Modified polyvinyl alcohol hydrogel material, special die, preparation method and application

A technology of polyvinyl alcohol and polyvinyl alcohol solution, which is applied in the fields of medical science and prostheses, can solve problems such as interface problems between multilayer materials, inappropriate pore structure, and low pore connectivity, so as to enhance biological activity and enhance Mechanical properties, growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

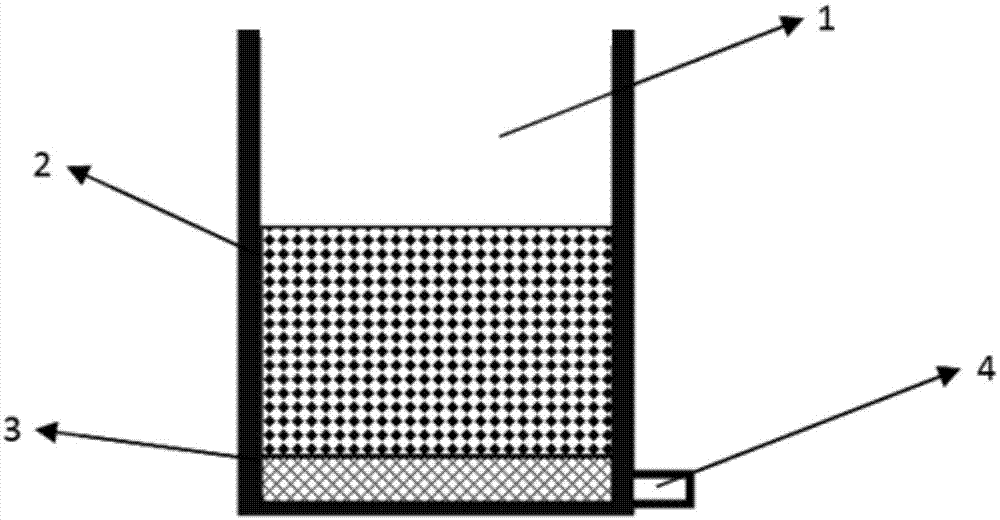

[0043] A special mold for preparing modified polyvinyl alcohol hydrogel material, the cavity is provided with a filter 3, the filter 3 divides the cavity into upper and lower cavities, the bottom of the lower cavity is provided with an air outlet 4, and the upper cavity The body is equipped with a soluble porogen 2, and a liquid storage cavity 1 is reserved on the top of the porogen 2.

[0044] A kind of preparation for preparing modified polyvinyl alcohol hydrogel material comprises the steps:

[0045] Step 1, preparation of polyvinyl alcohol solution and polyvinyl alcohol / polyoxymethylene blended suspension

[0046] Preparation method: prepare a solution of polyvinyl alcohol and 80% DMSO solution with a mass ratio of 15:85, and stir at 110°C for 3 hours to obtain a polyvinyl alcohol solution.

[0047] Prepare a solution of polyvinyl alcohol, 80% DMSO solution and polyoxymethylene in a mass ratio of 15:85:15, and stir at 110° C. for 3 hours to obtain a polyvinyl alcohol / poly...

Embodiment 2

[0061] Step 1, preparation of polyvinyl alcohol solution and polyvinyl alcohol / nylon 6 blended suspension

[0062] Preparation method: Prepare a solution with a mass ratio of polyvinyl alcohol to aqueous solution of 15:85, and stir at 98°C for 8 hours to obtain a polyvinyl alcohol solution.

[0063] A solution of polyvinyl alcohol, 80% DMSO solution, and nylon 6 with a mass ratio of 15:85:15 was prepared, and stirred at 110° C. for 3 hours to obtain a polyvinyl alcohol / nylon 6 blended suspension.

[0064] Step 2. Dispersion of micro-nano hydroxyapatite powder

[0065] Disperse micro-nano hydroxyapatite in deionized water, put it into an ultrasonic disperser, and disperse ultrasonically for 30 minutes, then inject it into the prepared polyvinyl alcohol solution, and continue stirring.

[0066] Step 3, Bubble Treatment of Blended Suspension

[0067] Put the blended suspension of polyvinyl alcohol / hydroxyapatite dissolved in step 2 under nitrogen protection at 95°C for 5 hours,...

Embodiment 3

[0077] Step 1, preparation of polyvinyl alcohol solution and polyvinyl alcohol / polyether ether ketone blended suspension

[0078] Preparation method: prepare a solution of polyvinyl alcohol and 80% DMSO solution with a mass ratio of 15:85, and stir at 100°C for 5 hours to obtain a polyvinyl alcohol solution.

[0079] A solution of polyvinyl alcohol, 80% DMSO solution and polyether ether ketone with a mass ratio of 15:85:15 was prepared, and stirred at 110° C. for 3 hours to obtain a polyvinyl alcohol / polyether ether ketone blended suspension.

[0080] Step 2. Dispersion of micro-nano bioactive glass powder

[0081] Disperse micro-nano bioactive glass in 80% DMSO solution, put it into an ultrasonic disperser, ultrasonically disperse for 30 minutes, then inject it into the prepared polyvinyl alcohol solution, and continue stirring.

[0082] Step 3, Bubble Treatment of Blended Suspension

[0083] Put the blended suspension of polyvinyl alcohol / bioactive glass dissolved in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com