Formula of essence for heat-not-burn cigarette

A heat-not-burn and cigarette technology, applied in the direction of essential oils/spices, tobacco, applications, etc., can solve the problems affecting the smoking experience, and achieve the effects of easy access, enhanced cigarette aroma, and low irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

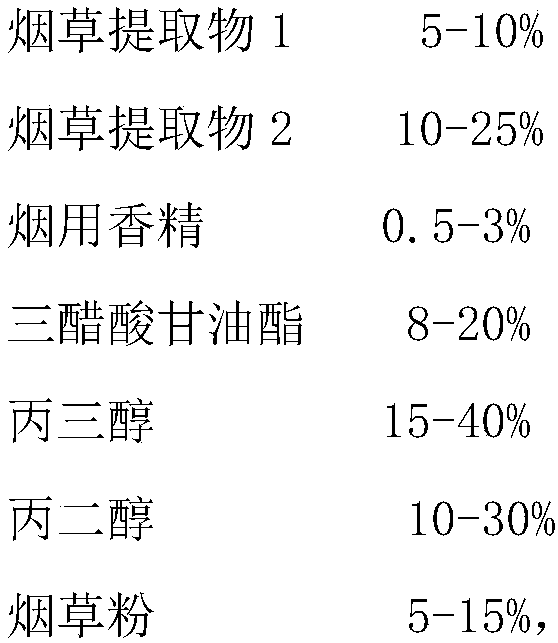

[0022] Flavor ratio (by mass percentage) suitable for heat-not-burn cigarettes of the present invention

[0023]

[0024] The embodiment of tobacco extract 1: get tobacco raw materials including shredded tobacco and shredded stems, pulverize through a pulverizer, sieve and select particles with a mesh number of 40-60 mesh, add water and ethanol mixed solvent (mass ratio : water / ethanol = 2:1), fully stirred, ultrasonic extraction, ultrasonic extraction conditions: temperature 40°C, extraction time: 2h, ultrasonic frequency: 40KHZ, stand still for 15min after extraction, filter through 1mm particle size molecular sieve, collect the filtrate, Concentrate at 55°C, and the concentrate is tobacco extract 1.

[0025] The embodiment of tobacco extract 2: take a certain amount of extract 1, add distilled water according to the solid-liquid ratio of 1:1.2, stir evenly, according to the volume ratio of 70%, slowly add 95% ethanol while stirring, under airtight conditions, place in 0 ...

Embodiment 2

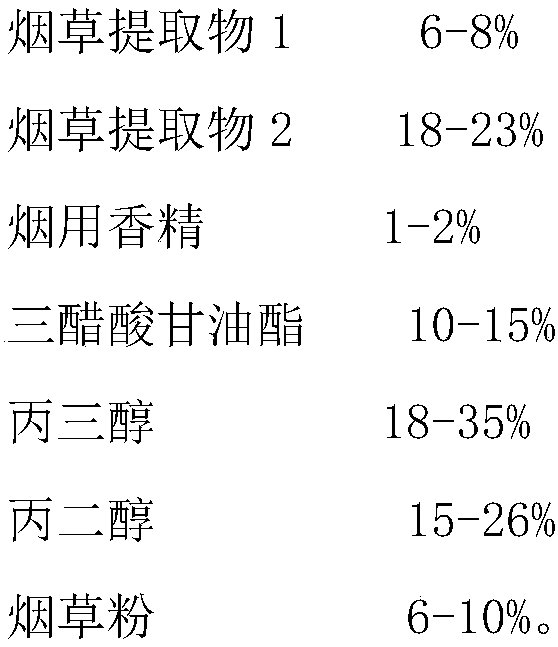

[0029] Flavor ratio (by mass percentage) suitable for heat-not-burn cigarettes of the present invention

[0030]

[0031] In Example 2 above, tobacco extract 1, tobacco extract 2, and tobacco powder can be obtained according to the method described in Example 1.

[0032] The above-mentioned tobacco flavor 2 is composed of the following components by mass percentage: 12% macrostigmatrienone, 8% ethyl vanillin, 3% ethyl maltol, 8% β-ionone, 7% solanone, Indole 2%, 2,3,5-trimethylpyrazine 2%, methyl dihydrojasmonate 7%, β-damascenone 5%, β-damascenone 10%, palmitic acid 2 %, 5% isoamyl isovalerate, 4% phenylethyl alcohol, 2% butyric acid, 8% dihydroactinolide, 9% dihydrocoumarin, and 6% oxidized isophorone.

[0033] Wherein, the above-mentioned tobacco powder is tobacco powder obtained by pulverizing and sieving shredded tobacco of air-cured and sun-cured tobacco. The air-cured tobacco is Burley tobacco, and the air-cured tobacco is oriental tobacco.

Embodiment 3

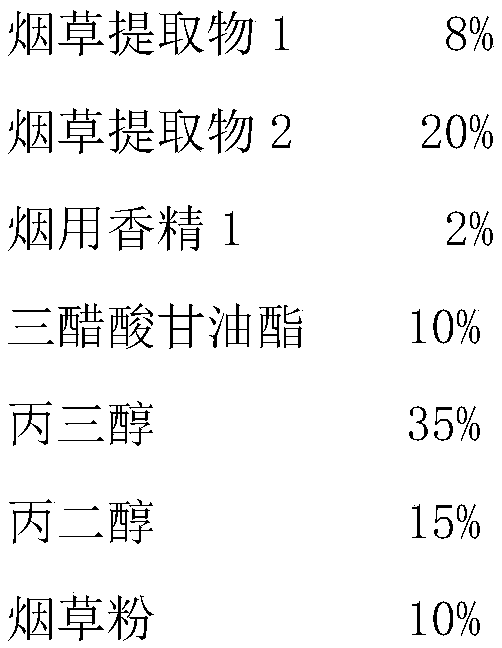

[0035] Flavor ratio (by mass percentage) suitable for heat-not-burn cigarettes of the present invention

[0036]

[0037] In the above Example 3, tobacco extract 1, tobacco extract 2, and tobacco powder can be obtained according to the method described in Example 1.

[0038] The above-mentioned tobacco flavor 2 is composed of the following components by mass percentage: 12% macrostigmatrienone, 8% ethyl vanillin, 3% ethyl maltol, 8% β-ionone, 7% solanone, Indole 2%, 2,3,5-trimethylpyrazine 2%, methyl dihydrojasmonate 7%, β-damascenone 5%, β-damascenone 10%, palmitic acid 2 %, 5% isoamyl isovalerate, 4% phenylethyl alcohol, 2% butyric acid, 8% dihydroactinolide, 9% dihydrocoumarin, and 6% oxidized isophorone.

[0039] Wherein, the above-mentioned tobacco powder is tobacco powder obtained by crushing and sieving shredded tobacco of flue-cured tobacco and sun-cured tobacco. The air-cured tobacco is burley tobacco, and the sun-cured tobacco is sun-cured yellow tobacco.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com