Micro-foaming low-dielectric cyanate ester resin and preparation method thereof

A technology of cyanate resin and electrocyanate, applied in the field of materials, can solve the problems of reducing the dielectric property of cyanate resin, not checking, sacrificing the mechanical properties of the resin, etc., and achieve good wave transmission performance and excellent dielectric properties. , the effect of avoiding the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

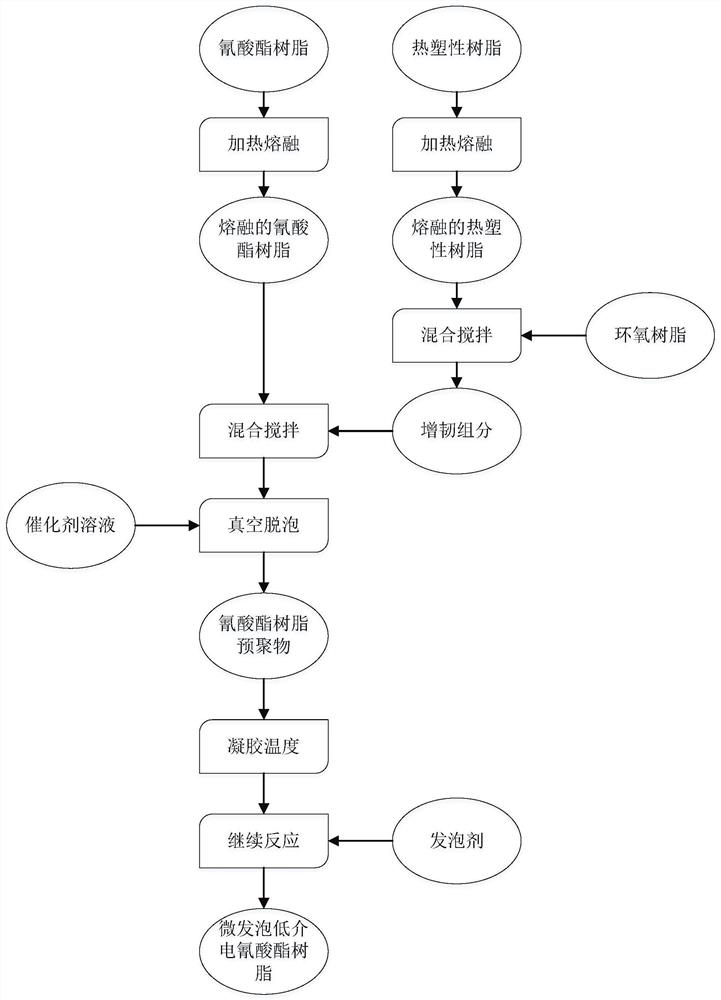

Method used

Image

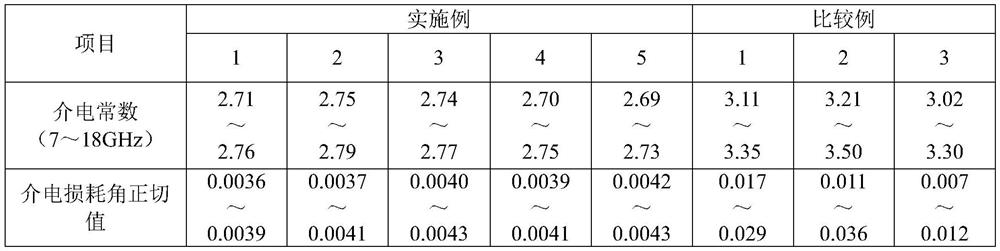

Examples

Embodiment 1

[0026] Proportioning (number of parts by mass):

[0027] Cyanate: bisphenol A type cyanate, 80 parts by weight;

[0028] Epoxy resin: bisphenol A type epoxy resin, 15 parts by weight;

[0029] Thermoplastic resin: polyethersulfone, 20 parts by weight, the molar ratio of cyanate functional group to terminal hydroxyl group is 25:1;

[0030] Foaming agent: azodicarbonamide, 3 parts by weight;

[0031] Catalyst solution: 1 part by weight; bis-n-butyltin oxide is the main catalyst, the concentration is 0.7%; nonylphenol is the auxiliary catalyst, the concentration is 15%; the solvent is dichloroethane.

[0032] Preparation Process:

[0033] In the first step, the cyanate resin is heated to 90-95°C and melted to a homogeneous liquid.

[0034] In the second step, the thermoplastic resin is heated to 105-110°C to melt, and then mixed with epoxy resin, fully stirred evenly to obtain a toughening component;

[0035] The third step is to mix the molten cyanate resin and the tougheni...

Embodiment 2

[0039] Proportioning (number of parts by mass):

[0040] Cyanate: bisphenol F type cyanate, 90 parts by weight;

[0041] Epoxy resin: bisphenol F type epoxy resin, 20 parts by weight;

[0042] Thermoplastic resin: polyethersulfone, 20 parts by weight, the molar ratio of cyanate functional group to terminal hydroxyl group is 18:1;

[0043] Foaming agent: azodicarbonamide, 5 parts by weight;

[0044] Catalyst solution: 2 parts by weight; bis-n-octyltin oxide is the main catalyst with a concentration of 1%; nonylphenol is an auxiliary catalyst with a concentration of 10%; the solvent is dichloromethane.

[0045] Preparation Process:

[0046] In the first step, the cyanate resin is heated to 115-120°C and melted to a uniform liquid.

[0047] In the second step, the thermoplastic resin is heated to 105-110°C to melt, and then mixed with epoxy resin, fully stirred evenly to obtain a toughening component;

[0048] The third step is to mix the molten cyanate resin and the toughen...

Embodiment 3

[0052] Proportioning (number of parts by mass):

[0053] Cyanate: bisphenol M type cyanate, 80 parts by weight;

[0054] Epoxy resin: aliphatic glycidyl ether epoxy resin, 5 parts by weight;

[0055] Thermoplastic resin: polyether ether ketone, 5 parts by weight, the molar ratio of cyanate functional group to terminal hydroxyl group is 25:1;

[0056] Foaming agent: 4'4-oxobisbenzenesulfonyl hydrazide, 0.25 parts by weight;

[0057] Catalyst solution: 0.5 parts by weight; bis-n-octyltin oxide is the main catalyst with a concentration of 0.8%; nonylphenol is an auxiliary catalyst with a concentration of 15%; the solvent is dichloromethane.

[0058] Preparation Process:

[0059] In the first step, the cyanate resin is heated to 115-120°C and melted to a uniform liquid.

[0060] In the second step, the thermoplastic resin is heated to 125-130°C to melt, and then mixed with epoxy resin, and fully stirred evenly to obtain a toughening component;

[0061] The third step is to mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com