Preparation method of tobacco fiber for cigarette paper

A technology of tobacco fiber and manufacturing method, which is applied in the field of cigarette paper manufacturing, can solve the problems of poor matching between the color of cigarette paper and cigarette style, heavy wood odor, etc., so as to improve the use value, reduce the wood odor, and improve the matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

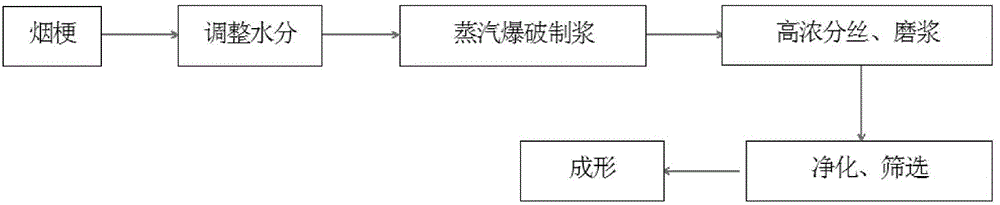

[0012] Such as figure 1 As shown, select 1 kg of flue-cured tobacco stem raw material, adjust its moisture content to 10% (mass percentage), send the tobacco stems into the steam explosion pulping system, utilize the steam explosion pulping system, and use saturated water vapor at a pressure of 0.8 Keep the explosion pulping under MPa for 40s, adjust the mass percentage concentration of the obtained explosion pulp to 26%, use high-consistency disc mill for high-consistency shredding and refining, and then purify and screen to obtain tobacco fiber pulp. The tobacco fiber slurry can be further processed by cigarette paper production enterprises to meet the production requirements of cigarette paper. The tobacco fiber slurry is added into the cigarette paper slurry according to the mass fraction of 20% of the cigarette paper slurry, and the tobacco fiber commercial pulp sheet or other forms of tobacco fiber cigarette paper are prepared by a pulp board machine or other forming equ...

Embodiment 2

[0014] Select 2 kg of discarded tobacco stems of a mixed type of cigarette, adjust its moisture content to 30%, use a steam explosion pulping system, use saturated water vapor, keep blasting pulp under a pressure of 3.0 MPa for 5 seconds, and adjust the concentration of the resulting blasting pulp to 20 %, use the high-concentration disc mill to further carry out high-concentration shredding and refining treatment, after purification and screening, the tobacco fiber slurry is obtained, and the tobacco fiber slurry is added to the cigarette paper slurry at a mass fraction of 50% of the cigarette paper slurry , compounding cigarette paper, the obtained cigarette paper has the characteristic appearance of obvious tobacco color fiber. Cigarette paper using tobacco fiber and cigarette paper not using tobacco fiber, select a mixed type of cigarette shredded tobacco to make sample cigarettes respectively, and according to the sensory evaluation of professional smokers, the cigarette p...

Embodiment 3

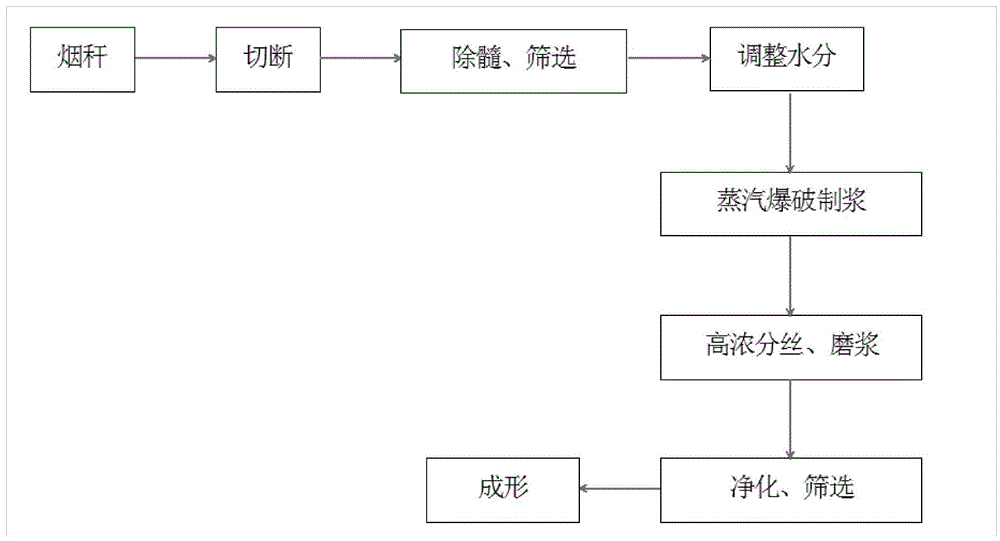

[0016] Such as figure 2 As shown, select 10 kg of air-dried tobacco rods, cut them off, and adjust their moisture content to 60% after removing pith and screening, use a steam explosion pulping system, use saturated water vapor, and maintain 15min explosion pulping under a pressure of 1.6MPa. The concentration of the obtained blasting pulp is adjusted to 20%, and the high-concentration disc mill is used for further high-concentration shredding and refining treatment, and then purified and screened to obtain tobacco fiber pulp. The tobacco fiber slurry is added into the cigarette paper slurry according to 10% of the mass fraction of the cigarette paper slurry, and the tobacco fiber commodity pulp sheet or other forms of tobacco fiber cigarette paper are prepared by a pulp sheet machine or other forming equipment. The resulting cigarette paper has a characteristic appearance of distinct tobacco colored fibers. Cigarette paper using tobacco fiber and cigarette paper not using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com