Preparation method for low temperature toughness isotatic polypropylene product

A technology of isotactic polypropylene and low-temperature toughness, which is applied in the field of preparation of toughened polypropylene and tactic polypropylene products, can solve the problems of limited effect, insignificant reduction in modulus and tensile strength, etc., and reach the glass transition temperature Low, reduced strength and processing fluidity, good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

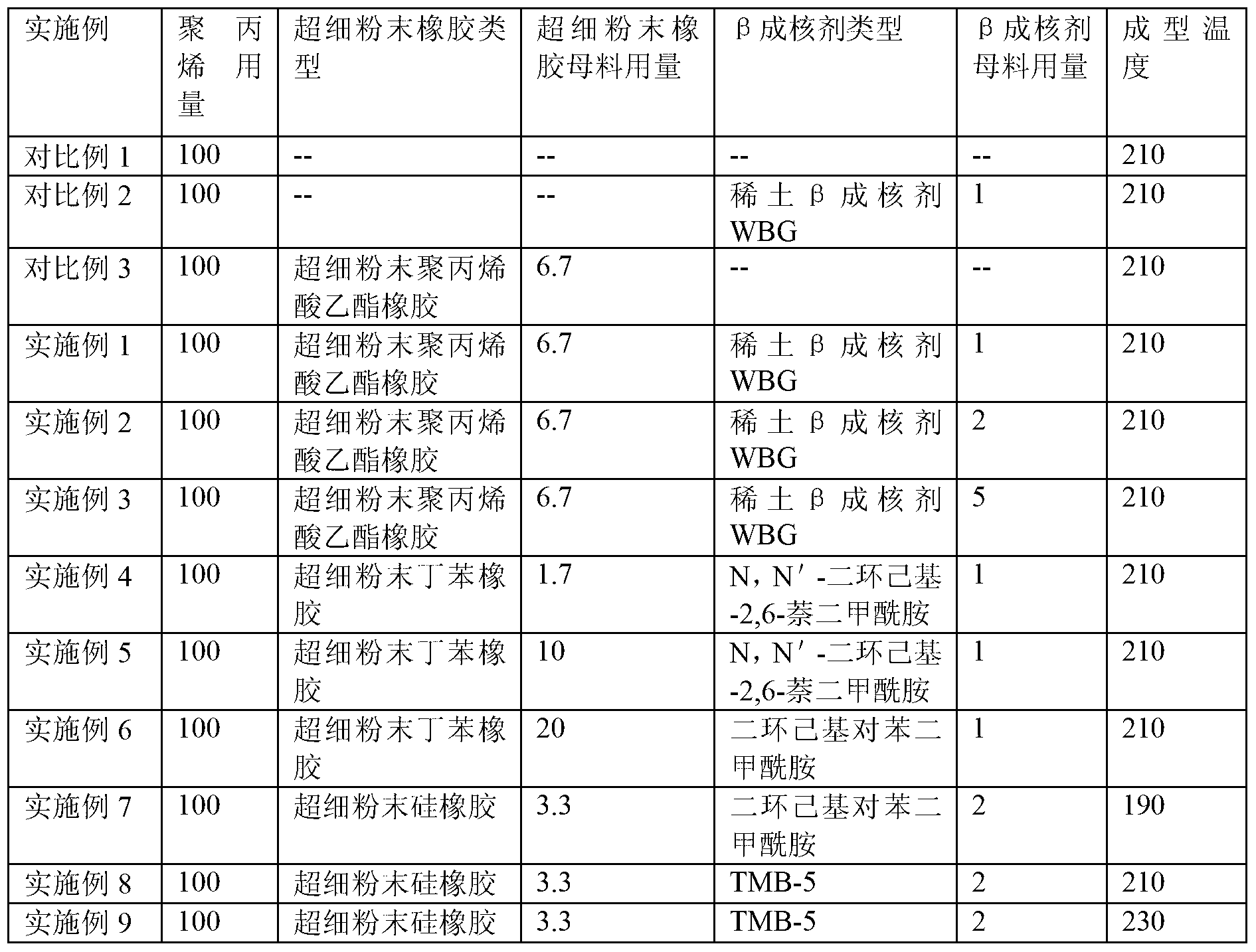

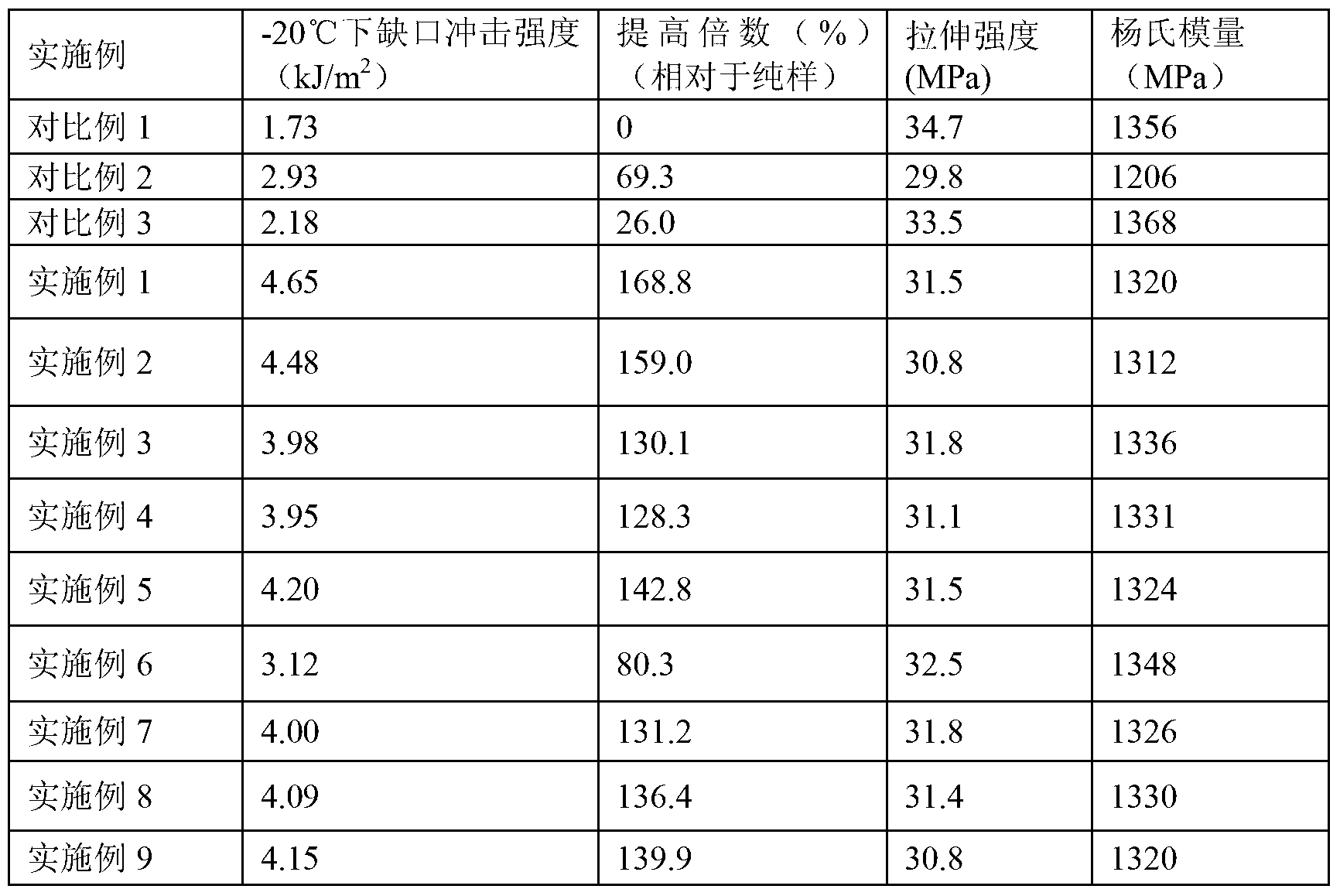

Embodiment 1

[0023] First, premix 100 parts of isotactic polypropylene resin and 5 parts of rare earth β-nucleating agent WBG and then add them to the twin-screw extruder. , 200°C, 200°C, 200°C, 195°C, the same below, omitted) to obtain β-nucleating agent masterbatch by melt blending, extrusion, cooling, and pelletizing; 100 parts of isotactic polypropylene resin, 30 parts of superfine The powder polyethyl acrylate rubber is pre-mixed and added to the twin-screw extruder at a temperature of 150-200°C (the temperature of each zone of the twin-screw extruder is 150°C, 190°C, 200°C, 200°C, 200°C, 195°C , the same below, omitted) under melt blending extrusion, cooling, pelletizing to obtain ultra-fine powder polyethylacrylate rubber masterbatch; 1 part of β-nucleating agent masterbatch, 6.7 parts of ultrafine powder polyethylacrylate rubber Ester rubber masterbatch, 100 parts of isotactic polypropylene resin and 0.1 part of antioxidant 1010 are pre-mixed and then added to the twin-screw extrud...

Embodiment 2

