Crosslinked, oil-resistant, low temperature-resistant, low-smoke, halogen-free and flame-retardant cable material and its preparation method

A flame retardant cable, low temperature resistance technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance and mechanical properties, poor combustion crust performance, mechanical properties and other problems, to achieve excellent electrical properties, excellent The effect of mechanical properties, excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

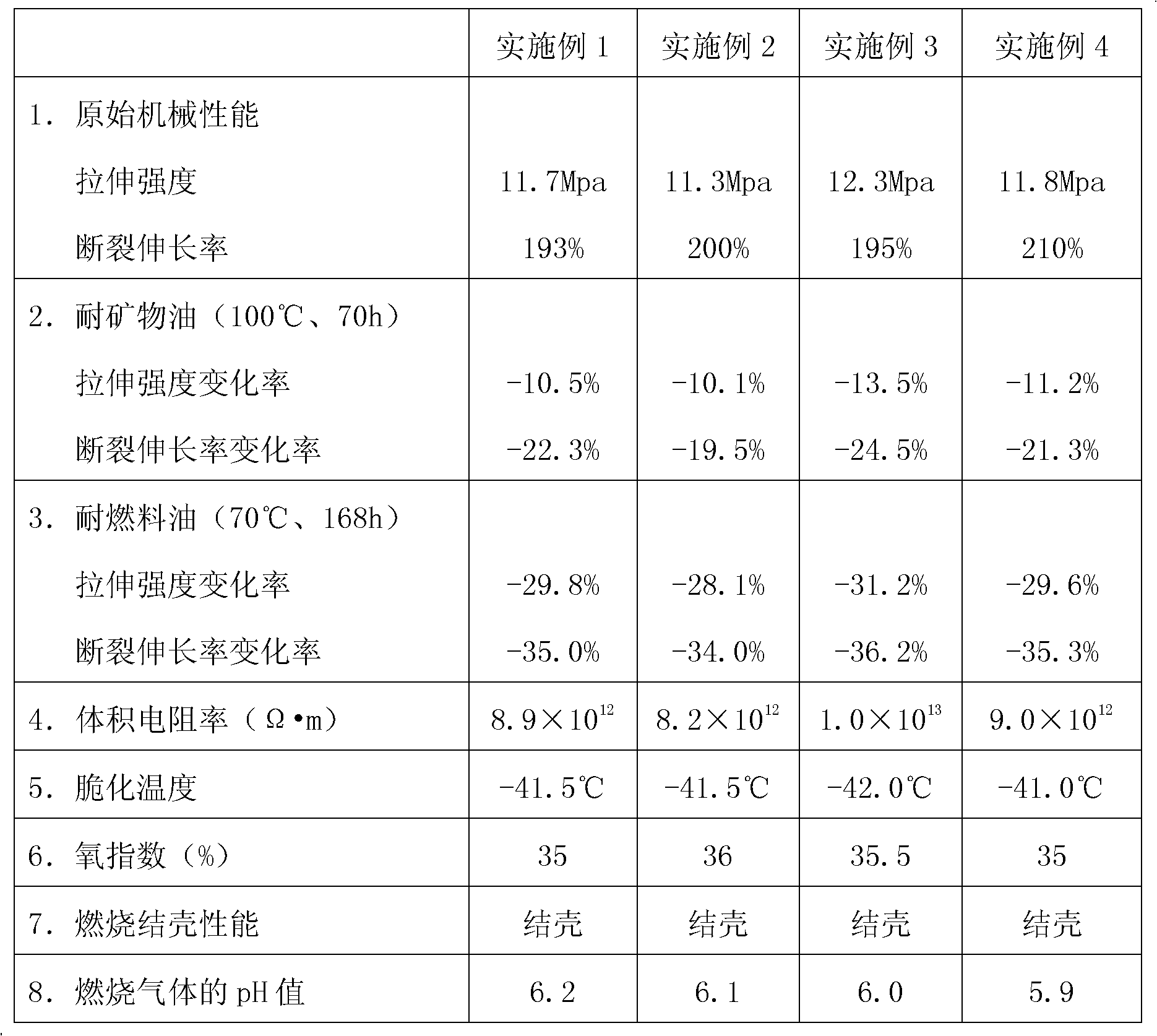

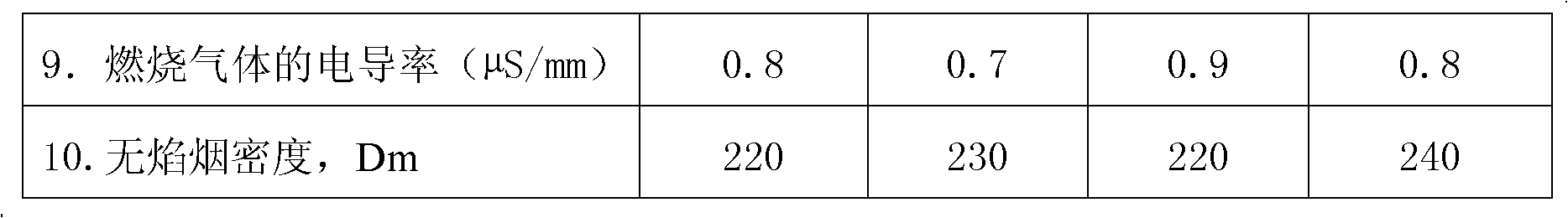

Examples

Embodiment 1

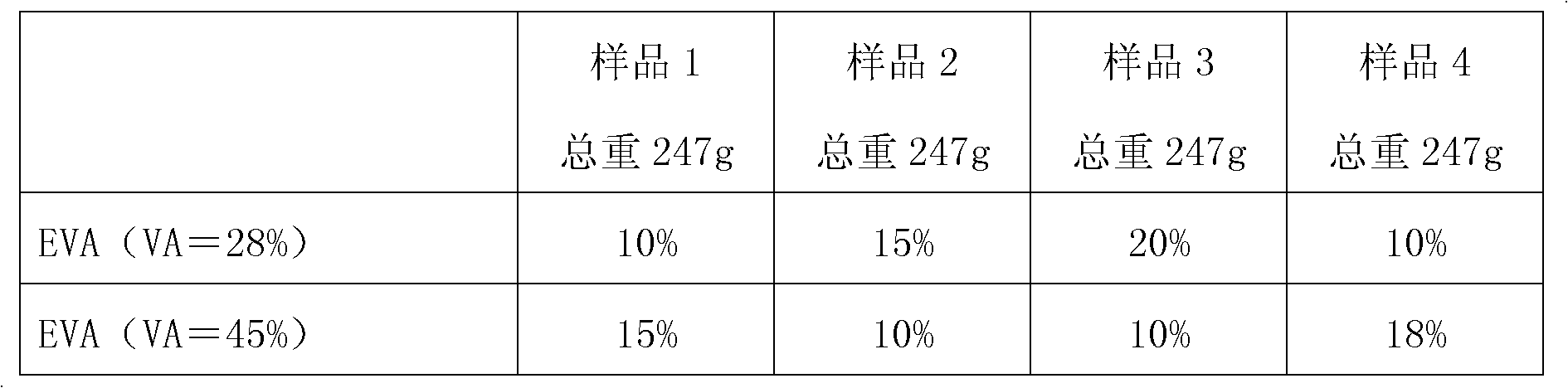

[0045] The preparation of the cross-linked oil-resistant and low-temperature resistant low-smoke halogen-free flame-retardant cable material in this embodiment includes the following steps:

[0046] 1) Weigh the raw materials according to the raw material components and corresponding weights of the cross-linked oil-resistant and low-temperature resistant low-smoke halogen-free flame-retardant cable material in Example 1 in Table 1.

[0047] 2) The raw materials weighed are placed in a high-speed mixer for mixing and stirring, and the mixing time is 5min, and then two times of extrusion granulation is carried out through a twin-screw extruder, and the temperature in the twin-screw extruder is 120-145°C.

[0048] The mixing speed of the high-speed mixer is 800rpm. The screw temperatures of each section starting from the feeding section in the twin-screw extruder are: 120°C, 125°C, 130, 135°C, 140°C, 145°C, 140°C, 135°C, 130°C.

[0049] 3) The granulated pellets are plasticized...

Embodiment 2

[0054] The preparation of the cross-linked oil-resistant and low-temperature resistant low-smoke halogen-free flame-retardant cable material in this embodiment includes the following steps:

