Modified silver thick film sizing agent for crystalline silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. and other problems, to achieve the effect of improving the agglomeration state, improving the mechanical strength, and improving the light conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

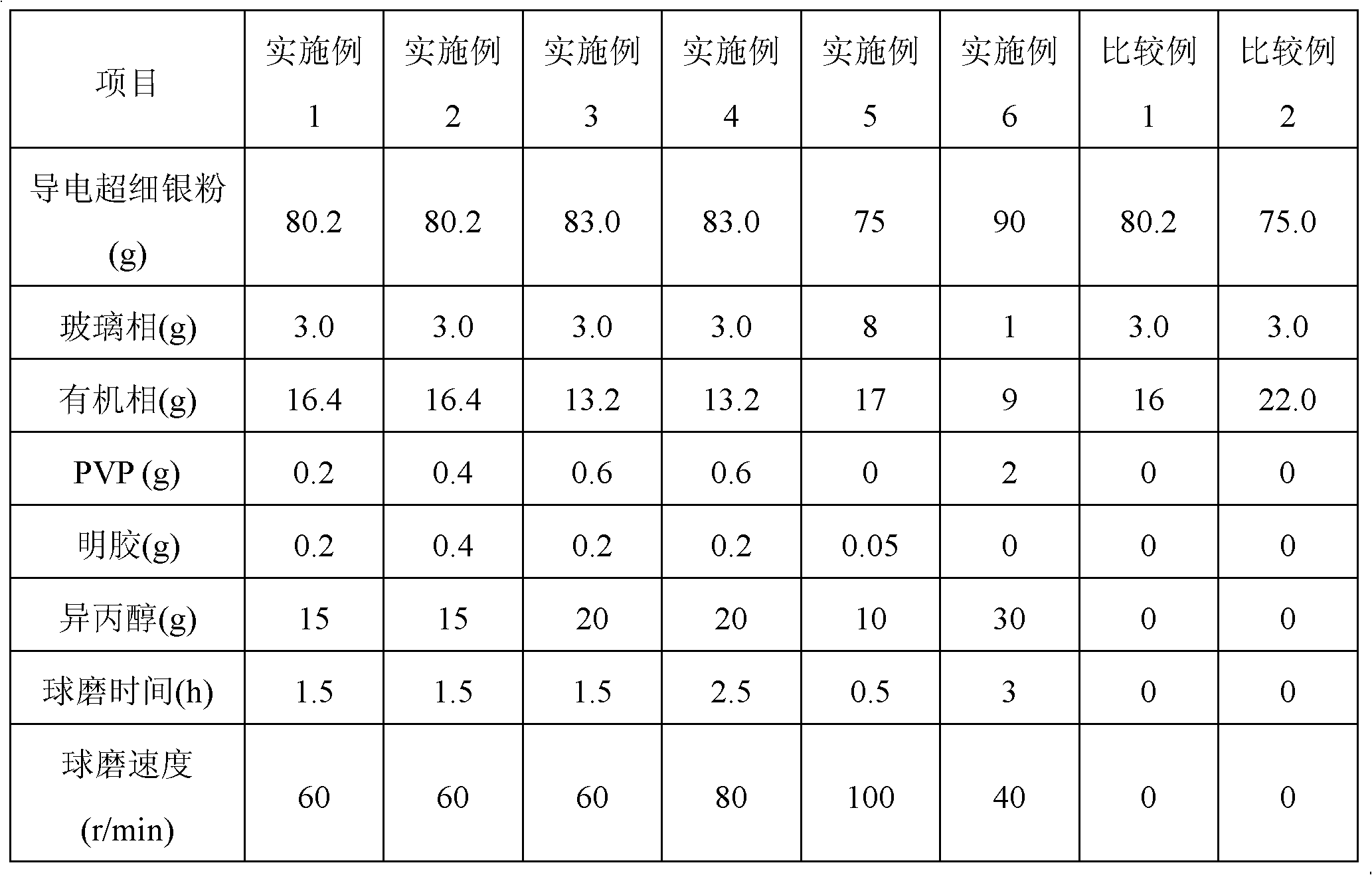

[0034] The present invention also provides a preparation method of the above-mentioned silver thick film paste for crystalline silicon solar cells, comprising the following steps:

[0035] (1) The conductive ultrafine silver powder, glass powder and surfactant are carried out ball milling pretreatment, ball milling speed is 40-100r / min, is preferably 60-80r / min; Ball milling time is 0.5-3h, is preferably 1.5- 2.5h; then filter and dry to obtain the ball milling pretreatment product;

[0036] (2) Mixing and rolling the ball-milling pretreatment product with the organic phase to obtain silver thick-film paste for modified crystalline silicon solar cells.

[0037] In the above technical solution, the ball milling medium used in the ball milling pretreatment is agate ball milling beads.

[0038] In the above technical scheme, during the ball milling pretreatment, a ball milling aid is also added, and the addition amount of the ball milling aid is 10-30% of the total weight of the...

