Method for preparing tobacco sheet through enzymolysis extraction-Maillard reaction composite technology

A technology of Maillard reaction and tobacco flakes, applied in tobacco, tobacco processing, application, etc., can solve the problems affecting the quality of tobacco flakes, strong irritating sensation, affecting the color of flakes, etc., to achieve soft aroma, weakened irritation, control The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

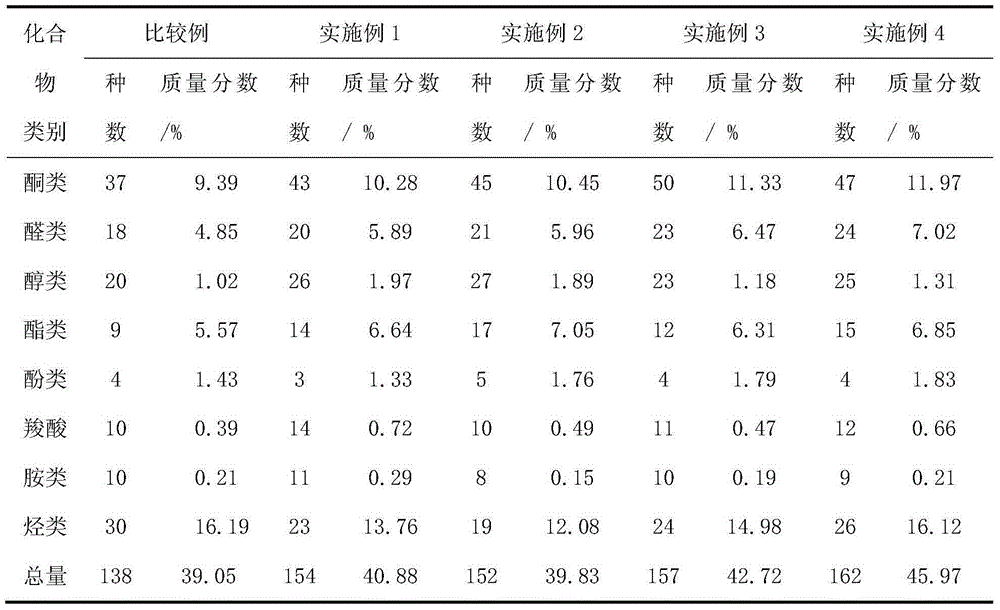

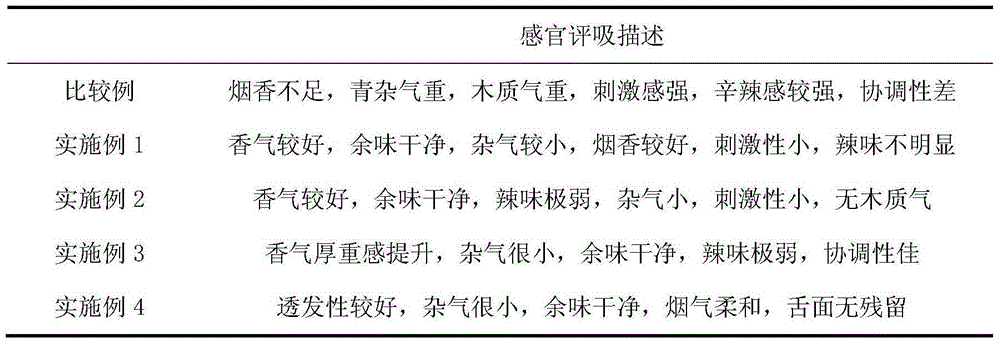

Examples

Embodiment 1

[0032] Step 1) Take 70kg of tobacco powder, add 930kg of water to the tobacco powder to form a mixed solution, and heat the mixed solution to 50°C;

[0033] Step 2) Add 3kg of pectinase to the mixture, keep stirring at 50°C for enzymolysis, carry out the enzymolysis process in a closed environment for 2 hours, then stop heating to obtain an enzymolysis solution;

[0034] Step 3) filtering the enzymolysis solution to obtain filtrate and solid raw material residue;

[0035] Step 4) carry out vacuum concentration to filtrate, be concentrated to 0.25m 3 , the gained water is added to step 1) for recycling;

[0036] Step 5) add the xylose of 2.2kg in the concentrated filtrate, the proline of 0.3kg, the cysteine of 0.06kg, the glycine of 0.3kg, the phenylalanine of 0.4kg, adjust pH to 7.5, the Maillard reaction occurs when heated at a constant temperature of 70°C for 13 hours;

[0037] Step 6) cooling the Maillard reaction solution to room temperature, and adjusting the pH to 4...

Embodiment 2

[0041]Step 1) Take 70kg of tobacco powder, add 930kg of water to the tobacco powder to form a mixed solution, and heat the mixed solution to 50°C;

[0042] Step 2) Add 2 kg of laccase to the mixture, keep constant temperature at 50°C and stir for enzymolysis, the enzymolysis process is carried out in a closed environment for 2 hours and then stop heating;

[0043] Step 3) filtering the enzymolysis solution to obtain filtrate and solid raw material residue;

[0044] Step 4) carry out vacuum concentration to filtrate, be concentrated to 0.25m 3 , the gained water is added to step 1) for recycling;

[0045] Step 5) add the xylose of 2.6kg in the concentrated filtrate, the proline of 0.34kg, the cysteine of 0.04kg, the glycine of 0.28kg, the phenylalanine of 0.38kg, adjust pH to 7.5, Maillard reaction occurs when heated at 70°C for 13 hours;

[0046] Step 6) Cool the Maillard reaction solution to room temperature, and adjust the pH to 4.68 with citric acid;

[0047] Step 7) ...

Embodiment 3

[0050] Step 1) Take 70kg of tobacco powder, add 930kg of water to the tobacco powder to form a mixed solution, and heat the mixed solution to 50°C;

[0051] Step 2) Add 3kg of pectinase and 0.5kg of laccase to the mixture, keep stirring at 50°C for enzymolysis, and carry out the enzymolysis process in a closed environment for 2 hours, then stop heating;

[0052] Step 3) filtering the enzymolysis solution to obtain filtrate and solid raw material residue;

[0053] Step 4) carry out vacuum concentration to filtrate, be concentrated to 0.25m 3 , the gained water is added to step 1) for recycling;

[0054] Step 5) in the concentrated filtrate, add the xylose of 2.5kg, the proline of 0.36kg, the cysteine of 0.05kg, the glycine of 0.26kg, the phenylalanine of 0.36kg, adjust pH to 7.5, Maillard reaction occurs when heated at 70°C for 13 hours;

[0055] Step 6) Cool the Maillard reaction solution to room temperature, and adjust the pH to 4.74 with citric acid;

[0056] Step 7) M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com