[0055] 1) Weigh the raw materials according to the raw material components and corresponding weights of the cross-linked oil-resistant and low-temperature resistant low-smoke halogen-free flame-retardant cable material in Example 2 in Table 1.

[0056] 2) The raw materials weighed are placed in a high-speed mixer for mixing and stirring, and the mixing time is 8min, and then two times of extrusion granulation is carried out through a twin-screw extruder, and the temperature in the twin-screw extruder is 120-145°C.

[0057] The mixing speed of the high-speed mixer is 1000rpm. The screw temperatures of each section starting from the feeding section in the twin-screw extruder are: 120°C, 125°C, 130, 135°C, 140°C, 145°C, 140°C, 135°C, 130°C.

[0058] 3) The granulated pellets are plasticize...

Embodiment 3

[0063] The preparation of the cross-linked oil-resistant and low-temperature resistant low-smoke halogen-free flame-retardant cable material in this embodiment includes the following steps:

[0064] 1) Weigh the raw materials according to the raw material components and corresponding weights of the cross-linked oil-resistant and low-temperature resistant low-smoke halogen-free flame-retardant cable material in Example 3 in Table 1.

[0065] 2) The raw materials weighed are placed in a high-speed mixer for mixing and stirring, and the mixing time is 6min, and then two times of extrusion granulation is carried out through a twin-screw extruder, and the temperature in the twin-screw extruder is 120-145°C.

[0066] The mixing speed of the high-speed mixer is 800rpm. The screw temperatures of each section starting from the feeding section in the twin-screw extruder are: 120°C, 125°C, 130, 135°C, 140°C, 145°C, 140°C, 135°C, 130°C.

[0067] 3) The granulated pellets are plasticized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com