Elastomer for covering layer of fiber laminated flame-retardant conveyor belt used for coal mine and preparation method thereof

A conveyor belt and covering layer technology is applied in the field of fabric laminated flame-retardant conveyor belts for coal mines. Moderate performance, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

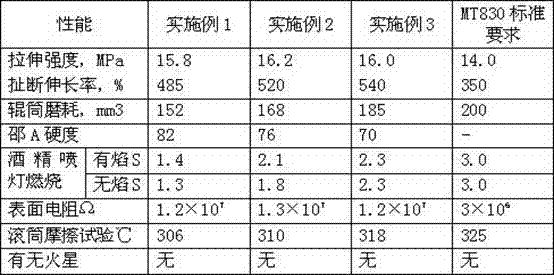

Examples

Embodiment 1

[0027] Put 50 kilograms of natural rubber, 40 kilograms of thermoplastic styrene-butadiene rubber, and 10 kilograms of modified chlorosulfonated polyethylene into an internal mixer or an open mill, and control the speed of 25-40r / min to blend for 1-3min;

[0028] Then add reinforcing agent: 30 kg of N220 carbon black, 10 kg of white carbon black, 10 kg of nano clay; silane coupling agent: 2 kg of SI-69; mixing for 1.5min-3min;

[0029] Add flame retardant: 10 kg of decabromine, 20 kg of 70% chlorinated paraffin, 8 kg of antimony trioxide, 15 kg of zinc borate, 20 kg of aluminum hydroxide, 20 kg of magnesium hydroxide; activator: 8 kg of zinc oxide, 2 kg of stearic acid; anti-aging agent: 1.5 kg of 4010Na, 1.5 kg of RD; mixing for 2min-5min;

[0030] Add flame retardant plasticizer: 10 kg of TPP; mix until 150°C-155°C for debinding;

[0031] After cooling and parking for 24 hours, put it into the internal mixer again to mix to 60°C, add accelerator: 1.0 kg of CZ, 0.8 kg of DM;...

Embodiment 2

[0034] Put 60 kilograms of natural rubber, 30 kilograms of thermoplastic styrene-butadiene rubber, 10 kilograms of modified chlorosulfonated polyethylene into an internal mixer or an open mill, and control the speed of 25-40r / min to blend for 1-3min;

[0035] Add reinforcing agent: 30 kg of N220 carbon black, 10 kg of white carbon black, 10 kg of nano clay; silane coupling agent: 2 kg of SI-69; mixing for 1.5min-3min;

[0036] Add flame retardant: 10 kg of decabromine, 20 kg of 70% chlorinated paraffin, 8 kg of antimony trioxide, 15 kg of zinc borate, 20 kg of aluminum hydroxide, 20 kg of magnesium hydroxide; activator: 8 kg of zinc oxide, 2 kg of stearic acid; anti-aging agent: 1.5 kg of 4010Na, 1.5 kg of RD; mixing for 2min-5min;

[0037] Add flame retardant plasticizer: 10 kg of TPP; mix until 150°C-155°C for debinding;

[0038] After cooling and parking for 24 hours, put it into the internal mixer again to mix to 60°C, add accelerator: 1.0 kg of CZ, 0.8 kg of DM; vulcaniz...

Embodiment 3

[0041]70 kilograms of natural rubber, 20 kilograms of thermoplastic styrene-butadiene rubber, and 10 kilograms of modified chlorosulfonated polyethylene were put into an internal mixer or an open mill, and the control speed was 25-40r / min and blended for 1-3min;

[0042] Then add reinforcing agent: 30 kg of N220 carbon black, 10 kg of white carbon black, 10 kg of nano clay; silane coupling agent: 2 kg of SI-69; mixing for 1.5min-3min;

[0043] Add flame retardant: 10 kg of decabromine, 20 kg of 70% chlorinated paraffin, 8 kg of antimony trioxide, 15 kg of zinc borate, 20 kg of aluminum hydroxide, 20 kg of magnesium hydroxide; activator: 8 kg of zinc oxide, 2 kg of stearic acid; anti-aging agent: 1.5 kg of 4010Na, 1.5 kg of RD; mixing for 2min-5min;

[0044] Add flame retardant plasticizer: 10 kg of TPP; mix until 150°C-155°C for debinding;

[0045] After cooling and parking for 24 hours, put it into the internal mixer again to mix to 60°C, add accelerator: 1.0 kg of CZ, 0.8 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com