Embodiment 1~6

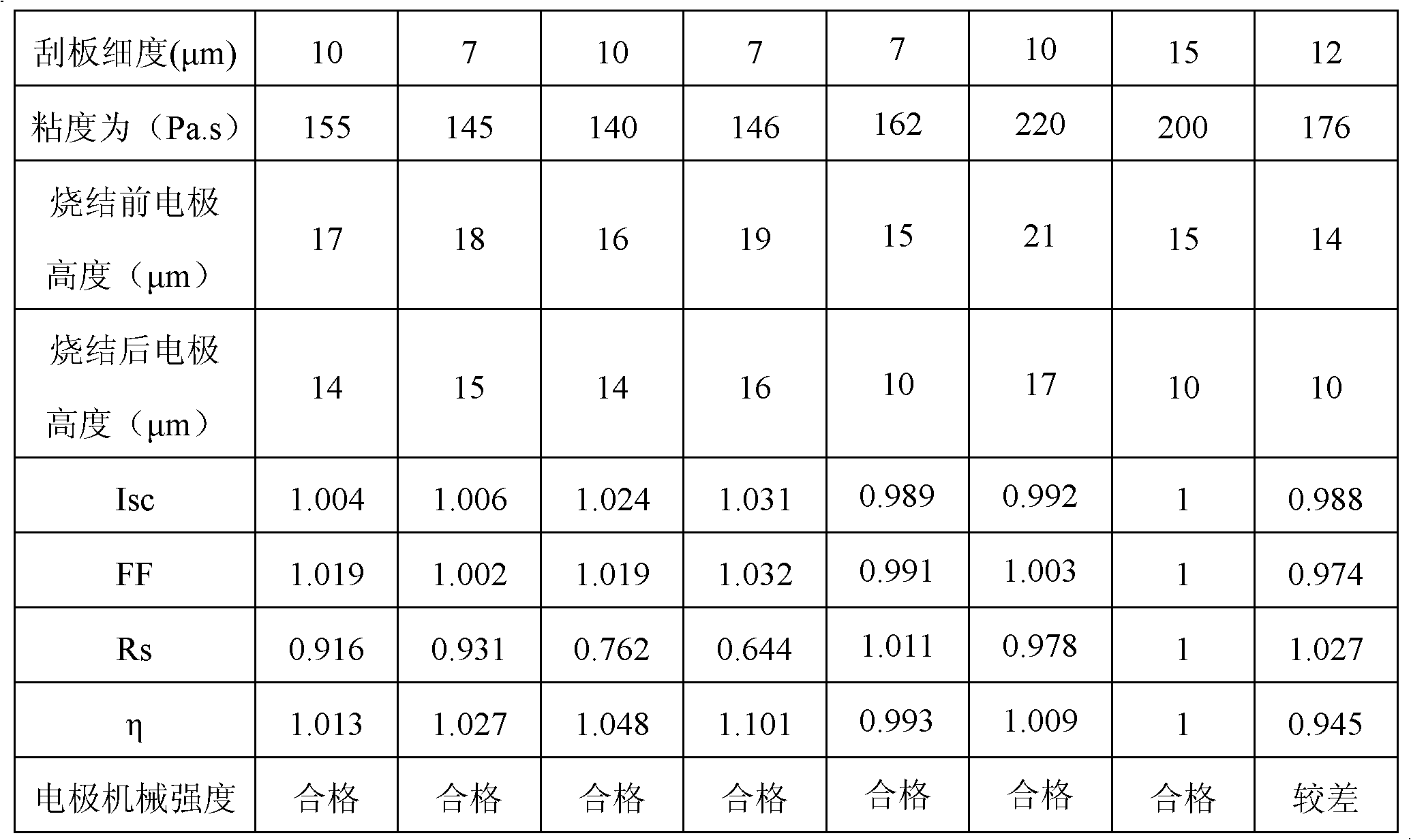

[0041] Add conductive ultra-fine silver powder (average particle size: 2.5 μm), glass powder, PVP (brand PVP40), gelatin (analytical grade), isopropanol and agate ball milling beads into a ball milling tank for ball milling, take out the materials, and dry them under vacuum at 40°C Back with organic phase (organic phase is terpineol in embodiment 1-4: ethyl cellulose=10: 1wt / wt; Organic phase is butyl carbitol in embodiment 5: ethyl cellulose=20: 1wt / wt; the organic phase in embodiment 6 is citric acid ester: methyl cellulose=5: 1wt / wt) premixes in mixer, mixes and rolls on three-roll machine then, obtains silver thick-film slurry, uses scraper The scraper fineness of the slurry was tested with a plate fineness meter, and the viscosity was measured with a viscometer (Brookfield HBT / 10 rpm, 25° C.). Use this slurry to make the front electrode of the solar cell by screen printing, prepare the solar cell according to the conventional method, and measure its fill factor FF, serie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com