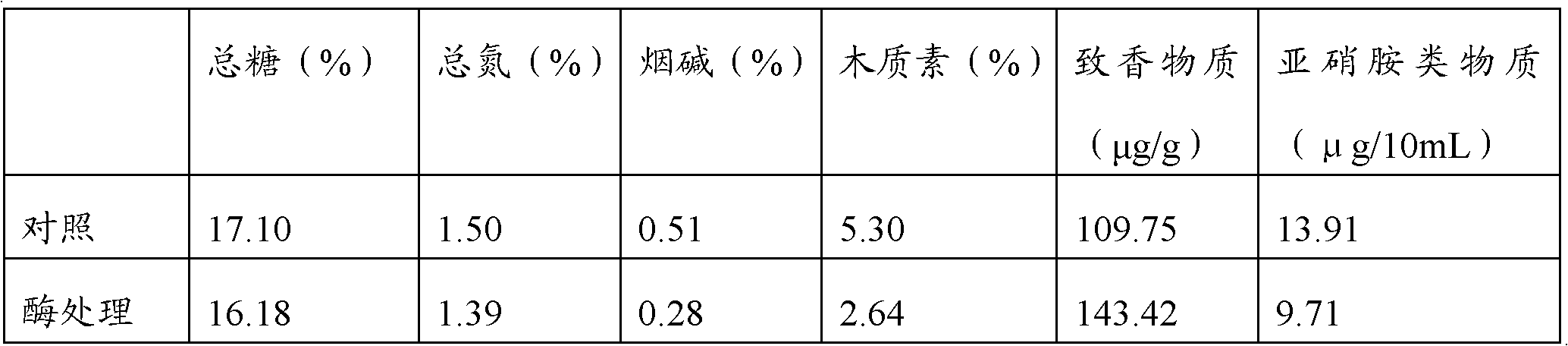

[0084] According to the national standard GB / T5606.1 for cigarettes, the cut stems obtained by the treatment in this example were compared with the cut stems obtained by the normal process, and the results were as follows:

[0085] Table 1

[0086] project

luster

aroma

Harmonize

Miscellaneous

irritant

total

normal process

4

28

5

9

16

22

84

Enz...

Embodiment 2

[0093] The weight percentages of the components of the compound enzyme preparation are: 1% of neutral protease, 1% of cellulase, 1% of pectinase, 3% of laccase, 1% of nicotine dehydrogenase and 93% of water.

[0094] Mix the compound enzyme preparation with water at a ratio of 1:9 to obtain a mixed solution, spray 5 kg of the mixed solution evenly before washing the stems per 100 kg of tobacco stems, place it at a temperature of 25°C and a humidity of 80% for 1 hour, and treat the rest according to the conventional process conduct.

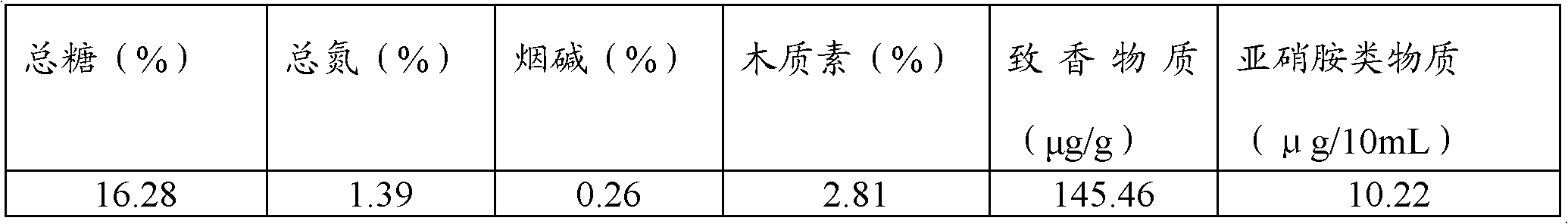

[0095] The shredded stems prepared according to this embodiment have full aroma, less miscellaneous gas, low irritation, soft and harmonious smoke. Some of its chemical components are as follows:

[0096]

Embodiment 3

[0098] The weight percentages of the components of the compound enzyme preparation are: 4% of neutral protease, 4% of cellulase, 4% of pectinase, 8% of laccase, 2% of nicotine dehydrogenase and 78% of water.

[0099] Mix the compound enzyme preparation with water at a ratio of 1:9 to obtain a mixed solution, and spray 5 kg of the mixed solution evenly before washing the stems per 100 kg of tobacco stems, place it for 1 hour at a temperature of 45 ° C and a humidity of 50%, and the rest shall be treated according to the conventional process conduct.

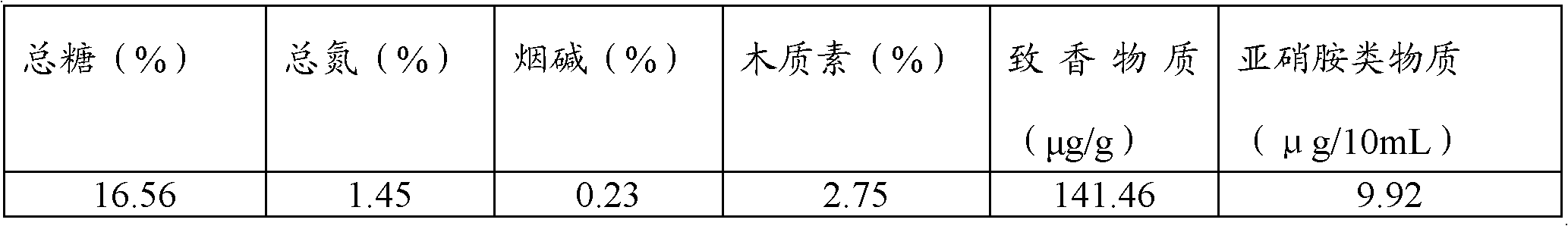

[0100] The shredded stems prepared according to this embodiment have full aroma, less miscellaneous gas, low irritation, soft and harmonious smoke. Some of its chemical components are as follows:

[0101]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com