Method for reducing content of lignin in papermaking tobacco sheets

A technology of tobacco sheet and paper making method, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problems such as the application of imitated enzymes, large limitations, and quality effects, etc., and achieves reduced irritation, improved taste quality, and woodiness Air reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

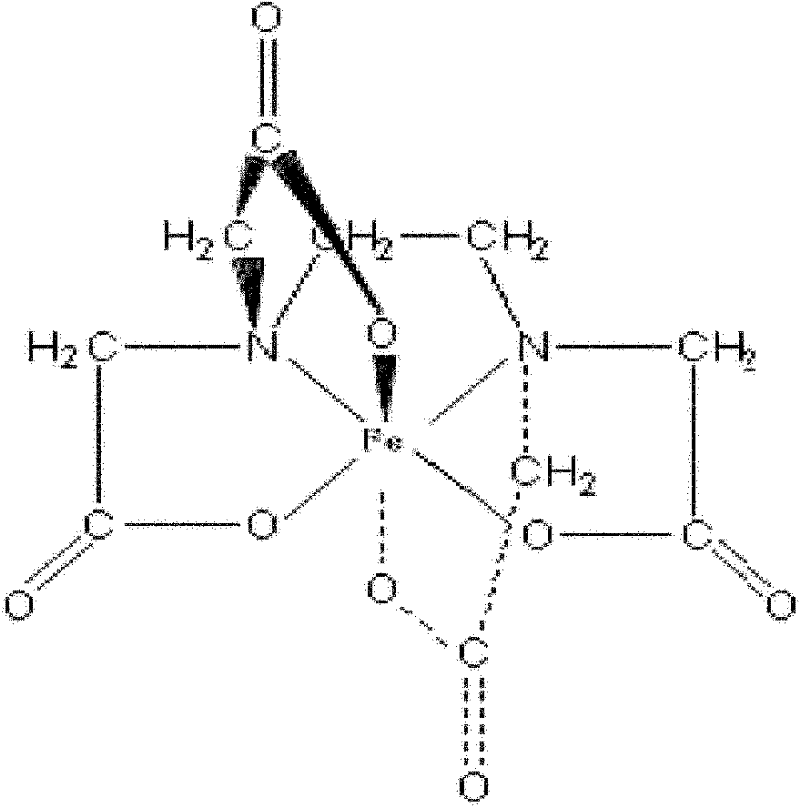

[0037] (1) Preparation of mimic enzyme: FeSO 4 ·7H 2 30% of O, 5% of citric acid, 5% of oxalic acid, and 60% of water are all percentages by mass. Carry out chelation compounding according to the above ratio, the temperature of the water is controlled at 45°C, and FeSO is added first 4 ·7H 2 O, stirring speed is 200 rpm, stirring for 3 minutes; then add citric acid, stirring speed is 700 rpm, stirring for 1 minute; then add oxalic acid, stirring speed is 200 rpm, stirring for 2 minutes, finally mix well spare.

[0038] (2) In the tobacco raw material pulping stage of the tobacco sheet preparation process, add the simulated enzyme prepared in the step (1) in the tobacco slurry according to the 1% ratio of the dry weight of the tobacco slurry substance, and measure the temperature of the tobacco slurry as 30°C, the processing time is controlled at 25min.

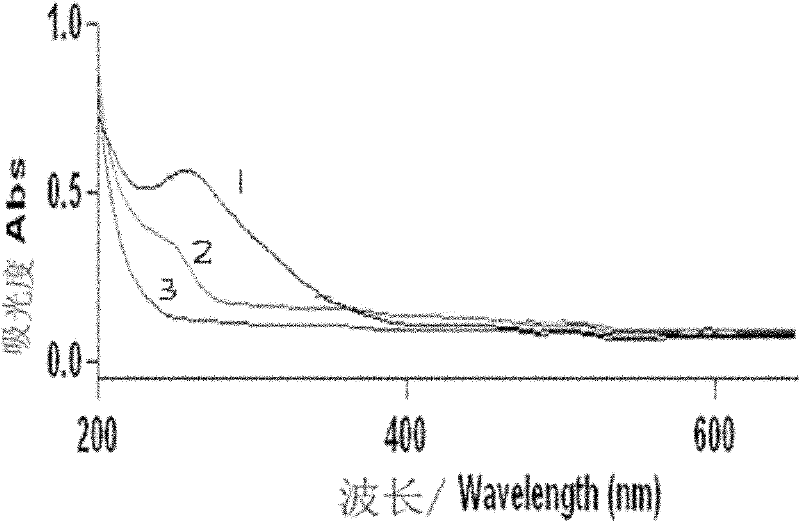

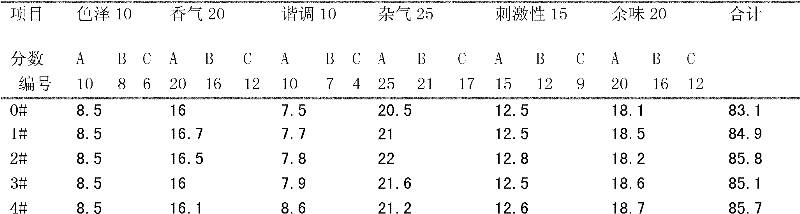

[0039] (3) After testing, after the simulated enzyme treatment, the lignin content in the tobacco pulp was reduced from...

Embodiment 2

[0041] (1) Preparation of mimic enzyme: FeSO 4 ·7H 2 25% O, 20% citric acid, 8% oxalic acid, and 47% water are all percentages by mass. Carry out chelation compounding according to the above ratio, the temperature of the water is controlled at 35°C, and FeSO is added first 4 ·7H 2 O, stirring speed is 250 rpm, stirring for 4 minutes; then add citric acid, stirring speed is 500 rpm, stirring for 3 minutes; then add oxalic acid, stirring speed is 100 rpm, stirring for 4 minutes, finally mix well spare.

[0042] (2) In the tobacco raw material pulping stage of the tobacco sheet preparation process, add the simulated enzyme prepared in (1) according to the 2.5% ratio of the dry weight of the tobacco pulp substance, measure the temperature of the tobacco pulp to be 35 ° C, and control the treatment time In 30min.

[0043] (3) It was tested that after the tobacco stems and shreds were treated by the simulated enzyme system, the lignin content in the tobacco pulp was reduced fro...

Embodiment 3

[0045] (1) Preparation of mimic enzyme: FeSO 4 ·7H 2 35% of O, 12% of citric acid, 9% of oxalic acid, and 44% of water are all percentages by mass. Carry out chelation compounding according to the above ratio, the temperature of the water is controlled at 40°C, and FeSO is added first 4 ·7H 2 O, stirring speed is 280 rpm, stirring for 5 minutes; then add citric acid, stirring speed is 670 rpm, stirring for 2 minutes; then add oxalic acid, stirring speed is 150 rpm, stirring for 5 minutes, finally mix well spare.

[0046] (2) In the tobacco raw material pulping stage of the tobacco sheet preparation process, add the simulated enzyme prepared in (1) according to the 3% ratio of the dry weight of the tobacco pulp substance, measure the temperature of the tobacco pulp to be 32 ° C, and control the treatment time at 32min.

[0047] (3) After testing, after the tobacco stems and shreds were treated by the simulated enzyme system, the lignin content in the tobacco pulp was reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com