[0025] 100 parts of isotactic polypropylene resin and 5 parts of rare earth β-nucleating agent WBG are pre-mixed and then added to the twin-screw extruder, melted, blended and extruded at a temperature of 150-200 ° C, cooled, and pelletized to obtain β-nucleated Agent masterbatch; premix 100 parts of isotactic polypropylene resin and 30 parts of ultra-fine powdered polyethylacrylate rubber, then add it to a twin-screw extruder, melt blend and extrude at a temperature of 150-200 ° C, cool and cut Get superfine powder polyethyl acrylate rubber masterbatch; 2 parts of β nucleating agent masterbatch, 6.7 parts superfine powder polyethylacrylate rubber, 100 parts isotactic polypropylene resin and 0.1 part antioxidant After 1010 premixing, add it to the twin-screw extruder, melt blending and extruding at a temperature of 150-200 ° C, cool, and pelletize to obtain isotactic polypropylene modified pellets; the prepared isotactic polypropylene modified pellets The materials were inject...

Embodiment 3

[0027] 100 parts of isotactic polypropylene resin and 5 parts of rare earth β-nucleating agent WBG are pre-mixed and then added to the twin-screw extruder, melted, blended and extruded at a temperature of 150-200 ° C, cooled, and pelletized to obtain β-nucleated Agent masterbatch; premix 100 parts of isotactic polypropylene resin and 30 parts of ultra-fine powdered polyethylacrylate rubber, then add it to a twin-screw extruder, melt blend and extrude at a temperature of 150-200 ° C, cool and cut Get superfine powder polyethyl acrylate rubber masterbatch; 5 parts of beta nucleating agent masterbatch, 6.7 parts superfine powder polyethylacrylate rubber masterbatch, 100 parts of isotactic polypropylene resin and 0.1 part of antibacterial Oxygen agent 1010 is pre-mixed and added to a twin-screw extruder, melt-blended and extruded at a temperature of 150-200°C, cooled, and pelletized to obtain isotactic polypropylene modified pellets; the obtained isotactic polypropylene is modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com