Synthesizing method of high-ethylene-content polypropylene injection molding tank special-purposed resin

A synthesis method and polypropylene technology are applied in the field of synthesizing special resins for high ethylene content impact polypropylene injection barrels, which can solve the problems of low market supply of products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

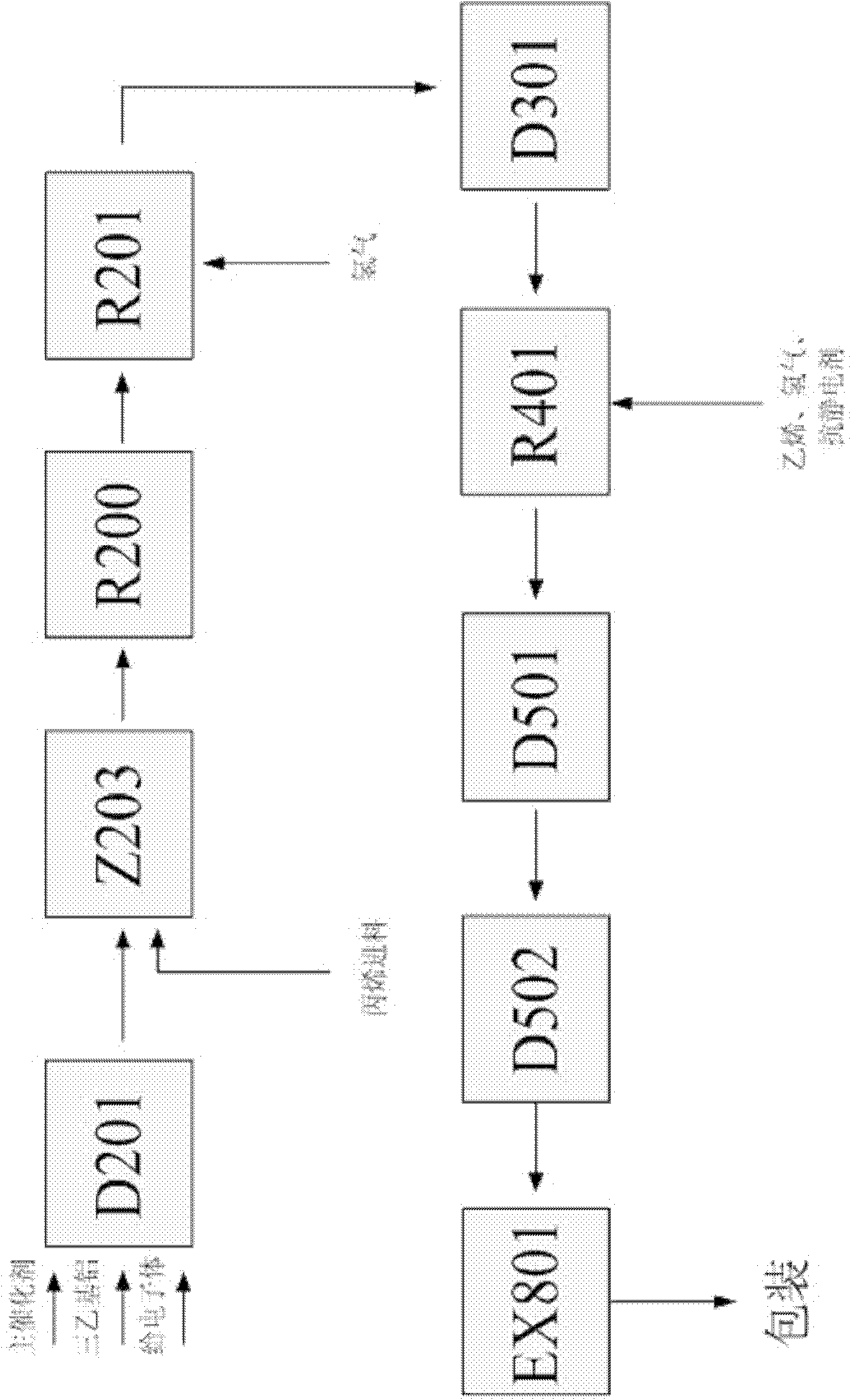

Method used

Image

Examples

Embodiment 1

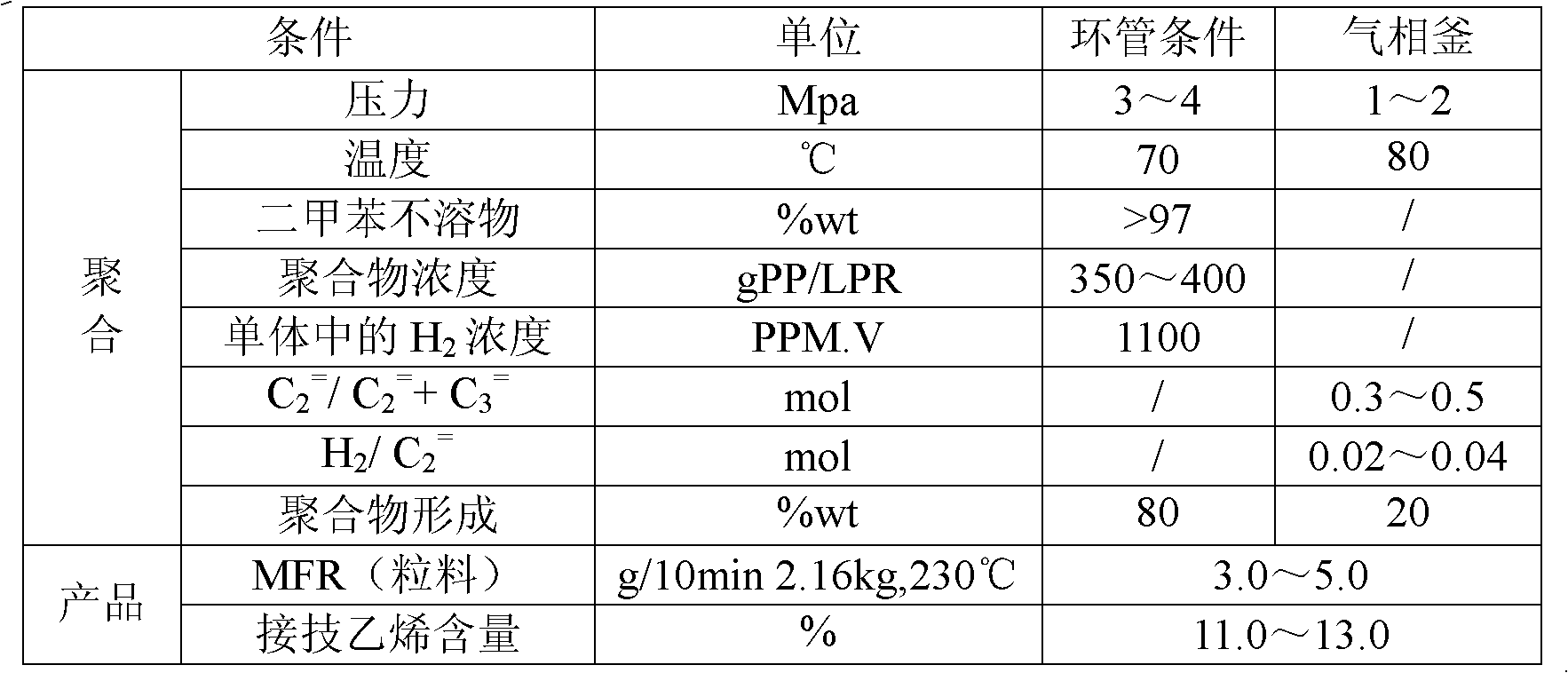

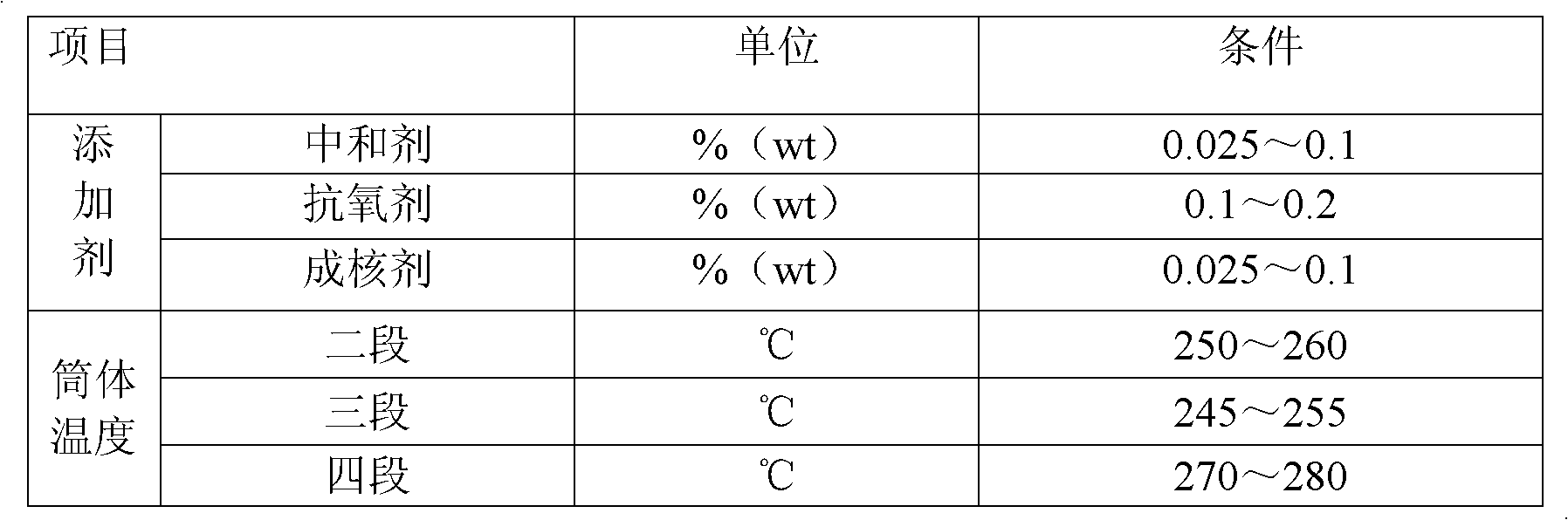

[0036] Device load 7.5t / h: main catalyst (180g / h), electron donor (850g / h) and triethylaluminum (1340g / h) in the pre-contact tank D201 at about 10°C, fully stirred and mixed to form complexation center. The catalyst mixture overflowed from D201 is mixed with cold propylene (20°C, flow rate 5.5-6.5t / h) in Z203 (inline mixer) and then enters prepolymerization reactor R200 at 20°C and 3.4Mpa pressure , reacted for about 4 minutes, and the slurry entered the loop reactor R201. The polymerization operation temperature is 70°C and the pressure is 3.4Mpa. The pre-polymerized slurry, propylene and H to control the molecular weight 2 (1.3kg / h) are input into the loop reactor R201 together, a part of propylene is polymerized, and the remaining liquid propylene is used as the flow carrier of solid PP. The circulation pump makes each component flow at a high speed at a speed of 7-8m / s and fully mixes them uniformly. The slurry concentration is controlled at 50-55%wt. The density of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com