Method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco

A technology for reconstituting tobacco leaves and flue-cured tobacco, which is applied in the directions of preparation of tobacco, tobacco, and application, and can solve the problems of loss of tobacco aroma, weakened taste, and insufficient aroma of reconstituted tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Using the method of the present invention to extract sun-cured red tobacco end material and flue-cured tobacco stem material respectively, and compare with the extract of sun-cured tobacco end material and flue-cured tobacco stem material without adding compound enzyme preparation, the details are as follows :

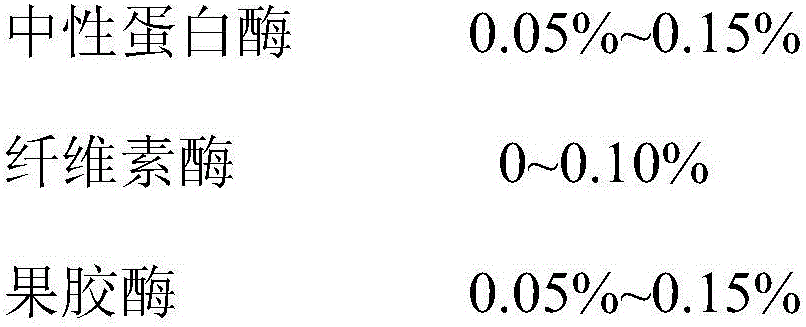

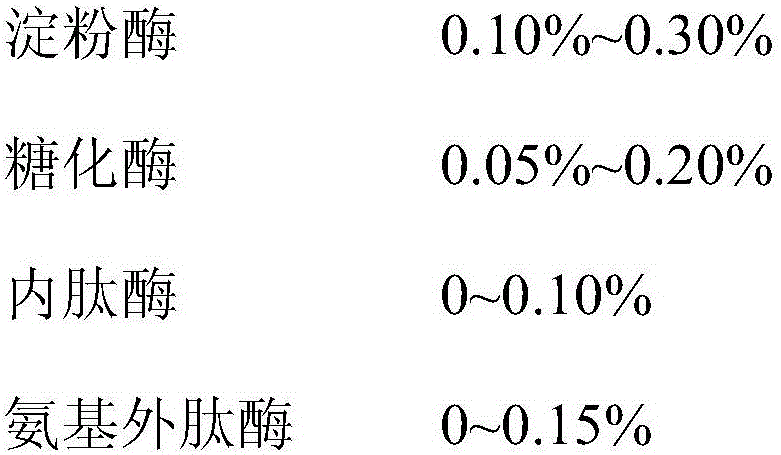

[0038] (1) Extraction of red sun-cured tobacco powder: add sun-cured smoke powder and water into the raw material extraction tank at a ratio of 1:4.5, and put in compound enzyme preparation and additives during the stirring process. Water extraction for 25-45 minutes at a temperature of 45-65°C, and then solid-liquid separation to obtain the extract of red-cured tobacco powder and solids of red-cured tobacco powder. The percentage by weight of smoke powder is shown in Table 1 below:

[0039] Table 1 Enzyme product filling ratio table of the implementation case of sun-cured tobacco powder

[0040]

[0041]

[0042] Extraction of red sun-cured t...

Embodiment 2

[0055] Embodiment 2: A kind of preparation method of the sun-cured red tobacco reconstituted tobacco leaf suitable for flue-cured tobacco flavor, it is characterized in that concrete steps are as follows:

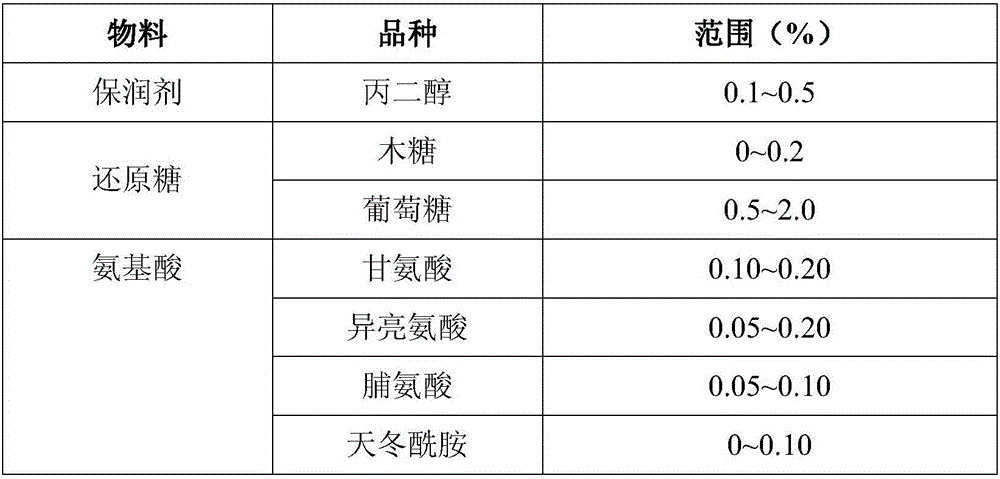

[0056] (1) In each embodiment, the red sun-cured tobacco end material extract and the sun-cured tobacco stem material extract were combined, and concentrated under reduced pressure to prepare a coating solution, and the residual enzyme was carried out in the concentration process and the reconstituted tobacco leaf drying process. Inactivate. At the same time, amino acids and other aroma-producing reaction catalysts are added to the concentration tank, and the percentages of additives such as sugar and amino acids added to the concentration tank in the total weight of the sun-cured red tobacco powder are as follows:

[0057] Table 5 Ratio of Additives such as Amino Acid in the Concentration Tank

[0058]

example 1

Example 2

Example 3

Example 4

E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com