Cobweb-shaped flexible strain sensor capable of identifying strain direction and preparation method thereof

A technology of strain sensor and strain direction, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, fiber type, etc., can solve the problems of mold limiting the economic benefits of industrial production, long cycle of flexible strain sensor, negative impact of environmental protection, etc. , to achieve the effects of large strain test range, improved conductivity, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

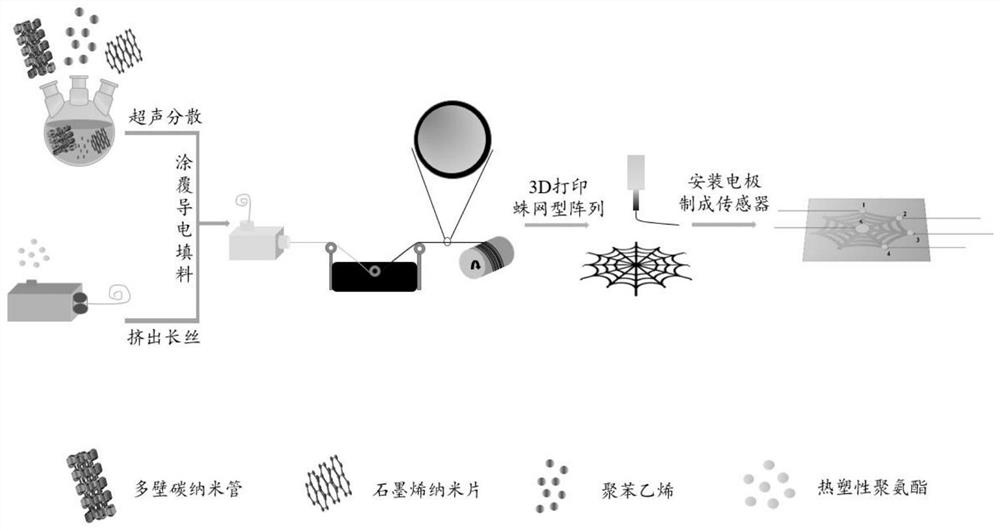

[0038] like figure 1 As shown, a spider web-shaped flexible strain sensor capable of identifying the strain direction of the present invention is prepared through the following steps:

[0039] Step 1: Mix the mixture of 0.07g of graphene nanosheets and 0.33g of multi-walled carbon nanotubes with 0.02g of polystyrene and 200ml of N,N-dimethylformamide solvent in a three-necked flask, and Ultrasonic dispersion for 1 hour in a water environment with 100W and an ultrasonic frequency of 4kHz to obtain a dispersion;

[0040] Step 2: Put the granular thermoplastic polymer after drying at room temperature for 24 hours into a single-screw extruder, and extrude pure thermoplastic polymer filamentary filament at an extrusion temperature of 180°C and an extrusion speed of 10r / min;

[0041] Step 3: Use the winding roller traction device to pull the wire in step 2 through the dispersion in step 1 at a constant speed, forming a uniform and thin conductive layer on its surface. After it is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com