Method for increasing smoking quality of papermaking-reconstituted slices

A technology of smoking quality and papermaking method, which is applied in the direction of preparation of tobacco, application, tobacco, etc., and can solve problems such as sensory quality defects of flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

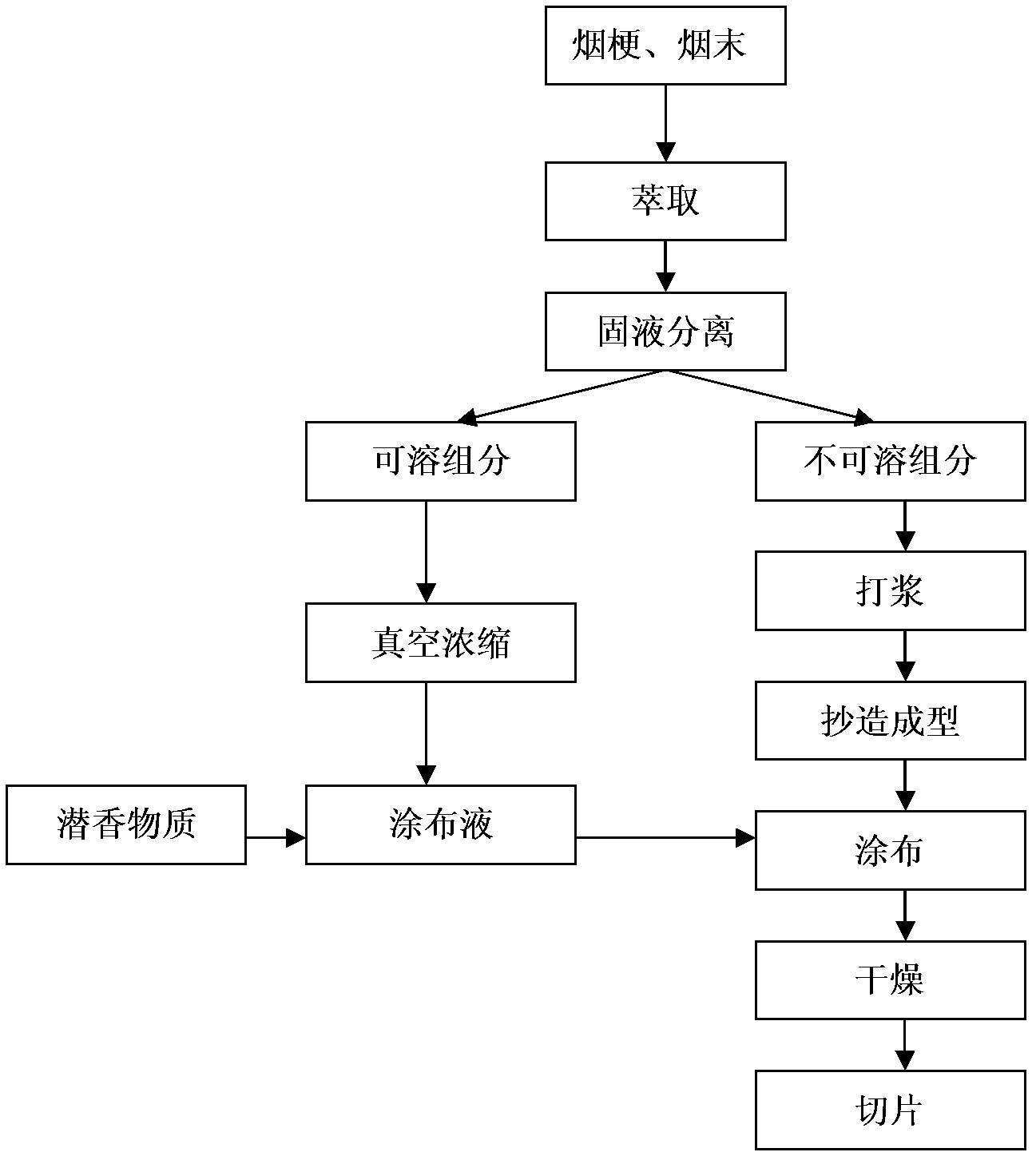

Method used

Image

Examples

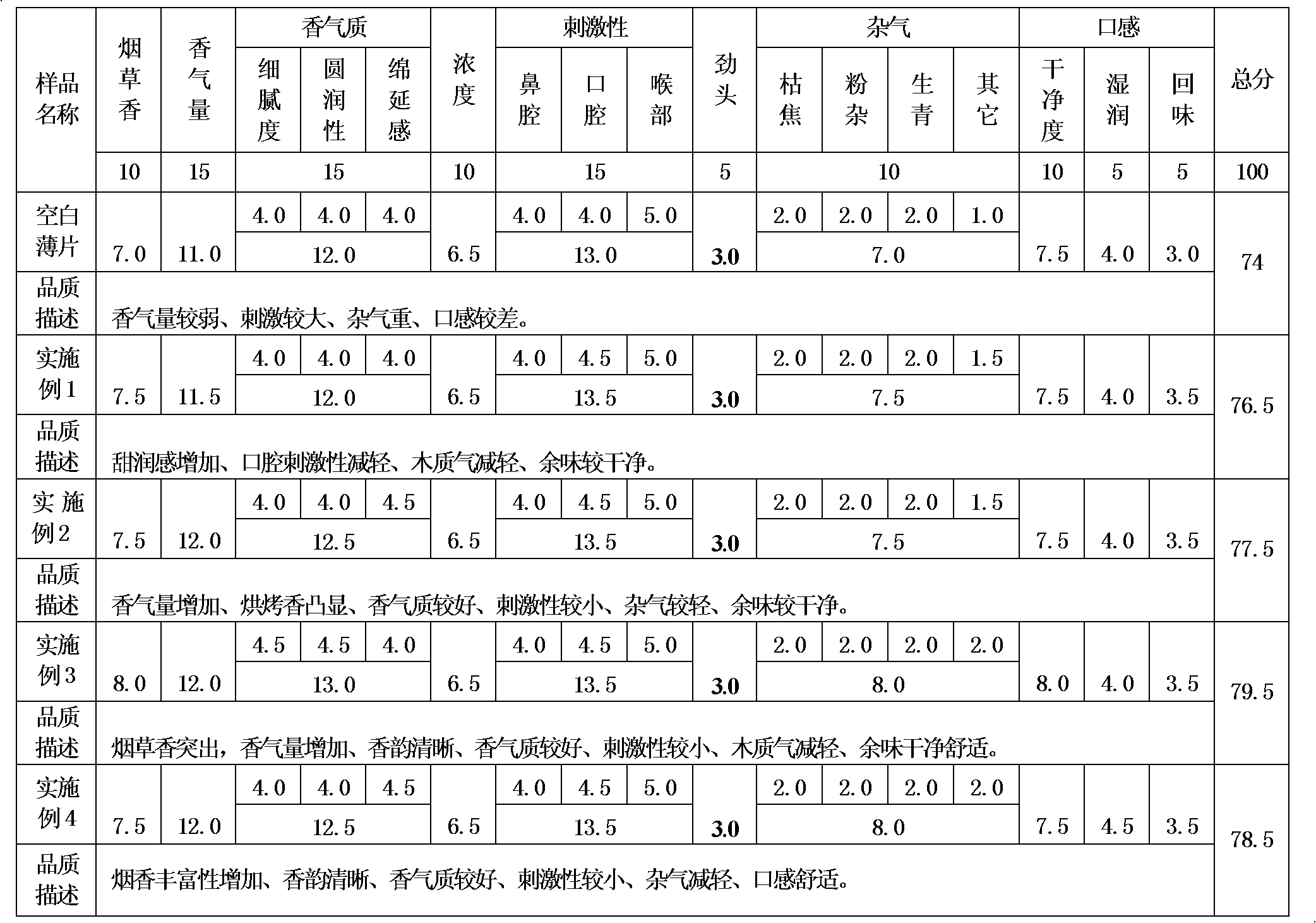

Embodiment 1

[0026] Get 0.5% of 4-methylpentanoic acid glucose tetraester, 0.08% of phenylethyl alcohol glucoside, 0.1% of proline Amadori compound, 0.3% of 3-oxo-α-ionol acetate, 1,2- Propylene glycol 1%, the above raw materials are mixed with the coating solution, and used in the preparation of tobacco sheets in the coating process. The prepared thin slices were cut into shreds and rolled into cigarette samples, and compared with the rolled samples of blank thin slice samples, the smoking evaluation results were shown in Table 1.

Embodiment 2

[0028] Get 0.5% glucose tetraester isobutyrate, 0.1% phenylethyl alcohol glucoside, 0.1% proline Amadori compound, 0.3% bis(3-oxo-α-ionol) oxalate, 1,2- Propylene glycol 2%, the above raw materials are mixed with the coating liquid, and used for the preparation of tobacco sheets in the coating process. All the other are the same as Example 1, and the results of smoking are shown in Table 1.

Embodiment 3

[0030] Take 0.5% of 4-methylpentanoic acid glucose tetraester, 0.08% of leaf alcohol glucoside, 0.1% of alanine Amadori compound, 0.3% of 3-oxo-α-ionol acetate, 1,2- Propylene glycol 3%, the above-mentioned raw materials are mixed with the coating solution, and used in the preparation of tobacco sheets in the coating process. All the other are the same as Example 1, and the results of smoking are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com